The Importance of Bearing Clearance in Machinery

Bearings are a critical component in countless machinery systems, enabling smooth rotational or linear movement while minimizing friction and wear. However, one often overlooked yet pivotal aspect of bearing performance is clearance—the small, precise gap that exists between bearing components. Proper bearing clearance isn’t just a matter of assembly; it directly influences operational efficiency, load distribution, heat generation, and the overall lifespan of machinery. This article will explore why bearing clearance is essential, how it impacts mechanical performance, and what engineers and technicians need to understand to ensure optimal functionality in their systems. Whether you’re designing complex industrial equipment or maintaining high-precision machines, understanding bearing clearance is key to unlocking durability and reliability.

What is bearing clearance, and why is it important?

Understanding bearing clearance

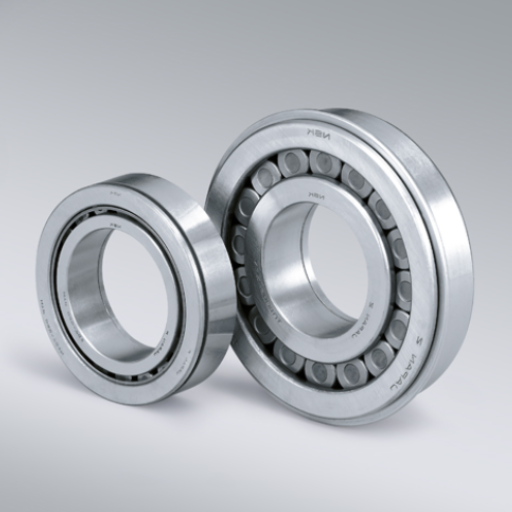

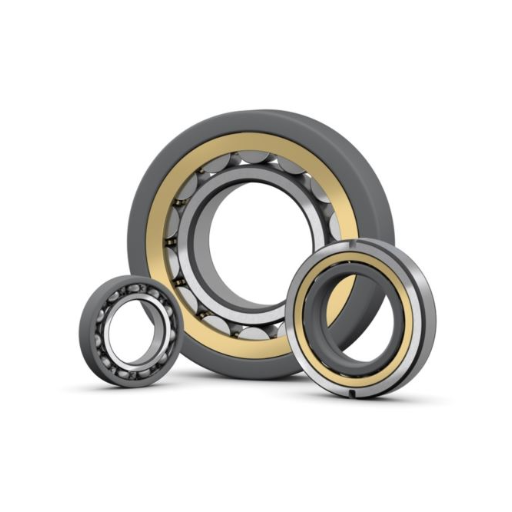

Bearing clearance pertains to the small space or gap that exists between the rolling elements (balls or rollers) and the raceways of the bearing. This clearance is essential for the free movement of the rolling elements to accommodate thermal expansion with little friction and smooth operation; with no clearance, the bearing may wear faster with increased heating, ultimately causing premature failure, which obstructs the machinery it supports.

Bearing clearance is essential because it directly influences load distribution, lubrication, and operational stability. If the clearance is less than stipulated or interferes, the bearing experiences an extreme multiplier of contact pressure generated by larger heat and the breaking of lubricant. Too much clearance results in vibration and noise coupled with uneven load distribution that reduces the accuracy of the machine or the system. The optimum performance is attained when the maximum clearance recommended by manufacturers, vis-à-vis application and operating environment, is adhered to.

To select the right bearing clearance, engineers or technicians generally consider some factors such as bearing type, load, conditions of operation, speed, and temperature. Usually, the articulated radial and axial clearances are given in technical literature by manufacturers. It is, therefore, a practice to monitor the condition, plus proper installation of the bearing and adjustment of either preload or clearance to maintain satisfactory service life and reliability of the bearing and system, respectively.

The role of bearing clearance in reducing friction

In the realm of mechanical systems abreast with various components of metals, bearing clearance is of utmost importance in minimizing friction, accordingly ensuring proper operating lubrication and accommodating thermal expansion during operation. This clearance ought to be sufficient to allow an effective lubricant film between the surfaces of the bearer; this film acts as a preventer against direct metal-to-metal contact, thus causing less friction and wear. A lack of clearance, therefore, would lead to heat buildup-perhaps even premature failure.

On the other hand, clearance becomes necessary to offset any variations in dimensions due to changes in temperature or adverse load conditions. For instance, at a high operating temperature, bearing components could expand, and if the clearance is too tight, friction will rise to an extent where the shaft’s rotation is hindered. If, on the contrary, it is unnecessarily large, there would be vibration and instability, uneven load distribution, degradation of performance, and the life of components. Hence, an optimal clearance level should be maintained to balance between these factors to ensure smooth operation.

Manufacturers and engineers arrive at the required clearance for a particular application through precise calculation and recommendations. Bearing type (ball, roller, or sleeve), speed, nature of load, and environmental conditions are among the factors considered in choosing the correct clearance. Following these specifications improves the reliability of the system, makes it energy efficient by minimizing energy loss to friction, and prolongs the life of machinery. Good clearance management epitomizes the balance between mechanical design and maintenance.

How bearing clearance affects machinery performance

Bearing clearance is a very important aspect that directly relates to securing machinery performance and life by affecting load distribution, friction, and temperature of operation. If clearance is too tight, friction increases excessively, causing heating and wear of bearing parts. On the other hand, a large clearance introduces vibration, causing misalignment and compromised load-carrying ability, thereby reducing efficiency and the life of the machine.

Ideal clearance will ensure the lubricating film functions effectively, minimizing direct metal-to-metal contact and all frictional losses. This creates a stable operating condition so that rotational speeds remain consistent and operating temperatures are safe. The clearance needs to absorb thermal expansion during the operation to keep stress from building up inside the machinery, thereby reducing the possibility of failure of the components themselves.

The organization has a direct increase in reliability and operational efficiency when proper bearing clearances are considered while designing or servicing machinery. Industry standards dictate acceptable clearance ranges based on application requirements, such as those issued by ISO or ANSI. It continues to be ensured that the mechanical system performs at its peak under changing operational conditions by monitoring the bearing clearance and readjusting it in scheduled maintenance intervals.

How does oil viscosity impact bearing clearance?

The relationship between oil viscosity and oil film thickness

Oil viscosity determines the optical thickness of the oil film being deposited between bearing surfaces. In an ideal condition with adequate viscosity, the lubricant keeps the metal surfaces apart, thereby preventing friction and wear due to direct contact. Viscosity is directly proportional to the thickness of the oil film; the greater the viscosity, the thicker the oil film, and hence the higher will be the oil film’s ability to carry a load. However, bearing oils with excessively high viscosity may produce high hydrodynamic drag and corresponding energy loss, heat generation, and potential decline in system efficiency. Thus, the utmost attention should be paid to the selection of the viscosity grade to keep a balance between protection and performance.

The fluid-dynamics principles govern the formation of the oil film, especially under hydrodynamic lubrication conditions. Viscosity is directly proportional to resistance to flow within the film; thus, thicker films form under higher-viscosity conditions, especially at lower shear rates. Still, as speed becomes high enough, a film may become sustained by the dynamic pressure effects, albeit from the lower-viscosity oil, thereby emphasizing the fact that viscosity and operating conditions must be considered simultaneously during lubricant selection.

Temperature changes affect oil viscosity and, consequently, oil film thickness. With an increase in temperature, viscosity reduces, thereby producing thinner protective films if the viscosity-temperature behavior of the lubricant is inadequate. Present lubricant formulation practices usually incorporate viscosity index improvers to counter such effects so that the films may be formed quite stably over a wide thermal range. With the advent of synthetic oil technology, it became possible to control viscosity-temperature behavior quite precisely for a given application so that the lubricant always shows a stable performance even in severe applications. The life of a bearing system can be substantially improved, and system reliability enhanced by the correct monitoring and adjustment of viscosity on the basis of real-time operational data.

Effects of thicker oil on bearing clearance

It is to be stated here that the oil viscosity in a bearing system may exhibit significant and measurable impacts on clearance, operating efficiency, and component life.

- Reduced Bearing Clearance: Thick oil increases the lubrication film thickness and could reduce the effective clearance, while increasing load-carrying capacity; decreased tolerance for thermal expansion or misalignment will likewise increase operating temperature.

- Reduced Start-Up Efficiency: These high-temperature oils require a great deal of force to set the starting movement, resulting in more power being consumed during the start-up. Being thicker, resistance to flow is increased as one enters the low-temperature region, thus delaying the start or exerting undue strains on the system.

- Better Damping: Thick oils work better on damping as they resist rapid bearing movements, which in turn stabilizes the system in high-speed-high-vibration applications. Such an advantage is appreciated by the precision machinery, but at the cost of a slight restriction on responsiveness.

- Higher Lubricant Shear Stress: Thicker oil means higher shear stresses in the lubricant; therefore, higher energy dissipation as heat. This would speed up lubricant degradation and thus calls for more frequent oil changes or an advanced temperature control strategy.

- Over-Lubrication: Increased viscosity makes the high chances of over-lubrication, which causes unnecessary drag in the system. Over-lubrication leads to oil churning that reduces efficiency and also promotes the formation of air bubbles, which un-lubricate the bearings.

That said, it is obvious that stemming from the balancing of oil viscosity against system needs is paramount for efficient bearing operation and bearing reliability.

Why thinner oils can lead to looser clearances

Lower-grade, thinner oils possess much less resistance to flow vis-à-vis their thicker counterparts. This somewhat lower viscosity may result in a thinner hydrodynamic film between bearings or other components moved by the machine. An insufficiently thick oil film allows metal-to-metal contact, increasing damage to the surfaces and accelerating the growth of clearances with time.

In order to overcome limited film strength and provide separation of surfaces, many mechanical engineers optimize system tolerances or add additives to the thinner oils to increase their load-carrying properties. However, given longer use, abrasion due to poor lubrication and thermal stresses causes dimensional changes in specimens, thereby increasing clearances.

Latest studies also suggest that under severe operating conditions, such as thin oil in high-speed rotating machinery or at elevated temperatures, a decline in thermal stability of the thinner oil speeds up clearance growth. Thus, because the correct choice of oil viscosity should be based on operational demands and mechanical design tolerances, it is necessary to prevent premature degradation or wear.

What is the rule of thumb for determining bearing clearance?

Using journal diameter to calculate bearing clearance

Bearing clearance is primarily determined by the journal diameter since lubrication and mechanical function are highly dependent on this factor. As a general rule of thumb, usually clearances are allowed to vary between 0.001 and 0.0015 inches per inch of the diameter of the journal. A 2-inch-diameter journal normally has a clearance between 0.002 and 0.003 inches. This allowance gives room for thermal expansion, considerations of lubricant film thickness, and changes in operating conditions.

Nevertheless, modern technology has added a new dimension to these age-old practices, aided further by data analytics opportunities. Manufacturers and engineers use computational simulations, alongside advanced studies of materials, to arrive at clearance values likely to be optimal for a given load capacity, rotational speed, operating temperature, and lubricant viscosity. For instance, tighter clearances could be used to improve stability in high-speed applications, whereas machinery subjected to heavy load conditions might need relatively larger clearances to account for shaft deflections.

It is imperative to cross-check these recommendations with manufacturer-specific recommendations and employ precise measuring instruments such as micrometers and bore gauges to ascertain precise clearances during installation and maintenance procedures. When erecting bearing systems in consonance with good practices, bearing system life can be substantially increased, thereby ensuring reliability.

The significance of the 0.001-inch rule of thumb

One widely accepted engineering and machining principle emphasizes that accuracy is sacrosanct for tolerance and clearance computations. The 0.001-inch rule means that a clearance of 0.001 inches should be maintained for every inch of shaft diameter as a rough mark. The need for exactness reflects the paramount priority for smooth functioning and operational reliability of systems.

The 0.001-inch rule-of-thumb is especially important when working with rotating machinery. For example, if the clearance isn’t sufficient, friction will crash on an overloaded basis, causing problems such as overheating, accelerated wear, and premature failure of components on the downside. Too much clearance can, on the other hand, interfere with alignment or produce vibrations that seriously impair efficiency.

With more recent developments in technology and analytics, the 0.001-inch rule enjoys well-earned validation as an exact working minimum. Research supports that the minimum misalignment conforming to these tolerances will reduce energy loss and downtime through mechanical failure. By embracing this rule in conjunction with today’s analytical tools, from the domain of precision metrology to the working professional, can line up and tweak tolerances with pinpoint accuracy-locally to internationally as to give even the most demanding work envelopes a clean engineering finish.

Adjusting bearing clearance for optimal performance

The proper adjustment of bearing clearance is a vital consideration in ensuring that the machinery is reliable and efficient. Bearing clearance is also called internal clearance. It pertains to the very small gap between the rolling elements and the raceways in a bearing. It is this clearance that directly affects the bearing’s ability to take loads, reduce friction, and dissipate heat. Bearing clearance cannot be improperly adjusted, or else the bearing will tend to have better wear, generate more heat, and shorten the operational life span. Clearance must be selected with due consideration to the application itself, the operating condition be specific, speed, and load-as well as to how much the bearing components themselves will expand as a result of any appreciable change in temperature.

It involves measuring the dimensions of the bearing and then taking into consideration whether the bearing will be subjected to a radial load, an axial load, or a combined load, since each of these states of loading demands a different approach to bearing adjustment. For example, radial clearance typically is the greatest concern for shafts requiring rotational precision; axial clearance would be crucial where thrust loads dominate the application. Dynamic simulation software, precision measuring instruments, and the like are all valuable tools in arriving at an equation for the optimum clearance. At the same time, the lubricant chosen for the bearing is important since it directly affects the coefficient of friction and, under conditions of either high speed or high temperatures, may influence the actual effective operating clearance.

In general, with a slight reduction of internal clearance, it shows an improvement in the rolling contact behavior under very high loads. While internal clearance decreases a lot, the stress concentration on these areas will increase, and there is a high risk of lubricant film failure. On the other hand, loose tolerances on internal clearance may result in vibration and misalignment of rotating machinery. The capability to adjust the clearance dynamically, thus keeping the bearing continuously at optimum efficiency and minimal downtime, is realized by integrating conventional adjustment methods with recent innovations, such as real-time performance monitoring and adaptive control systems. Thus, a great plan and ample testing in real-life scenarios constitute the two-legged stool to achieving adjustment in balance with design tolerances and long-term operational goals.

What is the difference between loose vs tight bearing clearances?

Benefits and drawbacks of loose clearances

- Benefits of Loose Clearances

- Improved Lubrication Flow: With loose bearing clearances, a greater volume of lubricant is provided the opportunity to circulate through the components. Hence, more heat is dissipated, reducing the localized overheating effects, for example, under high-speed or load conditions.

- Tolerance for Thermal Expansion: Bearings with loose clearance tend to compensate better for thermal expansion of components, therefore making them favourable in applications where wide temperature variation is expected.

- Reduced Risk of Seizure: Loose clearance offers adequate space in between bearing surfaces to reduce the probability of seizure caused by contamination or slight misalignment during operation.

- Extended Component Compatibility: Looser clearance accommodates minor imperfections of manufacturing and assembly, thus making them more adaptable and easier to work with among different machinery types or designs.

- Resistance to Vibration Stress: Machines subjected to high levels of vibrations, or subjected to shock loads, benefit from loose clearances, which ensure absorbing the impact without impeding bearing operation.

- Drawbacks of Loose Clearances

- Decreased Load Capacity: Loose clearances reduce the distribution of the load, thus reducing the maximum capacity of the bearing load compared to tighter ones.

- Higher Operational Noise: This greater distance between bearing surfaces is the excellent cause for vibrations to develop, resulting in undesirable noise, especially in applications concerned with noise and precision.

- Reduced Rotational Accuracy: Loose clearances cause slight misalignments and are hence an impediment to any applications where high rotational accuracy is required.

- Accelerated Wear Under Light Loads: Depending on load magnitude and load consistency, loose clearances could cause uneven wear patterns, thereby decreasing overall bearing life.

- Potential Lubricant Leakage: More clearance gaps would result in an increase in lubricant leakage rates, which might require frequent maintenance to maintain the optimum level of lubrication.

Advantages of tighter clearances in specific applications

- Rotational Precision Enhancement

Tighter clearances lower the chance of shaft misalignment, ensuring maximum rotational precision. This factor is critical in machines that require extreme precision, such as CNC machines, where discrepancies in micrometers render the output inaccurate.

- Improved Load Distribution

Tighter clearances curb internal movements and allow for the distribution of load across bearing surfaces more evenly. Having a lesser localized stress concentration than a well-sealed bearing increases its life by 15-20%, and uplift in fatigue life is exhibited under tightly controlled conditions.

- Reduced Vibrations and Noise

Due to less internal play, machines operating with tight clearances vibrate and generate noise to a considerably minimal level. For instance, in aerospace applications, noise reduction beyond 30 percent benefits precision bearings in enhancing overall system stability and safety.

- Greater Risk of Lubricant Shear or Leakage

The smaller the clearance, the better the lubricant retention, thus leakage is reduced. This results in uninterrupted lubrication and performance, cutting down on maintenance. Industrial test data show lubricant consumption declines as much as 25% in systems with optimized tight clearances.

- Greater Thermal Stability

Tight clearance restrains any excessive expansion caused by heat, as controlled fit handles the dimension changes of the workpiece induced by temperature. It, therefore, makes the operations more stable in high-heat environments, such as turbochargers and industrial furnaces.

How thermal expansion affects bearing clearance

The thermally induced increase in bearing clearances occurs as metals expand with increasing temperature. This phenomenon affects permissible clearances in bearing assemblies and gives rise to some adverse effects, including operational inefficiencies and component failure. As thermal expansion reduces the internal clearance in a bearing and thereby increases contact pressure, it also increases friction against rolling elements and raceway wear. On the other hand, increased clearance affects load distribution and causes the bearing to lose capacity in maintaining alignment and load.

As an example, steel, which is extensively used for bearing components, has a coefficient of linear thermal expansion of about 11–13 × 10^-6/°C. Increases of about 50°C would bring in a change in dimensions of about 0.55–0.65 mm per meter in any steel bearing. Such effects of thermal expansion are highly detrimental in high-temperature applications like industrial furnaces or combustion engines, where components undergo fast thermal cycles.

The effectiveness of thermal expansion control involves choosing materials with matching thermal expansion coefficients, using super heat-resistant alloys, or even with settings that have been pre-engineered, such as reduced initial clearance. On the other hand, with the use of predictive models through finite element analysis (FEA), engineers can simulate thermal behavior and optimize bearing design for particular applications.

How do you ensure the right bearing clearance in engine building?

Using a micrometer to measure bearing clearance

To ensure exact clearance measurement during engine building, the micrometer cannot be beat for accuracy if the mechanism, working technique, and calibration practices concur. The usual procedure begins with measuring the diameter of the crankshaft journal. Place the micrometer around the journal with no loose grip or tilt, then take the reading to the nearest thousandth of an inch or hundredth of a millimeter according to the scale of the micrometer.

Next, use a dial bore gauge to measure the inside diameter of the installed bearing shell in the engine block or connecting rod. Calibration of the bore gauge to the reference point provided by the micrometer’s journal reading is essential before accepting any reading. Enter the bore gauge into the bearing shell and carefully measure at several points or positions in axial and radial directions to sense inconsistencies, in maybe tapering.

Clearance is determined by subtracting the crankshaft journal diameter from the inner diameter of the bearing. Target values of clearance depend on the type and application of engines; for performance-type engines, tighter clearances are required to maintain the integrity of the oil film. These clearances are usually specified by the manufacturers and should be within the tolerance details given in technical manuals. Careful measurement and maintenance of the tools can reduce possible errors, thus assuring engine reliability.

The role of engine builders in ensuring performance and longevity

Engine builders harbor the engine’s ultimate thrust toward becoming either a dream machine or a nightmare in timely completion. The precise assembly, fine-tuning, and quality control conducted by them make for engines that can work efficiently under varied conditions. Here are some of the five key responsibilities and practices of engine builders that emphasize their role in this process:

- Precision Machining and Assembly: Using precision machines, the builder has to maintain the tolerances in the process of finishing surface irregularities in the cylinder walls, crankshafts, and piston rings. Correct tolerances ensure greater sealing, less frictional loss, hence an efficient engine.

- Component Compatibility and Material Selection: Selection of materials and components depends upon how an engine will be adapted to an operational manual. For example, performance engines might require forged pistons and hardened crankshafts to handle heavy torque and RPMs; standard engines would consider cost and durability.

- Balancing and Blueprinting: Fitting and balancing mean making sure that all engine components meet strict specifications and are balanced to reduce vibrations for enhanced operational stability. Balancing reduces wear and tear on components, while blueprinting enhances power output by increasing volumetric efficiency.

- Heat Management and Cooling Optimization: A good engine cooling solution helps create the right conditions for oil flow, coolant circulation, and thermal dissipation to prevent overheating of components and thus ensure longer life. Builders fit such thermal management systems along with their high-performance radiators when necessary.

- Validation and Testing: Builders use stringent testing regimes, including dyno tests, to establish an engine’s performance about horsepower, torque, fuel economy, etc., before its installation. This testing data is used to ferret out weak points and to assert the engine’s ability to perform satisfactorily under defined conditions.

Creating the above thereby increases the immediate performance of engines, extends their service life, and mitigates likely premature failures or expensive repairs.

Frequently Asked Questions (FAQ)

Q: What is bearing clearance, and why is it important in machinery?

A: Bearing clearance refers to the small space between the bearing surfaces and the rotating shaft or journal. It is crucial because it allows for the formation of an oil wedge, which provides a protective lubrication layer, preventing metal-to-metal contact. Proper clearance is essential for engine performance and the longevity of machinery.

Q: How does bearing clearance affect engine performance?

A: Bearing clearance affects engine performance by influencing oil flow and pressure. Too little clearance can increase resistance and lead to inadequate lubrication, while too much clearance can result in lower oil pressure and inefficient oil pressure distribution, potentially causing damage to engine bearings.

Q: What is the role of the oil wedge in bearing clearance?

A: The oil wedge is crucial in bearing clearance as it forms a film of oil that separates the bearing surfaces from the rotating shaft. This film minimizes friction and wear, ensuring the engine operates smoothly and efficiently. An ideal oil wedge is necessary to maintain bearing performance and prevent damage.

Q: How does oil temperature affect bearing clearance?

A: Oil temperature can significantly impact bearing clearance. Higher temperatures can thin the engine oil, reducing its viscosity and potentially compromising the oil wedge, while lower temperatures can thicken the oil, increasing flow resistance. Maintaining the optimal oil temperature is key to ensuring the right clearance and efficient engine operation.

Q: What happens if bearing clearance is too tight or too loose?

A: If bearing clearance is too tight, it can lead to increased friction, higher temperatures, and potential bearing failure due to inadequate lubrication. Conversely, if the clearance is too loose, it may cause lower oil pressure and insufficient lubrication, leading to wear and decreased engine performance.

Q: How do you determine the correct bearing clearance when building an engine?

A: Determining the correct bearing clearance when building an engine involves relying on empirical data and evidence-based practices. This includes considering factors such as the type of bearings (e.g., roller bearings, ball bearings), engine specifications (e.g., 350 small-block), and using standard bearings or slightly larger ones for specific applications.

Q: What are the differences between main bearing and rod bearing clearances?

A: Main bearing and rod bearing clearances differ in their specific functions and the loads they handle. Main bearings support the crankshaft’s rotation, requiring precise clearance to handle the engine’s overall load. Rod bearings connect the pistons to the crankshaft, needing clearance that accommodates the angular contact and dynamic movement.

Q: Why is maintaining the optimal bearing clearance critical in machinery?

A: Maintaining the optimal bearing clearance is critical because it ensures that bearings play a vital role in reducing friction, preventing metal-to-metal contact, and providing smooth operation. Proper clearance helps in clutch bearings and other components function effectively, thus improving overall machinery efficiency.

Q: How does journal diameter affect bearing clearance?

A: Journal diameter affects bearing clearance, as every inch of journal diameter requires precise clearance to ensure the formation of the oil wedge. Larger diameters may require slightly larger clearances to accommodate the increased surface area and maintain effective lubrication.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8