What is the Bearing: Understanding Functions of Bearings, Types, and Applications

Bearings are foundational components in countless mechanical systems, playing a critical role in reducing friction and supporting rotational or linear motion. Whether in industrial machinery, automotive design, or household appliances, bearings ensure efficiency, reliability, and longevity of operations. This article aims to provide a detailed exploration of bearings, clarifying their fundamental functions, breaking down the various types available, and examining their diverse applications across industries. By understanding the mechanics and engineering behind bearings, readers will gain valuable insights into how these essential devices contribute to precision and performance in modern technology.

Types of Bearings

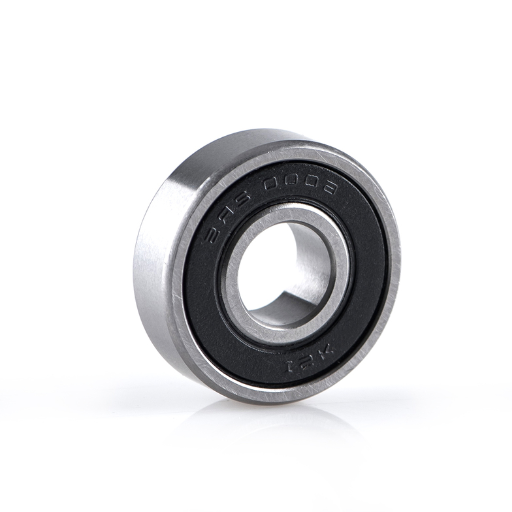

Ball Bearings and Their Applications

One of the most frequently utilized types of bearings to diminish rotational friction and support radial and axial loads is the ball bearing. Because the balls reduce the contact area between the moving surfaces, the friction is decreased, enhancing smoother operation. Typically, the arrangement includes an inner ring, an outer ring, a series of balls, and a cage to hold the balls in place while allowing their rotation. Given the versatility they have in design, ball bearings are used mostly in high-speed applications because they have a better ability to handle moderate load capacities.

Due to their reliability, precision, and dimensional compactness, ball bearings have numerous applications in many industries. Ball bearings find considerable use within the auto industry. They are warranted wherever such motions are smooth and efficient-working gearboxes, engines, and wheels. Ball bearings are also used in industrial machinery, usually for conveyors, pumps, and electric motors, where both radial and axial loads require handling. They are also used in consumer electronics such as computer fans and hard drives, where noise is to be minimized, and smooth operation quantified.

The adaptation of ball bearings to the operational environment is augmented by variations in material and lubrication systems. Stainless steel ball bearings provide high tensile strength and corrosion resistance; hence, they should be applied where the environment is wet or chemically exposed. Ceramic ball bearings find their usage in high-temperature-high-speed environments due to their low weight and thermal stability. This variety allows the ball bearing to meet the specified performance requirements of specific applications, both with precision and reliability.

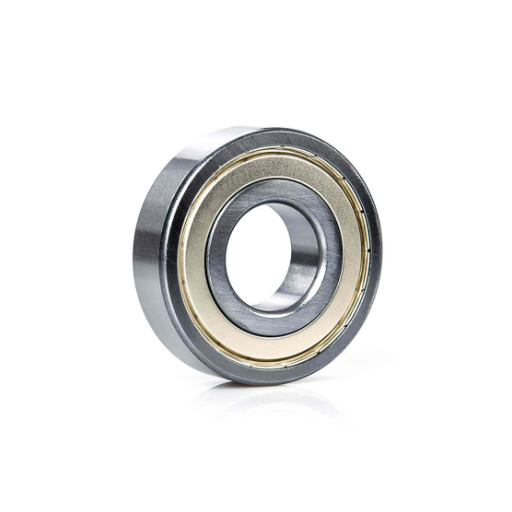

Rolling Bearings: Characteristics and Uses

Rolling bearings are mechanical components that actually reduce friction between rotating parts and thus adequately support axial and radial loads. They come in many varieties, each suited for different operating conditions. Deep groove ball bearings are perhaps the most known among them; they are very versatile and efficient when it comes to high-speed applications with moderate radial and axial loads. Tapered roller bearings, on the other hand, are built for situations where combined axial and radial loads are large, such as automotive wheel hubs or gearboxes.

Cylindrical roller bearings offer high capacity for radial loads and are typical in heavy industry applications or high-speed turbines. On the other hand, spherical roller bearings accommodate misalignments and uneven load distributions, thereby becoming useful in large rotating machinery like paper mills or vibratory screens. The innovations of angular-contact ball bearings that carry both radial and axial load in one direction have furthered their application into precision fields such as robotics and aerospace.

The rolling bearings’ durability and useful life have been extended with the advances in materials and lubrication technology. Incorporation of advanced seals and synthetic lubricants further minimizes wear and contamination to ensure reliable performance even in harsh environments. These aspects make rolling bearings not only indispensable to modern mechanical systems but also an extremely important contributor towards higher system efficiency and reduced downtime in all industries.

Plain Bearings: Functionality and Advantages

Plain bearings, also known as sliding bearings, depend on a relative sliding motion between two surfaces. Unlike rolling bearings that use rolling elements, a plain bearing relies on a thin film of lubrication for support between the surfaces to decrease friction and enable smooth movement. This makes them very favorable in cases where simplicity and strength with little or zero maintenance are desired. They are generally used when there are severe space constraints, the need to support heavy loads, or resistance against shocks and vibrations.

One significant advantage of a plain bearing is its ability to support enormous weights and accommodate offset misalignments while still functioning well. Owing to their simplicity, these bearing types would function under conditions of high or low temperatures or are subjected to corrosive materials the condition that the right materials and lubrication are applied to them. Their main feature: quiet operation with minimum vibration, makes them suitable for industries like automotive, aerospace, and manufacturing machinery.

Bearing performance largely depends on the choice of materials for the plain bearing. Typical materials include bronze, composites, and engineering plastics, each suited to a different range of operating conditions. For example, polymer composite self-lubricating bearings are usually used in situations where regular lubrication maintenance is not practical. This great adaptability, coupled with cheap construction, makes the plain bearing a sort of jack-of-all-trades for various mechanical systems.

How Bearings Function

Mechanics of Bearing Operation

Bearings serve the purpose of diminishing friction between moving parts in a mechanical system to allow smooth rotational or linear motion. At their core, bearings work upon the principle of load transfer, wherein forces are intentionally transferred between components to reduce wear and hence to enhance efficiency. Such transfer mechanisms include the use of interfaces of rolling elements, lubricants, or low-friction materials.

In contrast to roller bearings that use cylindrical or tapered rollers to carry much higher radial and axial loads with a rolling mechanism to lessen friction losses, in plain bearings, surfaces can be in direct contact with each other, either via lubrication or special composite materials coating the surface to reduce friction. Choosing a suitable bearing would hence depend on the type of load, speed, life expectations, and even environmental factors like temperature and contaminant exposure.

A paramount factor in bearing performance is adequate lubrication. Lubrication between the bearing surfaces is essential for minimizing metal-to-metal contact, especially given that friction will cause heat buildup and wear due to particle contamination. Advanced lubricants, such as synthetic oils and solid types including graphite or molybdenum disulfide, have been engineered to extend bearing life under some extreme conditions, like high temperature or corrosive environments.

Modern bearing design, combined with modern manufacturing, allows for tighter tolerances and better load distribution. Stress distribution and thermal behavior modeling are performed using programs such as FEA to optimize them for performance. Also, sensor-equipped bearings are increasingly involved in smart systems to monitor in real time temperature, vibration, and lubrication levels, among others. This leads to predictive maintenance, minimizing downtime, and ensuring operational availability.

Role of Lubrication in Reducing Friction

In mechanical systems, lubrication reduces friction and wear between two bodies in relative motion. When lubricants establish protective films between two contacting surfaces, they diminish wear and heat generation while simultaneously enhancing the overall efficiency of the mechanical components. Conversely, this increases the lifetime of the fittings and equally guarantees optimal energy consumption by the machines. Below are five essential functions and benefits of lubrication while reducing friction:

- Formation of Low Shear Stress Films: Lubricants separate the two surfaces in relative motion by an extremely thin film, mostly termed hydrodynamic lubrication. The presence of this film between surfaces eliminates adhesion due to contact asperitie,s where friction could shoot up.

- Dissipation of Heat: During operation, especially under high loads, considerable heat is generated due to the friction. Lubricants absorb the heat and transfer it away from the contact zones, thus preventing thermal deformation and preserving dimensional accuracy in the components.

- Reduction of Surface Wear: By limiting metal-to-metal contact, lubricants avoid mechanisms leading to abrasive and adhesive wear. This is very important in the durability of equipment subjected to continuous operation, such as engines or gear systems.

- Anti-Corrosion: Most lubricants have anti-oxidation and corrosion-inhibiting properties through the use of additives. By limiting the amount of corrosion present, they aid in maintaining a smooth contact interface, which is crucial in sustaining low friction.

- Increase Load Capacity: High viscosity or specially formulated lubricants, such as extreme pressure (EP) lubricants, improve the ability of the contact surfaces to withstand heavy loads. Under extreme pressure conditions, these lubricants bear the load and protect the surface, thus reducing friction even in severe operating conditions.

Through suitable lubrication, the integration of suitable monitoring procedures will, without a doubt, ensure the dependable and efficient running of mechanical systems, with a resultant reduction in energy dissipation and maintenance cost.

Understanding the Bearing to Rotate Mechanism

The bearing-to-rotate mechanism is the fundamental element of various machinery that lets a particular part rotate smoothly by reducing friction. Designed to bear radial and axial loads with high precision, bearings assure the stability and life of the rotating elements. Such mechanisms depend on the appropriate choice of bearing types—ball bearings, roller bearings, thrust bearings—according to the load and other operating conditions.

Advanced materials and their manufacturing have made the modern bearing more durable and high-performance. Ceramic-coated or hybrid bearings minimize heat generation and wear; hence, they are used for high speeds and temperatures. For instant-condition monitoring, vibration analysis, or load displacement sensing may be employed for predictive maintenance, thereby reducing unexpected downtime.

Much depends on lubrication for the performance of the bearings within the rotating mechanism. The use of synthetic lubricants having specially-tailored viscosity and additive formulations comprises a reduction of internal friction, wear, and heat dissipation. Studies have shown that this kind of lubricant, when optimized, can save up to thirty percent of energy loss, an indication of its importance to efficiency.

An in-depth knowledge of bearing-to-rotate mechanisms will enable engineers to initiate further developments in machine reliability and adaptation to industrial requirements of high-speed, energy-efficient systems.

Materials Used in Bearings

Common Bearing Materials: Steel, Ceramic, and Plastic

- Steel Bearings: The bearing assemblies made of steel witness the greatest use in applications due to the high characteristics of steel in strength, durability, and abrasion resistance. Amongst the numerous types of steels, chrome steel and stainless steel are most commonly used. Chrome steel bears a good reputation for the hardness it derives from the high carbon and chromium content, together with the fatigue resistance that finds application under heavy load and at high speeds. On the other hand, stainless steel is used in conditions on account of corrosion resistance, where moisture or chemical-welding atmosphere exists. Steel type bearings are also known for their utilization in industrial machinery, automotive systems, and aerospace given their operating conditions under extreme environments and maintaining precision.

- Ceramic Bearings: There are some special requirements, and ceramic materials like silicon nitride and zirconia are being applied more and more in bearing applications because of their unique properties. Ceramic bearings offer high-temperature resistance, are lightweight, and provide excellent wear and corrosion resistance. Silicon nitride bearing finds many applications in high-speed rotating systems due to their low density, which minimizes friction and centrifugal forces. Besides, ceramics being electrically insulating makes them ideal in electrical- and magnetic field-sensitive environments. Hence, these industries of electronics, robotics, and high-precision machinery stand to gain greatly from ceramic bearing implementations with respect to performance and life.

- Plastic Bearings: Plastic bearings are lightweight, relatively maintenance-free, and self-lubricating. Commonly used are plastics such as PEEK (polyetheretherketone), nylon, and UHMWPE (ultra-high-molecular-weight polyethylene). These bearings resist corrosion and are used where metallic bearings may fail-Water, chemical, or thermal exposures. Plastic bearings are not appropriate for heavy loads or high speeds. They are favored in applications where sound attenuation, weight reduction, and economy constitute important factors-medical constructions, food processing machinery, and consumer products.

Every material has its pros and cons, which allow the engineer to select the type of bearing that best fits the operational constraints, performance requirements, and environmental factors. The incessant evolution in material science opens newer avenues for improving bearing performance and reliability.

Benefits and Limitations of Each Material

Steel will be rusty, but stainless steel will resist corrosion and will be weaker. Polymers are light but less durable, whilst ceramics will stand the heat and will be costly.

|

Material |

Benefits |

Limitations |

Key Use |

|---|---|---|---|

|

Steel |

Strong, affordable |

Rusts, corrodes |

Manufacturing |

|

Stainless |

Corrosion-resistant |

Lower strength |

Wet environments |

|

Polymer |

Lightweight, insulates |

Less durable |

Cleanrooms |

|

Ceramic |

Heat-resistant, low-friction |

Expensive, low load |

Aerospace |

Impact of Material Choice on Bearing Performance

Such aspects as load capacity, durability, and efficiency are dramatically influenced by the materials chosen for the manufacturing of bearings. Some steels are widely employed for uses that require superior strength and a relatively cheaper price. Hence, steel is the best choice for a few applications requiring excellent mechanical performance under heavy load, but prone to corrosion in a humid environment oran aggressive chemical environment. Stainless steels, as the next step, confer the highest corrosion resistance and are therefore recommended for marine or other salt, saltwater-prone environments, losing some strength in relation to the ordinary steels.

Polymers, conversely, provide competing advantages in terms of being lightweight and insulating. In other words, for applications demanding low static loads and therefore electrical insulation, in environments containing sensitive equipment such as cleanrooms, these materials are suitable. Their lower robustness, however, does not allow them to be used in heavy-duty working conditions.

Ceramics are costly but have excellent thermal resistance and low friction, which makes them suitable materials for aerospace and precision instruments operating at high speeds and high temperatures. Technically, these materials have advantages, but their brittleness and expensive production costs limit their practical applications.

This optimization of bearing performance finally involves a thorough consideration of the operational requirements, the environmental conditions, and the inherent compromises demanded by each material. This balancing endeavor guarantees optimal efficiency and bearing reliability tailored to the specific industry where it finds application.

Maintenance and Care for Bearings

Practical Tips for Bearing Maintenance

Bearing maintenance and care are paramount to ensuring maximum operational longevity and preventing premature failure. Below are some helpful tips:

- Ensure Correct Lubrication: Proper and adequate lubrication is essential to reduce friction and wear. Use the lubricant specified by the manufacturer, which could be either grease or anti-wear oil. Excess lubrication leads to heat buildup, while less-than-required lubrication leaves the bearing without adequate protection. Be sure to check the lubrication periodically and discard it whenever contaminated or degraded.

- Monitor Operating Conditions: Monitor processes while in use for temperature, vibrations, noise, etc. Abnormal conditions in which temperatures or noise rise may point to misalignment, excessive load, or contamination of some sort. Use sensors or vibration analyzers for proper fault diagnosis.

- Prevent Contamination: Dirt, moisture, or corrosive substances become contaminants entering the assembly and hamper the bearing’s performance. Protect bearings adequately against contamination via proper seals and shields, and keep the work environment clean during installation and maintenance activities.

- Wear and Damage Inspection: Bearings should be inspected every now and then for signs of physical wear, cracks, pitting, and discoloration; these temporary signs will guarantee the recognition of early damage. Bearings shall be replaced if found worn beyond acceptable limits, owing to the enormous financial loss that could be incurred because of preventing the loss in its early stages.

- Installation Evaluation: Improper installation could cause damage to the bearing and undercut the operational efficiency thereof. Wrong installation methods can be applying the pressure unevenly or holding the tools incorrectly. Special care must be taken when using tools such as bearing pullers and bearing installers to prevent misalignment and structural strains during installation.

- Adhere to Load and Speed Ratings: If bearings are run farther than load and speed ratings, they become subject to very early failure. Make sure that the bearing is sized correctly and fits adequately for application-specific requirements, and strictly follow manufacturer specifications.

Following these maintenance considerations, combined with the application of advanced diagnostic techniques, shall keep users at their best regarding performance reliability and reduced operational costs, and enable a greater bearing life.

Common Issues: Wear and Friction in Bearings

Wear and friction in bearings are among the major sources of performance degradation and downtime in mechanical systems. One of the principal wear phenomena occurs due to a lack of lubrication and thus excessive contact of bearing surfaces, leading to erosion of materials and an increase in roughness. Wear thus increases especially due to contamination of the bearing by external particles, which may be dust, debris of any kind, or moisture, thereby freezing the conditions inside the assembly. Localized wear can also occur if improper mounting methods or conditions of misalignment are allowed to be present; these would lead to uneven load distribution.

Friction, by its very nature, chugs up the heating of a bearing and, consequently, the operating temperature. When operating temperatures go high, the bearing material may lose its structural integrity as it starts to undergo dimensional changes or microcracks. Besides, high friction causes a lot of wastage of energy and decreases the efficiency of whatever system it is in, thus resulting in total obstruction of the system if allowed.

There should be a good lubricating system applied with various types of lubricants having viscosity and thermal stability adapted to their applications. Uneven loading can be prevented by precision assembly and regular inspection of alignment. Good sealing can further be ensured to guard against contamination. Condition-monitoring will enable early detection of anomalies before they become critical failures, and would include vibration analysis and thermal imaging for wear and friction detection purposes.

Lubricants: Choosing the Right Type

Choosing the right lubricant for a particular application implies a full understanding of the operating conditions, such as temperature, load, speed, and working environment. The viscosity grade is probably the most important factor concerning the lubricant’s formation of a protective film. High-viscosity lubricants are suitable for applications with low speeds and high loads; on the other hand, those with lower viscosities are to be used by equipment running at high speeds due to the internal friction produced by higher viscosities.

Thermal stability and oxidative resistance are other properties of significance in cases where the systems are exposed to relatively high temperatures, as they maintain lubricant stability during the period and performance. Hence, the selection of the lubricant shall also consider additives, depending on the environment, such as antiwear additives, corrosion inhibitors, and extreme pressure (EP) additives.

Under such inconsistent working conditions, synthetic lubricants perform better than mineral oils in tolerance to temperature and longevity. Choosing the same also rests on how it is compatible with the material and the components, as well as its low-cost maintenance. On the environmentally sensitive front, traction is growing toward bio and biodegradable lubricants as they support environmental measures without compromising on performance standards.

The analysis and appraisal of lubricant performance on a routine basis, such as with spectroscopic and tribological analysis, can facilitate ultimate machine efficiency and early avoidance of wear, leading to the general reliability of operations.

Advancements in Bearing Technology

Smart Bearings with Sensors

With advanced sensors, smart bearings prove to be the latest for condition monitoring and predictive maintenance. The sensors inside the bearing assembly may measure temperatures, vibrations, pressures, loads, etc., in real time. This data is then sent to centralized systems or cloud platforms, where advanced algorithms and machine learning models are applied to detect anomalies and track performance changes.

The use of this technological development in an industry means early disruptions are detected; thus there will be little to no issuance of unplanned downtime or catastrophic failure. For example, vibration analysis can be used to find misalignment or bearing fatigue, while temperature checking ensures good lubrication and prevents overheating. Some systems of smart bearings feature wireless communication protocols, which adds to their rapid integration into IIoT frameworks.

Such technological breakups along enhance the operational efficiency of a plant and further extend the life of machinery through maintenance schemes based on data. An approach of maintenance becoming proactive in nature will certainly bring about savings, better safety, and reliability. These are especially crucial in manufacturing, aerospace, automotive, and the energy sector.

Eco-Friendly Bearing Designs

The eco-friendly bearing designs are considered pivotal in the advancement of sustainable engineering as they cater to the growing demand for environmentally friendly solutions. Such bearings are manufactured using low-impact materials, biodegradable polymers, or recycled metals, greatly minimizing their carbon footprint from production. The lube innovations take into account environmental considerations, with dry or solid lubricants and bio-based oils, thus avoiding the contamination caused by conventional lubricants.

Energy efficiency is another key consideration of eco-bearing design. Advanced geometries combined with modern coatings reduce friction within these bearings and systems-they become more efficient subjectively and lose less energy to internal friction. Improvements of this kind are extremely significant for energy-intensive sectors such as manufacturing and transportation because even a slight improvement in efficiency may prove big in energy savings over the long run.

Also considered with lifecycles are better bearing designs: making bearings that hold longer can be recycled easily. This further promotes the idea of a circular economy, where application and operational life are extended, and materials used are easier to recover and reuse. All these advancements together show how eco-friendly bearings push for sustainability and cost-effectiveness, the long-term utility of which will benefit not only industries but the environment as well.

Future Trends in Bearing Technology

Continual bearing technology evolution will be driven by advancements in material science, digital integration, and ultra-precision engineering. Among the key trends is the increasingly gaining unparalleled popularity: production and use of hybrid bearings that spin out of conventional steel materials along with ceramics. These offer high performance above high speed and temperature, thereby enhancing, to some degree, the operational efficiency and helping in the reduction of energy consumption. Self-lubricating bearings are also becoming popular since they require very little maintenance and require no use of external lubricants, thereby supporting cost savings and environmental conservation.

For another, IoT and sensor technology applications found their innovative implications within bearing systems. Smart bearings with embedded sensors can monitor vital parameters such as temperature, vibration, and lubrication in real time. These smart bearings pave the road for predictive maintenance mechanisms, minimizing unplanned machine downtime while hitherto maximizing the service life of equipment, the powered analytics of which gives a new rise to very fast processing and creating worthwhile insights.

The incorporation of advanced manufacturing methods aimed at bearing production, such as additive manufacturing-3D printing, is gaining some importance as well. This layer-by-layer procedure allows for bearing components customized to an unusually high degree-very light and complex-multifaceted geometry bearing components that until now had no fabrication possibilities attached to their complexity in their geometric nature. Uniting this with the environmental, the golden stage for recyclable materials and energy-conserving production processes focuses bearing technology toward sustainability, performance optimization, and intelligent system integration. These will undoubtedly be at the forefront in driving and modifying reliability, thus paving the way to efficiency across time in innumerable industries.

Frequently Asked Questions (FAQ)

Q: What is the bearing?

A: A bearing refers to a machine element that supports and guides rotating shafts. It reduces friction between two surfaces, allowing for smooth movement and increased efficiency in various mechanical applications.

Q: What are the different types of bearings used?

A: Bearings typically include rolling element bearings, thrust bearings, and magnetic bearings. Each type serves a specific purpose based on the load and type of operation, such as supporting radial loads or thrust loads.

Q: How do bearings reduce friction?

A: Bearings reduce friction by creating a rolling motion between the inner and outer races. This allows the rolling elements, like balls or rollers, to keep the moving parts separated, minimizing wear and energy consumption.

Q: How can I select the right bearing for my application?

A: To select the right bearing, consider factors like load-carrying capacity, type of movement (linear or rotational), and environmental conditions. Understanding the thrust load and the amount of energy consumption can also guide your decision.

Q: What is the service life of a bearing?

A: The service life of the bearing depends on factors such as the load applied, speed of operation, and maintenance. Proper lubrication and selection of materials can prolong the lifespan of bearings significantly.

Q: How do magnetic bearings work?

A: Magnetic bearings support a rotating shaft using magnetic fields, eliminating physical contact between parts. This technology reduces friction and wear, making it ideal for applications where precision and cleanliness are critical.

Q: What are thrust bearings used for?

A: Thrust bearings are specifically designed to handle axial loads, supporting the shaft in applications where forces act parallel to the shaft. They are crucial in machinery where misalignment can cause significant wear.

Q: Why were wooden bearings used by ancient civilizations?

A: Ancient Egyptians used wooden bearings for their simplicity and availability. These primitive bearings facilitated the movement of heavy objects, showcasing early engineering principles in mechanical design.

Q: How do bearings support both radial and thrust loads?

A: Bearings support both radial and thrust loads by utilizing their design, which includes inner and outer rings and rolling elements arranged to accommodate different types of loads effectively. This versatility makes them essential in many applications.

Q: What role do bearings play in modern mechanical engineering?

A: Bearings play a critical role in mechanical engineering by enabling the smooth operation of machinery, reducing friction, and increasing efficiency. They are widely used in various industries, from automotive to aerospace, ensuring the reliable performance of moving parts.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8