Unlocking the Mystery: What Does a Ball Bearing Look Like?

Ball bearings are ubiquitous components that quietly enable the seamless functioning of machinery in nearly every industry, yet they often go unnoticed. From automotive engines to household appliances, these small and intricate devices play a critical role in reducing friction, supporting loads, and ensuring smooth rotational motion. But have you ever stopped to wonder what a ball bearing looks like and how it works? This article will take you beyond the exterior of these seemingly simple devices to uncover their intricate design, components, and functionality. Whether you’re an engineer, a tech enthusiast, or simply curious about mechanical marvels, understanding ball bearings is essential for appreciating how they drive efficiencies in modern technology.

What are the Ball Bearing Components?

Understanding the Bearing Balls and Their Function

Bearing balls make an essential component of ball bearings: they usually enable the frictionless sliding motion of parts moving relative to each other, either smoothly rotating or linear motion. Spherical elements are usually steel, ceramic, or other heavy-duty materials for durability and high functioning under several loads and speeds. Their exceptionally hard nature and accurate geometry allow these spheres to minimize the contact area, providing very little resistance to wear over time.

The bearer of the load is a function of the bearing, carrying the translation of the load between the inner and outer rings of the ball bearing. While being carried, they move along the raceways- grooved tracks in the rings- facilitating motion and hindering as little friction as they can. The rolling action is far more efficient in rendering less friction compared with sliding, and so ball bearings are used in highly precise and reliable applications.

The size, material, and surface finish of the bearing balls will directly affect the efficiency and longevity of the ball bearing. Bearing balls with a smaller size would minimize friction, but cannot support heavy loads. On the other hand, bearing balls of larger sizes can resist heavy loads while contributing to high friction. The choice of material will change thermal conductivity or corrosion resistance. Hence, these must be chosen considering the actual need of the machine or system where the ball bearings will be used.

The Role of Inner and Outer Races

The inner and outer races serve as ball bearing components that guide and support the rolling elements, thereby loading the bearing and permitting smooth operation. The inner race is mounted on and rotates with the shaft, while the outer race is fixed inside the housing or casing. A bearing in which interaction between the races and balls takes place reduces friction and supports radial or axial loads, depending on design.

The geometry and material of the races have a direct effect on the performance and durability of the ball bearing. The races are usually precision-ground to provide a smooth and uniform path for the balls to roll without undue wear or energy losses. Materials of the highest quality, such as hardened steel and ceramics, are generally used for the races to withstand applied forces, avoid deformation, and work at high temperatures. A further aspect of surface finishing is its ability to reduce any imperfections that could lead to premature failure.

The fit of the races with their mating components, such as the shaft and housing, also determines the stability of the overall system. A correct interference fit will prevent slippage and allow alignment during operation. Should the races be misaligned or incorrectly fitted, uneven load distribution will occur, thereby causing further wear and, eventually, failure. Consequently, the inner and outer races should be designed, manufactured, and installed with the utmost precision so that the bearing can perform optimally and enjoy a long operating life.

How Do Rolling-Element Bearings Work?

Rolling-bearing elements reduce friction between moving parts and support the radial and axial loads, such as balls or rollers. The bearing comprises inner and outer races, rolling elements, and a cage for holding them spaced apart. When rolling-element bearings operate, the rolling elements roll between the two races, minimizing the contact area, thereby considerably reducing friction compared to sliding systems.

Here, the rolling mechanism stands for its efficiency: resistances created by rolling elements are minimal; hence, rolling-element bearings create less heat and are capable of operating at high speeds, in contrast to plain bearings. Also, while rolling elements distribute loads evenly over the various components, plain bearings do not ensure smoother operation and longer life for the bearing. Hence, they are critical for precision-driven applications such as industrial machinery, aerospace, and transportation.

Proper lubrication ensures the operational efficiency of rolling-element bearings, successful working, and longer reliability. Lubricants protect from corrosion and wear, along with dissipating the heat created by bearing operation. Depending on the magnitude of the load, the speed, and the environmental conditions, a different type of lubricant is needed. Without lubrication or with improper lubrication, the operational efficiency of the bearing system decreases while accelerating its deterioration. Thus, continuous maintenance is of utmost importance to keep the bearing functioning well, preventing any mechanical failure.

How are ball Bearings used in Various Applications?

Why Ball Bearings are Used in Machinery

Because of the capacity of ball bearings to reduce friction between rotating or moving components, they are integral to machinery. Their design- well, hardened steel or ceramic spheres held between inner and outer raceways- ensures the smooth transfer of loads with minimal energy loss. They accommodate radial as well as axial loads and thus have a wide use in various mechanical applications.

One of the advantages arises from their being able to rotate at very high speeds with little wear, very critical in applications of electric motors, turbines, and pumps. Their precision construction also affords smooth operation of the unit, which otherwise becomes semi-destructive through vibration or noise. Advancements in material science have also led to corrosion-resistant and heat-tolerant bearings, allowing their use in harsh environments such as aerospace, marine, etc.

The industry further implies a growing demand for ball bearings of longer life and greater efficiency are especially in industrial areas conscious of energy conservation and equipment lifetime. Maintenance and ensuring proper lubrication, however, are most essential for realizing the entire life period of ball bearings, neglect of which usually brings about premature failure or damage to the entire system in machinery. This delves into the exploration of their being as an active support pillar for smooth functioning, as well as the long life of industrial systems.

The Importance of Ball Bearings in High Speeds

Ball bearings find a significant place in the high-speed operations of various machines and industrial systems. The bearing is designed to reduce friction among components in relative motion so that the rotational speed reaches maximum levels without causing heat build-up or undue wear. Extremely crucial for their functioning remains the commercial-grade precision of the raceways, balls, and cages. Bearing-usability high-speed applications require ball bearings having high degrees of tolerance, surface finish, and materials capable of resisting high stresses from operation.

Apart from design, lubrication is the other most important consideration in high-speed operations. Exact lubrication of bearings, be it with grease or oil, reduces friction and hence dissipates heat, helping the bearings maintain performance levels over time. The lubricating systems are often made more complex in the high-speed environment to bring about the highest efficiency possible while limiting thermal rises.

Additionally, bearing materials also tend to influence the ball bearing performance in high-speed conditions. For instance, ceramic hybrid ball bearings perform better due to their lighter weight, lower thermal expansion, and greater wear resistance. As materials are implemented along with advanced features that bring about ultra-low vibrations from cage designs and better sealing technologies, the bearings, in turn, become more dependable and last longer even through extreme speeds.

With recent developments in bearing technology showing the rising use of smart bearings equipped with sensors for real-time monitoring of temperature, speed, and vibrations, predictive maintenance has become possible, hence reducing catastrophic failures, while resulting in an increase in the productivity of high-speed machinery. This stance in favor of modernization only endorses the relevance of ball bearings as a crucial factor contributing to the performance and life of industrial systems working at high velocities.

Exploring Different Types of Ball Bearings

Ball bearings are an integral component in modern bearings, offering versatility and capability under varying conditions. The foremost types of ball bearings are deep groove ball bearings, angular-contact ball bearings, self-aligning ball bearings, and thrust ball bearings, each designed to carry out a specific operational function.

- Deep Groove Ball Bearings: This is the most typical type, having a rather simple design based on deep raceway grooves to accommodate both radial and axial loads. They are generally used in electric motors, conveyors, and household appliances because of their longevity, low levels of noise, and little maintenance.

- Angular Contact Ball Bearings: An axial and radial load is forced simultaneously, while the angular contact ball bearing produces a contact angle that enhances the load-carrying capacity. The bearings can be used in high-speed and high-precision applications typified by machine tools, pumps, and turbines.

- Self-Aligning Ball Bearings: Self-aligning bearings contain two rows of balls and one common spherical raceway in the outer ring. These bearings accommodate shaft misalignment concerning the housing and hence relieve systems under consideration, which may induce shaft deflection or consider mounting error. They find their application in gearboxes, agricultural machinery, and textile equipment.

- Thrust Ball Bearings: Thrust ball bearings provide the means to support pure axial loads. These can very well be used in light axial loads. They require very high axial precision and are mostly used in automotive steering, rotary tables, and crane hooks.

Bearing technology is still evolving, and many of the aforementioned types have been improved by many new technological innovations, such as ceramic balls to reduce friction, advanced lubrication methods, and embedded monitoring sensors. These technological breakthroughs promise optimized performance, longer life, and high reliability even under extreme loading and high-speed conditions.

What are the Benefits of Ball Bearings?

How Bearings Support Efficient Operation

Bearings are used to improve the efficiency of mechanical systems by reducing friction between moving parts. Bearing friction is the loss of energy in a system due to heat generation and wear, so that equipment can run more smoothly and reliably. Moreover, bearings provide proper rotation or linear movement so that the components remain aligned under different load and speed conditions. Standard operation and low system downtime depend on this proper movement, whether it is a medical instrument or an industrial machine.

With modern technology bearing design advances, bearing design principles have been furthered to improve efficient operation. Ceramic ball bearings are lighter than steel and hence are quieter and allow for a longer life. Developments in lubrications, including solid lubrications or special extremely low friction oils, also contribute to ensuring their success with, at best, limited periods between renewals. Temperature-resistant materials and corrosion-resistant coatings, on the other hand, provide reliability to bearings in extremes such as high temperature outside, high humidity, or chemical exposure, which standard components would not tolerate.

Embedded sensor technology in bearings is yet another innovative feature that boosts the performance and reliability of modern-day bearings. Embedded sensors measure parameters such as temperature, vibration, and rotational speed and provide the data needed for the development of predictive maintenance strategies. The proactive assessment gives operators the ability to detect probable failures before they arise in actuality, thus maximizing machine uptime and curtailing downtime. The deployment of smart features turns out to be just one example of how bearings can transcend the generic notion of passive mechanical support toward actively supporting the efficiency and sustainability of advanced mechanical systems.

The Benefits of Ball Bearings in Reducing Friction

Ball bearings reduce friction and increase the efficiency of mechanical systems, allowing smooth and controlled relative motions between components. Because of their spherical design, there is little contact area and, thus, lower rolling resistance. Given below are five benefits of ball bearings in reducing friction:

- Improved Energy Efficiency: By reducing friction, ball bearings reduce the amount of energy lost to resistance while in operation. For example, it has been observed that depending on the application, high-quality ball bearings can help in energy efficiency by up to 30% in machinery in rotation.

- Extended Lifespan of Components: The low-friction nature of ball bearings reduces wear and tear on mechanical components. This ensures maintenance costs go down and downtime is reduced across the life of the machine.

- Higher Operating Speeds: These ball bearings can operate at high speeds with relatively low heat generation from friction. Such features make them especially useful in high-speed applications like turbines, fans, or automotive systems, where operational efficiency and precision count.

- Reduction of Heat and Noise: Less friction means less heat generation during operation, thus thermal stress on system components is decreased. Ball bearings also help to keep things quiet by rolling along, a lot quieter than sliding contacts.

- Consistent and Reliable Performance: Ball bearings share the load evenly and maintain consistent performance across conditions. Such reliability is crucial in industries where precision is dependent on performance, like aerospace and robotics.

By having access to these factors, ball bearings have become synonymous with the performance, efficiency, and sustainability of modern machinery.

Why Ball Bearings are Essential Components in Engineering

The engineering field would be empty without ball bearings, as they help in reducing friction and efficiently handle both radial and axial loads. Their importance further elevates in high-speed applications, wherein utmost emphasis lies in reducing energy loss and wear. Developments in materials have created ceramic and hybrid ball bearings that, existent contrary to steel bearings in the past, upright the bearing in terms of thermal stability, corrosion resistance, and life span.

Besides, owing to advanced manufacturing technologies, ball bearings can now be produced with such low tolerances that they can be almost directly integrated into state-of-the-art systems. For example, EVs use low-friction ball bearings that reduce drivetrain losses, which in turn increases battery range. In aerospace applications, lightweight and high-precision bearings reduce fuel consumption and aid flight stability.

Apart from all this, the recent industry reports cite the growing global ball bearing market with regard to profitable volumes fueled by the demand for energy-efficient machines and the expansion of renewable energy technologies such as wind turbines. Advanced lubricant and sealing technologies provide a means to further increase the life of ball bearings, thereby proving their necessity in sustainable engineering. This combination of durability, precision, and efficiency best epitomizes why ball bearings continue to sit firmly at the crux of modern engineering solutions.

How Does a Roller Bearing Differ from a Ball Bearing?

Comparing Roller and Ball Bearings

Ball bearings are better suited for high speed and light load, while roller bearings are better suited for heavy load and slow speed.

|

Aspect |

Ball Bearings |

Roller Bearings |

|---|---|---|

|

Load Capacity |

Light |

Heavy |

|

Speed Range |

High |

Low |

|

Contact Type |

Point |

Line |

|

Friction Level |

Low |

Moderate |

|

Strength |

Moderate |

High |

|

Alignment |

Flexible |

Rigid |

|

Usage |

Motors, tools |

Mining, construction |

|

Design |

Spherical |

Cylindrical, tapered |

Applications of Cylindrical Roller Bearings

Industrial and mechanical applications encompass enclosing any load, and here are details and instances that emphasize their significance:

- Electric Motors: Cylindrical roller bearings find increasing utilization in electric motor applications as they handle exceedingly large radial loads with relatively low friction. These bearings are suitable for high-speed applications and always give good performance during continuous operation. With newer designs, they consume less energy and are subject to reduced wear, hence giving a much longer life to the motor.

- Gearboxes: Gearboxes find preponderance of bearings whenever the conflicting space requirements demand a compact, high-load component. Cylindrical roller bearings support huge radial forces generated during gear meshing and are made to bear misalignment with practically insignificant effect on their performance, hence reliable in demanding environments.

- Wind Turbines: High-performance cylindrical roller bearing mechanisms are of utmost importance in wind turbines, encompassing main shafts and gearboxes. Their features of bearing axial and radial forces of variable magnitude place them among the important elements for renewable energy. This gives fuel to the operational efficiency, whereby the turbines operate consistently under harsh weather conditions.

- Steel Mills: In the steelmaking industry, cylindrical roller bearings in rolling mills are heavily loaded with radial forces and designed for unfriendly operating environments. Bearings are built to extremes: for high temperatures, heavy contaminations, and heavy-duty cycles, ensuring continuous production with minimum downtime.

- Railway Axles: These cylindrical roller bearings are used in the railway systems for supporting axle loads and absorbing heavy shocks through heavy impacts during operation of the train. It is the durability and anti-friction qualities of cylindrical roller bearings that provide extended periods of maintenance, thereby achieving high-cost efficiency to reliable performance on high-speed rail networks.

The foregoing applications highlight the versatility and importance of cylindrical roller bearings in facilitating industrial efficiency and sustaining systems of high performance in varied disciplines.

When to Use Thrust Bearings?

To thrust bearings, axial loads and parallel forces act on the shaft in applications relatively essential. Thrust bearings find operation in machinery where correct alignment and higher load capacities are required, for instance, automotive transmission, marine propeller shafts, and heavy industrial equipment. Automotive transmission thrust bearings stabilize gears under load for smooth and efficient power transfer.

Thrust bearings may be used wherever rotational elements must resist heavy axial forces with practically little friction and temperature increase. These bearings can consist of rolling elements, such as washers or rollers, and can carry any quantity of axial capacity, depending on the type employed (e.g., ball thrust bearings or cylindrical thrust bearings).

Improvements in materials and lubrication have increased the performance of thrust bearings, thus increasing their service life and reliability, even under extreme operating conditions. By choosing the correct thrust bearing with a well-designed load rating and materials, engineers are able to improve the working efficiency and ensure the design works adequately in critical high-stress operations.

What are the Different Bearing Types?

Characteristics of Deep Groove Ball Bearings

Deep groove ball bearings are one of the most common kinds of rolling bearings employed in applications and are capable of strong performance. These bearings have very deep raceway grooves that allow very high-speed operations and carry significant loads; hence, they carry both radial along axial loads. Low-friction design features levels of efficient energy transmission with less heating, thereby improving the application’s longevity.

When manufactured from hardened steel or advanced ceramics, these deep groove ball bearings develop greater strength to resist envisaged operational wear and high temperature. The precision finish on the inner and outer ring allows the accommodation of misalignments to some degree, to be adaptable for various applications. Further, shielded or sealed types offer a high level of protection against contamination by dust, particles, and moisture, making them suitable where working conditions are severe.

Lubrication technology advancements in these bearings have enhanced their functioning under light and heavy operational loads to allow for less maintenance over a long period of time. Deep groove ball bearings are used widely in picturesque applications where their performance stands on low noise and high speed within electric motors, household goods, automobile attachments, and heavy industry installations.

Understanding Angular Contact Ball Bearings

Angular contact ball bearings are designed uniquely to take both radial and axial load, usually at higher load capacities when compared to standard ball bearings. Contact angle is considered an important parameter for the functioning of these bearings. The term “contact angle” is derived from the angle existing between the line of action of the load transmitted through the balls and the radial plane of the bearing. The contact angle with standard configurations of 15°, 25°, or 40° can be changed purposely depending on the capacity of axial loads the bearing is supposed to take The larger the contact angle, the larger the axial load that can be taken by the bearing. Bearing configurations include single-row, double-row, back-to-back, or face-to-face arrangements to meet such differing directions of resultant loads.

Because of improvements in materials technology and manufacturing technology, angular contact ball bearings have undergone great improvements in terms of durability and precision. Manufacturers of recent days more often use very good steels, hybrid ceramic materials, or further polymers for improved wear resistance, low friction coefficient, and high speed. Lubrication systems via synthetic oils and grease compounds are provided according to the critical conditions assumed for the bearings, so as to maximize the service life while assuring the best possible working performance in extreme environments such as high temperature or at high speed.

It is with special reference to aerospace, automotive, and robotic industries where motion precision, energy, and load reliability are required. For instance, motor and gearbox components in the electric vehicles would be barely supported with friction torques by angular contact ball bearings, thereby ensuring system efficiency. Because of applications to carry load in various directions and being precise, angular contact ball bearings are crucial in recent engineering design that requires utmost performance and longevity.

Frequently Asked Questions (FAQ)

Q: What is a ball bearing, and how does it work?

A: A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races. Ball bearings are designed to support axial and radial loads, allowing the wheel to rotate freely with minimal friction.

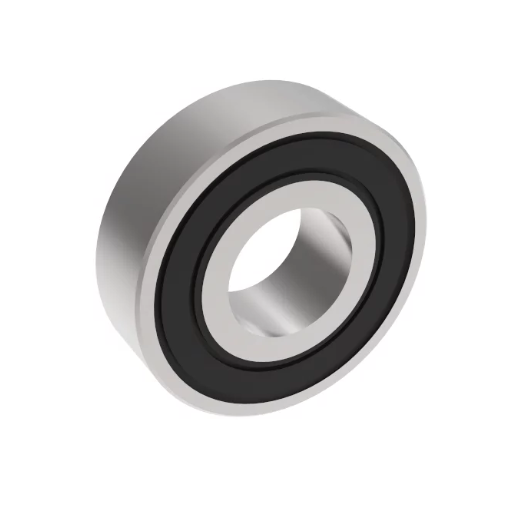

Q: What does a typical ball bearing look like?

A: A ball bearing typically consists of an outer ring, an inner ring, a series of balls, and a cage to hold the balls in place. The balls in ball bearings are usually made of steel, though ceramic bearing balls are also used in some applications.

Q: What are wheel bearings, and why are they important?

A: Wheel bearings are an essential component in vehicles, allowing the wheel to rotate smoothly. They are commonly used in automotive applications and are crucial for maintaining proper alignment and handling of the vehicle.

Q: What are the various types of ball bearings available?

A: Ball bearings come in various types, including single-row bearings, angular contact bearings, and mounted bearings. Each type is designed for specific applications and load requirements.

Q: How do ball bearings differ from other types of bearings?

A: Unlike other types of bearings, ball bearings feature rolling balls to reduce friction between the bearing races. This design is particularly effective for high-speed applications, where reduced friction and noise are crucial.

Q: What materials are used in ball bearings?

A: Ball bearings are commonly made from bearing steel, which offers durability and strength. Additionally, hybrid ceramic bearings use ceramic bearing balls for improved performance in high-speed or high-temperature environments.

Q: What are some common causes of bearing failure?

A: Bearing failure can occur due to several factors, including improper installation, contamination, inadequate lubrication, and excessive loads. Regular maintenance and using the correct type of bearing for the application can help prevent failure.

Q: Where are ball bearings most commonly used?

A: Ball bearings are found in a wide range of industrial applications, including automotive, aerospace, and manufacturing equipment. They are also used in household appliances and electronic devices, where smooth and efficient motion is required.

Q: How do bearing manufacturers ensure the quality of ball bearings?

A: Bearing manufacturers use precise engineering and quality control processes to ensure the reliability and performance of ball bearings. This includes material selection, heat treatment, and rigorous testing to meet industry standards.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8