Understanding Lubricating Oil: Its Importance, Types, and Applications

Lubricating oil is a crucial component in the seamless operation of countless machines and systems, playing a pivotal role in minimizing friction, reducing wear, and optimizing performance. From heavy industrial machinery to automotive engines, the right lubricating oil ensures efficiency, longevity, and reliability in mechanical processes. This article dives into the fundamentals of lubricating oil, exploring its significance, the various types available, and their specific applications across industries. Whether you are an engineer, a technician, or simply curious about the science behind smooth mechanical function, this guide provides a comprehensive overview to deepen your understanding of this essential substance.

What is Lubricating Oil?

Definition and Composition of Lubricating Oil

Lubricants, per se, oils, as they are often called, decrease friction between moving mechanical components; said another way, they decrease frictional wear and tear on those machine parts, dissipate heat, and prevent rusting. In a more general sense, lubricating oil serves as an essential medium that helps keep mechanical systems running efficiently and performing well, as well as ensuring longevity.

Lubricating oils contain two major elements: base oils and additives. Base oils are the basic element, commonly obtained from crude oil by refining (mineral-based) or, in other cases, synthetic chemical compounds are combined (synthetic-based). These base oils provide the principal physical and chemical properties, i.e., viscosity and thermal stability, to the lubricant. Additives are then added to enhance or provide desirable attributes, such as anti-wear properties, detergents, dispersants, corrosion inhibitors, and viscosity modifiers, so that the lubricants may serve their purpose well in specific operating conditions.

There may be many formulations of lubricating oils depending on their application; for example, automotive engine oils are designed to deal with high temperatures and varying pressures, while industrial lubricants are for machinery under continuous loads or in extreme environments. Exactly how base oils and additives are blended determines if the lubricant will fulfill all performance criteria and satisfy regulatory requirements, therefore proving indispensable to the smooth operation of mechanical systems used in various industries.

The Role of Lubricating Oil in Machinery

Lubricating oil performs several critical functions for the efficient operation and smooth running of mechanical systems. These functions are achieved through a combination of base oils and special additives to enhance performance. Here are five major functions of lubricating oil in machinery:

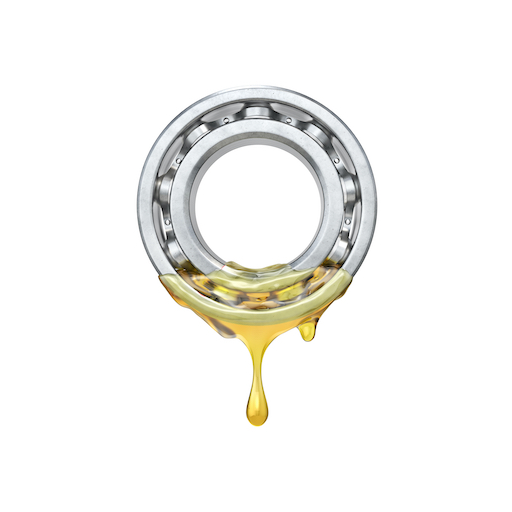

- Friction Reduction: Lubricating oils reduce friction between two relatively moving parts in a machine, causing wear, thus reducing friction and wear on parts and increasing their life span. For instance, in high-speed bearings, the film thickness provided by the lubricant is sufficient to ensure surface separation, thus reducing energy losses due to contact.

- Heat Dissipation: The lubricating oil absorbs the heat and carries it away from critical components to maintain optimum operating temperature. This becomes especially vital in internal combustion engines, which can have temperatures even exceeding 300°F (150°C).

- Corrosion Protection: Usually, the lubricant contains anti-corrosive additives that create a protective film on the metal surface. This film keeps moisture and other corrosive elements from attacking the internal parts, especially in cases where humidity is high or corrosive chemicals are involved.

- Contaminant Removal: Basically, lubricating oil traps contaminants from metal particles, dirt, to combustion residues, which can cause abrasive damage or clog the system. The oils of high quality are designed to complement filtration systems that ensure cleanliness.

- Seal Enhancement: Some lubricants help seal gaps and imperfections in mechanical systems, improving efficiency and preventing leaks. For example, in hydraulic systems, lubricating oils improve seal integrity, thereby ensuring consistent pressure and flow.

These properties emphasize the indispensable role of lubricating oil as both a performance enhancer and a protective agent, contributing to the reliability and efficiency of machinery across diverse industrial applications. Proper selection and maintenance of lubricating oil are crucial for achieving these functions effectively.

Difference Between Lubricating Oil and Other Lubricants

These lubricating oils are liquids that freely flow and, therefore, are perfect for high-speed and high-temperature applications. Other lubricants like grease are semisolid and stay where they are put; therefore, they are better for sealing and intermittent uses.

|

Aspect |

Lubricating Oil |

Grease |

Solid Lubricant |

|---|---|---|---|

|

Form |

Liquid |

Semi-solid |

Solid |

|

Purpose |

High-speed, heat |

Sealing, bearings |

Hard-to-reach areas |

|

Heat Control |

Yes |

No |

No |

|

Protection |

Low resistance |

High resistance |

High resistance |

|

Frequency |

Frequent |

Rare |

Permanent |

|

Use Cases |

Engines, gears |

Bearings, seals |

Food, extreme temps |

The Importance of Lubricating Oil in Various Industries

Automotive Applications of Lubricating Oil

Lubricating oil is necessary for automotive systems to perform and last. It reduces wear, contributes to efficiency, and ensures smooth operation. There are five major automotive uses of lubricating oil:

- Engine Lubrication: From frictional forces between the moving parts in the engine and pistons and cylinders inside the engine, the lubricating oil keeps the wear to a minimum and ensures overheating does not set in. Nowadays, more advanced engine oils with additives are considered to give protection against thermal degradation, corrosion, and sludge formation, thus helping to extend the life of an engine.

- Transmission Systems: The transmission system in both automatic and manual forms employs abrasive transmission oils between the gears to reduce friction and help shift the gears from excessive heat build-up. These oils should be able to provide the best hydraulic properties to an automatic transmission so as to enhance the performance of the vehicle.

- Differentials and Axles: Gear oil is a type of lubricating oil that is used in differentials and axles to resist high-pressure sudden impacts and ensure proper operation of the gears under heavy loads. They are essential for vehicles that operate under high-torque or in off-road conditions.

- Hydraulic Systems: Power steering and all other hydraulic equipment in a vehicle use lubricating oil to transfer energy efficiently and guarantee smooth operation. Good quality hydraulic oils provide sufficient protection against wear, oxidation, and foaming, ensuring the reliability of such critical systems.

- Cooling and Heat Transfer: It cools by giving an escape route for the heat from crucial components in the engines or transmissions. Due to its having some specific properties, such as shear stability to viscosity, which remain stable at high temperature, it helps to remove heat from the hot surface, thereby preventing thermal degradation and failure of components.

These applications stand as a reminder of the technical nature of lubricating oils and emphasize their role in vehicle efficiency, reliability, and performance.

Manufacturing and Engineering Uses of Lubricating Oil

Lubricating oils are immensely important across various segments of manufacturing and engineering operations. It prevents friction and wear between mechanical components running in industrial plants, ensuring smooth and proper operation. They do so by laying down a thin film of oil on machine surfaces so that there is hardly any metal-to-metal contact between components, which then enhances equipment life and reliability. This ability is required in highly demanding conditions where equipment runs all the time under heavy load and high stress.

Then again, these oils are used in the fine machining processes. The lubricating oil acts as a lubricant and coolant to aid in the precision of cutting, grinding, and milling. Heat control in lubricating oil is essential to drain away heat generated by high-speed operations so that machining performance remains even, thus avoiding deformation or failure of components through overheating.

I think its significance in the manufacturing and engineering fields lies in enhancing productivity and reducing downtime. It supports efficient operations by keeping critical systems functioning and extends the lifespan of expensive machinery. Without it, industries would experience increased maintenance, higher energy consumption, and deteriorated quality of production processes. Therefore, lubricating oil is an essential commodity in striving for reliability and precision in engineering applications.

How Lubricating Oil Reduces Friction and Wear

The principal objective of a lubricating oil is to prevent friction and wear between two sliding surfaces by forming a thin protective film. The film lowers the coefficient of friction, allowing smooth sliding of the moving parts with the least resistance. The viscosity of the oil is the primary means to provide shear resistance, allowing consistent lubrication even at variable pressures and temperatures.

Recent developments in lubricating oil technology focus on incorporating various additives, such as anti-wear agents, friction modifiers, and detergents. Anti-wear agents such as zinc dialkyldithiophosphate (ZDDP) form a sacrificial layer over the metal surface, which greatly reduces wear. Friction modifiers allow frictional interactions to be optimized at the molecular level for better energy efficiency and reduced heat generation from friction. Detergents keep surfaces clean by dispersing contaminants and preventing deposit formation, which may hamper lubrication.

Temperature stability is yet another important feature associated with good-quality lubricating oils. Synthetic oils maintain viscosity effectively at both low and extremely high operating temperatures, thus facilitating efficient lubrication of equipment under an extensive array of conditions. Lubricating oils also serve to lessen friction and wear, thus protecting components and enhancing the longevity of industrial or mechanical systems and improving energy efficiency.

Types of Lubricating Oils and Their Properties

Mineral-Based Lubricating Oils

Mineral-based lubricating oils get their name from the process of refining crude oil, which makes them one of the most common types of lubricants in various applications. Oils are mainly made of varied hydrocarbon molecules, and properties may change depending on the refining process and quality of base stock. Mineral-based lubricating oils have excellent thermal stability and good lubrication properties at moderate working conditions.

When considered together, these mineral oils are grouped into three main categories depending on their refining operations: paraffinic, naphthenic, and aromatic. The paraffinic oils have a higher viscosity index and better oxidation stability, while in application, they are usually exposed to high temperatures. Naphthenic oils are, however, preferred in cases when low pour points and great solvency capability are paramount: for example, in transformer oils as well as some industrial applications. Less common are the aromatic oils, although they may be employed in cases in which their chemical nature is advantageous.

The ability of mineral-based lubricants to work effectively can indeed be tuned further by chemical additives. These additives provide stability against change in viscosity, resistance to oxidation, and anti-wear performance so that the oil may adequately live up to the stringent requirements modern machinery and industrial systems demand. Although synthetic options are taking the higher strata in the advanced applications, mineral-based lubricating oils continue to remain an affordable and assured solution in many standard operations.

Synthetic Lubricating Oils

Synthetic lubricating oils are made to give better performance properties than those derived from mineral sources. They are usually manufactured through chemical synthesis, thus creating uniform structures of molecules to increase thermal stability, more viscosity control, and much resistance to oxidation. Because of the precise engineering of the composition, they perform well in extreme temperature scenarios, both high and low, unlike mineral oils that may disintegrate or lose their ability to function.

Reduced friction and wear underneath high pressures are features of synthetic oil. Hence, due to their usage, the operational life of a machine increases. They come with built-in safety features and perform well in scenarios requiring high performance, such as in aviation, automotive engines, and industrial hydraulics, because of their low volatility and high flash points. More lately, the endeavor has been to develop synthetic lubricants with less environmental impact, those with biodegradable components yet not inferior in performance.

By going beyond regular standards of lubrication, synthetic oils allow machines to perform optimally under the rigors of modern industry, wherein, therefore, they have become major contributors to operational integrity and efficiency.

Bio-Based Lubricating Oils

These bio-based lubricating oils are obtained from agricultural sources through vegetable oil, animal fats, and other organic materials. These lubricants are very popular because they minimize serious environmental impacts, namely biodegradability, extremely low toxicity, and carbon footprint during production as well as disposal of the product. Bio-based oils have built-in strengths: higher lubricity, good viscosity-temperature profile, and higher load-carrying ability than mineral-based lubricants.

Now, new chemical engineering advancements have found means to modify and stabilize bio-based oils to contend against oxidative stability, thermal degradation, and hydrolytic resistance, which were some of the issues limiting their widespread acceptance. Reports imply that ester-based bio-lubricants can mimic or outperform conventional oils in high-temperature high-pressure situations and thus can be used as industrial lubricants, hydraulic fluids, and even interstate high-end auto machinery.

Thus, in all ways, the utilization of bio-based lubricating oils in industrial and commercial applications is a representation of sustainability and unfaltering performance or efficiency. They present an eco-friendly solution that also meets stringent regulations for promoting the circular economy.

Applications of Lubricating Oil

Lubricating Oil in Automotive Engines

Lubricating oil is essential for the very existence of a performing car engine. It is supposed to keep friction low against moving components, minimize abrasion, and, occasionally, guard against corrosion. Modern automotive oils are made with modern additives, such as detergents, antioxidants, and viscosity index improvers, to withstand harsh working conditions, such as high temperatures and pressure. These properties allow the oil to keep the engine performing optimally while also providing good fuel efficiency.

Some changes in recent times in synthetic or semi-synthetic engine oils have certainly improved their capacity for thermal stability and oxidation resistance over those of the conventional mineral oils. For example, the maximum working temperature for a synthetic lubricant is usually over 400°F, whereas under load conditions, mineral oil loses viscosity. Studies also reveal that high-performance lubricant oils can increase the oil change interval by as much as 50%, thus further reducing environmental wastage and maintenance costs.

Being a turbocharged and downsized type engine, lubrication demands are very high, requiring oil formulations that are fit for extreme conditions. Then, as the industry moves toward electrification and hybrids, lubricant research is being undertaken to meet the specialized requirements of electric powertrains, such as cooling and electrical insulation. The innovations are, therefore, paving the way for next-generation automotive lubricants to remain an indispensable component of both traditional motors and new electrified systems.

Use of Lubricating Oil in Industrial Machinery

Lubricating oil performs a paramount role in the efficient functioning and durability of industrial machinery. Among its foremost effects is friction reduction between moving components; in doing so, it prevents wear and tear. Lubricating oils lay down a shearing film, preventing direct metal-to-metal contact and thus prolonging machine life. Another use of the oils is cooling, as they transfer heat away from the areas of friction and keep them relatively cool. Lubricating oils also perform cleaning by removing contaminants such as grit, metal shavings, and sludge.

For extreme working conditions such as high temperature, heavy loading, and continuous working, modern industries require oils capable of lubrication. That is why synthetic lubricating oils are being used more and more for high-temperature machinery since they are prepared to exhibit better thermal stability and oxidation resistance. Other types of formulations include hydraulic oils for power transmission systems and gearbox oils for heavy-duty torque transmission.

According to the machinery specifications and industrial requirements should be better considered. In its optimal choice of lubricant, viscosity grade, load-carrying capacity, thermal stability, and seal compatibility should be considered. In addition, with the advancement of tribology, various specialized oils have been created for different types of equipment, thereby increasing efficiency while reducing downtime and maintenance costs for the industrial industry.

Benefits of Using Lubricating Oil for Equipment Longevity

- Reduction in Friction and Wear: Lubricating oils keep moving parts from coming into direct metal-to-metal contact, preventing friction and wear. It has been established that proper lubrication techniques can enhance up to 30% of an equipment’s life-cycle and thus reduce component replacement rates.

- Thermal Management: Lubricating oils act as a heat transfer medium and remove heat generated during the working process. Excellent lubricants allow a reduction of operating temperature by as much as 50°F, preventing thermal fatigue and preserving the structural integrity of the components.

- Protection From Corrosion: Quality lubricants generally contain anti-corrosion additives that develop a protective barrier against moisture and reacting chemicals. This protection prevents rust and chemical attack, which otherwise destroy the integrity of equipment over time.

- Increase Load-Bearing Capacity: Industrial-grade lubricating oils can perform under heavy pressure. This is very much applicable in industrial machinery, where there is always bearing stress.

- Maintenance Cost Reduction: Proper lubrication promotes long intervals between servicing by reducing wear and does away with premature failures. Industry studies prove that companies can reduce maintenance costs up to 25% if they specifically follow lubricant-lubrication programmes.

These benefits therefore demonstrate how important the role of lube oil is when it comes to maximizing operating efficiency, equipment longevity, and reducing overall expenses industrially.

Choosing the Right Lubricating Oil

Factors to Consider: Viscosity and Operating Conditions

Lubricating oil viscosity stands among the most important attributes to consider while choosing the right product for any industrial application. Viscosity describes the capacity of a fluid to resist its flow and thus directly confronts the capacity of machinery performance. Low viscosities of oils are suitable for components of high speed and light loads for reducing friction and making efficient energy transfer. Heavy load and slow movement are the default operating conditions for which oils of high viscosity are needed because the film strength should be enhanced thereon to prevent interaction of metal parts in direct contact by metal-to-metal. Association of viscosity grade to operating conditions by bearing their requirements is necessary for best lubrication and avoiding wear or damage of components.

The operating environment also plays an important role in the lubricating oil’s effectiveness. In the selection process, temperature, pressure, and contamination must be considered. Under high temperatures, the oils would be required to have a higher thermal stability and oxidation resistance so as to continue to provide good lubrication and avoid degradation. On the other hand, oils with a low pour point must be selected under severe cold environments to ensure that the lubricant remains fluid and provides proper lubrication at subzero temperatures. For equipment susceptible to contaminants such as water, dirt, or corrosive chemicals, it would be prudent to select oils with additives like dispersants, detergents, and rust inhibitors that address damage potential by these bodily contaminants.

Improper alignment of the viscosity characteristics with the operating conditions results in machinery failure even if maintenance is periodically undertaken. Hence, advanced processes for formulating lubricating oils exist with synthetic options exhibiting synthetic attributes suitable for diverse industrial needs, which are judged good enough to furnish them with almost any property for superior performance under normal or extreme conditions. Monitoring should always be executed: at one stage, measuring the viscosity index; at another, observing how the lubricant changes during use when exposed to both mechanical stress and temperature. When fully clear about these variables, large industries profit hugely from enhanced efficiency, very limited downtime, and equipment wellness.

Understanding Additives in Lubricant Oils

Additives are chemical compounds incorporated to improve the performance and longevity of lubricant oils so that machinery and components can operate under optimal conditions. These substances serve very particular functions, as limiting friction, wear, and corrosion, etc., and ensure the stability of oil against thermal, operational, and so on stresses. Some common types include anti-wear agents, detergents, dispersants, viscosity index improvers, and antioxidants.

Anti-wear additives, such as zinc dialkyldithiophosphates (ZDDP), form protective films to reduce metal-to-metal contact, thus prolonging the life of moving parts. Detergents and dispersants act synergistically against varnish, sludge, and deposit formation; hence, they keep the engine system clean even in high-temperature situations. Viscosity index improvers enable lubricants to maintain their effective viscosity through a wide operating temperature range, a highly useful property in machines operating within widely varying environmental conditions. Meanwhile, antioxidants slow down oxidation, which would otherwise cause the lubricant to thicken and shorten its useful life.

When formulated on an advanced level, the additives are further enabled by technologies such as nanotechnology and synthetic bases for energy efficiency and reliability. Lubricants whose additive packages are engineered for specific operational requirements ensure that engineers and equipment operators provide optimal working conditions with minimal maintenance expenditure and maximum equipment lifespan.

Frequently Asked Questions (FAQ)

Q: What is lubricating oil?

A: Lubricating oil is a vital substance used to reduce friction and wear between moving parts in machinery. It forms a protective fluid film that helps maintain the efficiency and longevity of engines and mechanical systems.

Q: What are the main components of lubricating oil?

A: The primary components of lubricating oil include base oil, which can be derived from crude oil or synthesized, and a variety of additives. These additives enhance properties like viscosity, corrosion protection, and anti-wear characteristics to ensure optimal performance under high temperatures.

Q: How does lubricating oil differ from hydraulic oil?

A: Lubricating oil is primarily used to lubricate moving parts and reduce friction, while hydraulic oil is used in hydraulic systems to transmit power. Both oils may have different viscosities and additives tailored for their specific applications.

Q: What role do additives play in lubricating oil?

A: Additives are used in lubricating oil to improve its performance. They can provide benefits such as oxidation resistance, corrosion protection, and enhanced lubricity. Common additives include extreme pressure additives that help protect against wear in high-stress conditions.

Q: Why is oil analysis important for lubricating oil?

A: Oil analysis is crucial for monitoring the condition of lubricating oil. It helps detect contamination, degradation, and wear particles, allowing for timely oil changes and maintenance to prevent machinery failure and extend the lifespan of equipment.

Q: Can lubricating oil be biodegradable?

A: Yes, there are biodegradable lubricating oils available, often made from renewable sources like vegetable oils. These bio-based oils are designed to provide effective lubrication while minimizing environmental impact.

Q: How does lubricating oil help in reducing wear and tear?

A: Lubricating oil works by forming a fluid film that separates moving parts, reducing friction and wear. This is particularly important in high-temperature and high-pressure applications, where proper lubrication can significantly extend the life of components.

Q: What is the significance of viscosity in lubricating oil?

A: Viscosity is a critical property of lubricating oil, indicating its resistance to flow. The right viscosity ensures that the oil can adequately lubricate components across a range of temperatures, maintaining optimal performance and preventing wear.

Q: What are the signs that lubricating oil needs to be changed?

A: Signs that lubricating oil needs to be changed include a noticeable change in color, a decrease in viscosity, the presence of contaminants, and the formation of sludge. Regular oil changes are essential to maintain machinery efficiency and reliability.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8