The Advantages of Thrust Cylindrical Roller Bearings in European Industries

1 Introduction

In the world of industrial machinery and mechanical engineering, one critical component that plays a pivotal role in ensuring the smooth operation of various systems is the thrust cylindrical roller bearing. These bearings, with their unique design and capabilities, hold immense significance in numerous industrial applications.

Thrust cylindrical roller bearings, often referred to as simply “thrust bearings,” are a type of rolling-element bearing designed to handle axial loads, providing essential support and control in machinery that involves linear motion or the transmission of thrust forces. Their cylindrical rollers are arranged in a specific pattern, allowing them to accommodate high axial loads while maintaining precise alignment.

European industries, known for their commitment to precision, efficiency, and innovation, have long recognized the value of thrust cylindrical roller bearings in enhancing the performance and reliability of their machinery. In this article, we will explore the key features and advantages of these bearings, their applications in various European industries, and the benefits they bring to manufacturers across the continent.

2 Key Features of Thrust Cylindrical Roller Bearings

Thrust cylindrical roller bearings, often known simply as thrust bearings, are remarkable engineering marvels that find their application in a wide array of industries, especially in Europe where precision and efficiency are paramount. To understand why they hold such a pivotal role in European industries, it’s essential to delve into their key features and design.

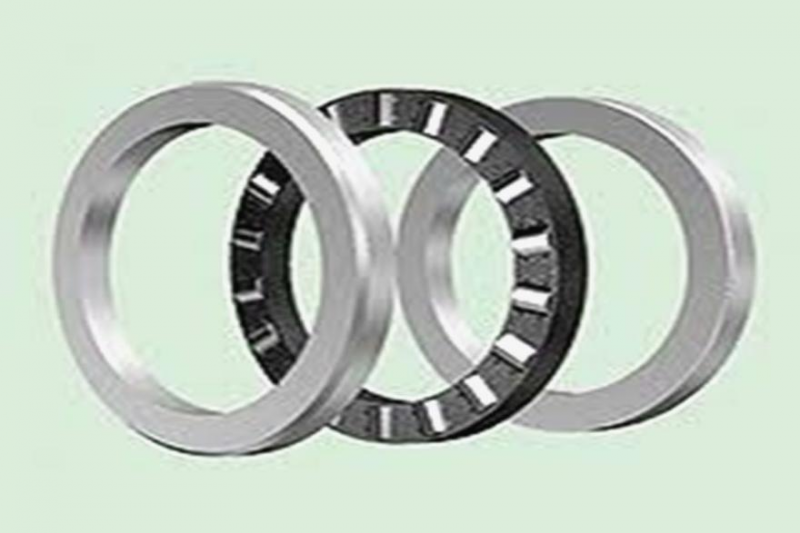

Structural Components and Design

Thrust cylindrical roller bearings are meticulously designed to handle axial loads and provide exceptional support in scenarios involving linear motion or the transmission of thrust forces. They consist of several key components, each playing a vital role in their performance.

Cylindrical Rollers

The most distinctive feature of these bearings is their cylindrical rollers. These rollers are arranged in a specific pattern within the bearing, allowing them to efficiently distribute axial loads. The cylindrical shape provides increased contact area, which, in turn, results in higher load-carrying capacity.

Raceways

Thrust bearings consist of two raceways – the shaft washer and the housing washer. These raceways guide the rollers, ensuring they move smoothly and accurately. The raceways are precisely machined to minimize friction and reduce wear over time.

Cage

A cage or separator holds the cylindrical rollers in position and prevents them from coming into direct contact with each other. This design not only maintains proper spacing but also reduces friction and heat generation, contributing to the bearing’s durability.

Load-Bearing Capacity and Axial Load Handling

One of the primary advantages of thrust cylindrical roller bearings is their exceptional load-bearing capacity, making them suitable for heavy-duty applications. These bearings excel in handling axial loads, whether they are thrust forces or linear movements. Their ability to withstand high loads while maintaining stable operation is crucial in many European industries, such as manufacturing, aerospace, and automotive.

Precision and Durability

Precision engineering is at the heart of European industries, and thrust cylindrical roller bearings align perfectly with this ethos. Their design allows for precise control of axial movements, ensuring that machinery operates with minimal play or deviation from the desired path. This precision is vital in applications where accuracy is non-negotiable, like robotics, machine tools, and industrial automation.

Furthermore, the durability of thrust cylindrical roller bearings is a significant asset. European manufacturers appreciate the extended service life these bearings offer, reducing downtime and maintenance costs. This longevity is achieved through meticulous material selection, heat treatment, and quality control during the manufacturing process.

In conclusion, thrust cylindrical roller bearings possess a unique combination of features that make them indispensable in European industries. Their structural design, load-bearing capacity, precision, and durability contribute to improved performance and efficiency in various applications. As we explore their applications in European industries in the subsequent sections, it becomes evident why they are the preferred choice for many manufacturers in the region.

3 Applications in European Industries

Thrust cylindrical roller bearings have established themselves as essential components in a multitude of European industries, offering superior performance and reliability. In this section, we will explore some prominent industries across Europe where these bearings find extensive use and delve into the ways in which they contribute to enhanced efficiency and overall performance.

| Automotive Industry | The European automotive sector, renowned for its innovation and commitment to producing high-quality vehicles, heavily relies on thrust cylindrical roller bearings. These bearings are prominently featured in the drivetrains of vehicles, particularly in transmissions and wheel hubs. Their precise axial load-handling capabilities ensure smooth gear shifting and reduced friction, ultimately leading to improved fuel efficiency and enhanced driving experiences. |

| Aerospace and Defense | In the aerospace and defense sector, where precision and reliability are non-negotiable, thrust cylindrical roller bearings are chosen for various critical applications. They are used in aircraft landing gear systems, missile guidance mechanisms, and radar systems. These bearings guarantee the accurate control of axial loads, ensuring the safety and functionality of aerospace equipment. |

| Manufacturing and Industrial Machinery | Manufacturing industries in Europe benefit significantly from the advantages offered by thrust cylindrical roller bearings. These bearings are extensively employed in industrial machinery, such as CNC machines, robotics, and conveyor systems. Their ability to handle heavy axial loads with minimal deflection ensures consistent and precise manufacturing processes. |

| Renewable Energy | As Europe makes substantial strides towards sustainable and green energy solutions, thrust cylindrical roller bearings have found their place in the renewable energy sector. Wind turbine generators and solar tracking systems utilize these bearings to efficiently transmit thrust loads and facilitate the precise positioning of components. |

In conclusion, thrust cylindrical roller bearings are instrumental in various European industries, playing a vital role in enhancing efficiency, precision, and performance. Their applications in automotive, aerospace, manufacturing, and renewable energy sectors, along with real-world case studies, emphasize their indispensable nature and how they continue to drive innovation and progress across Europe.

4 Benefits for European Manufacturers

Thrust cylindrical roller bearings offer a multitude of benefits to European manufacturers, making them a preferred choice in various industries across the continent. .

Enhanced Productivity

One of the foremost advantages of thrust cylindrical roller bearings is their ability to enhance productivity in manufacturing processes. Their precision engineering and load-handling capacity allow machinery to operate with minimal downtime and reduced interruptions. European manufacturers rely on this reliability to maintain consistent production levels.

These bearings are particularly beneficial in high-speed applications, such as CNC machining and automated assembly lines. Their ability to handle axial loads efficiently ensures that machinery operates at peak performance, resulting in faster production cycles and increased output.

Cost-Effectiveness and Reduced Maintenance

In the competitive landscape of European industries, cost-effectiveness is crucial for manufacturers. Thrust cylindrical roller bearings contribute to cost savings in various ways. Their durability and ability to withstand heavy loads mean they require less frequent replacement. This results in reduced maintenance costs and less downtime for machinery over time.

Furthermore, the precision design of these bearings minimizes wear and tear on associated components, such as shafts and housings. This extends the lifespan of the entire system, reducing the need for costly repairs or replacements.

Contribution to Sustainable Manufacturing

In an era of growing environmental awareness, European manufacturers are actively seeking ways to reduce their ecological footprint. Thrust cylindrical roller bearings play a role in achieving sustainability goals. Their efficiency in transferring axial loads results in reduced energy consumption, contributing to lower carbon emissions.

Moreover, the extended service life of these bearings means fewer replacements and less waste generated from discarded components. European manufacturers can align their operations with sustainable practices while benefiting from the economic advantages of using thrust cylindrical roller bearings.

In summary, thrust cylindrical roller bearings offer European manufacturers a trifecta of advantages: enhanced productivity, cost-effectiveness, and sustainability. Their precision engineering and ability to withstand heavy axial loads ensure smooth and efficient manufacturing processes while simultaneously contributing to the long-term economic and environmental sustainability of the European manufacturing sector.

5 Comparison with Other Bearing Types

Thrust cylindrical roller bearings stand out as versatile components in the realm of industrial machinery. To truly understand their advantages in European industries, it’s essential to compare them with other types of bearings and appreciate the unique features that make them the preferred choice in this region.

Comparing Thrust Cylindrical Roller Bearings

Thrust Ball Bearings

Thrust ball bearings are a common alternative to thrust cylindrical roller bearings. While they also handle axial loads, they do so differently. Thrust ball bearings utilize balls rather than cylindrical rollers. The key difference lies in the contact area – cylindrical rollers have a larger surface area, which allows for better load distribution. This characteristic is crucial in European industries that prioritize precision.

Advantage of Thrust Cylindrical Roller Bearings: The larger contact area of cylindrical rollers provides better load-carrying capacity and reduces the risk of surface damage, making them suitable for applications where precision is paramount, such as manufacturing and automation.

Tapered Roller Bearings

Tapered roller bearings are often used for radial loads, where the load is applied perpendicular to the shaft. While they can handle some axial loads, their primary function is to support radial forces. In contrast, thrust cylindrical roller bearings are specifically designed to handle axial loads, making them more suitable for applications involving thrust forces or linear motion.

Advantage of Thrust Cylindrical Roller Bearings: Thrust cylindrical roller bearings excel in situations where axial loads dominate. Their optimized design ensures stable and precise operation, a critical requirement in European industries like aerospace and automotive.

Spherical Roller Thrust Bearings

Spherical roller thrust bearings, as the name suggests, can handle both axial and radial loads. They have a more complex design compared to thrust cylindrical roller bearings, with spherical-shaped rollers. While they offer versatility, this complexity can lead to increased friction and heat generation.

Advantage of Thrust Cylindrical Roller Bearings: In European industries where efficiency and longevity are priorities, thrust cylindrical roller bearings have the upper hand. Their straightforward design minimizes friction, resulting in improved performance and reduced maintenance costs over time.

Advantages for European Industrial Settings

In European industrial settings, the choice of bearings is influenced by factors such as precision, efficiency, and longevity. Thrust cylindrical roller bearings align perfectly with these requirements, making them the preferred option. Here are the key advantages that make them stand out:

| Precision | European industries demand precision in machinery operation. Thrust cylindrical roller bearings, with their large contact area and ability to handle axial loads with minimal deflection, ensure that machinery operates with precision, reducing errors and enhancing product quality. |

| Efficiency | These bearings excel in high-speed applications, where their load-carrying capacity and reduced friction result in smoother and more efficient machinery operation. In industries like manufacturing and automation, efficiency directly impacts productivity. |

| Longevity | European manufacturers appreciate the durability of thrust cylindrical roller bearings. Their ability to withstand heavy axial loads without premature wear reduces the need for frequent replacements, leading to cost savings and reduced downtime. |

Limitations and Alternative Scenarios

While thrust cylindrical roller bearings offer numerous advantages, it’s essential to acknowledge their limitations. They may not be the optimal choice in scenarios where radial loads dominate or where space constraints limit their use. In such cases, alternative bearing types like radial ball bearings or spherical roller bearings may be more suitable.

In conclusion, thrust cylindrical roller bearings shine in European industrial settings due to their precision, efficiency, and longevity. Their distinct advantages over other bearing types align with the stringent requirements of industries across Europe, making them the top choice for manufacturers prioritizing performance and reliability.

6 Conclusion

In the fast-paced world of European industries, where precision, efficiency, and sustainability are paramount, thrust cylindrical roller bearings have proven themselves as indispensable assets. Throughout this article, we have explored their key advantages and applications, shedding light on why these bearings are the preferred choice in various sectors. As we conclude, let’s recap the essential takeaways and emphasize their significance in driving efficient and reliable machinery across Europe.

Thrust cylindrical roller bearings, with their meticulous design and structural excellence, offer European industries several key advantages. Their ability to handle axial loads with precision and durability ensures that machinery operates smoothly and consistently. This precision is crucial in industries where even the slightest deviation can lead to errors and inefficiencies.

Moreover, these bearings contribute to enhanced productivity by minimizing downtime and reducing maintenance costs. European manufacturers appreciate the cost-effectiveness and long-term savings associated with the adoption of thrust cylindrical roller bearings. Their robust design and extended service life mean fewer replacements, translating to significant economic benefits.

Additionally, as European industries increasingly prioritize sustainability, these bearings play a crucial role. Their efficient load-handling capabilities lead to reduced energy consumption, aligning with the continent’s commitment to eco-friendly manufacturing practices. Furthermore, their durability and reduced need for replacements contribute to waste reduction, furthering the sustainability agenda.

In conclusion, thrust cylindrical roller bearings are not just components but enablers of progress in European industries. Their precision, efficiency, longevity, and eco-friendliness make them the ideal choice for manufacturers looking to stay ahead in the competitive landscape. As we move forward, it is essential to encourage the continued adoption of these bearings, as they hold the key to driving industrial growth, innovation, and sustainability across Europe. By embracing the advantages they offer, European industries can maintain their position at the forefront of precision engineering and manufacturing excellence.

7 FAQs: Common Questions about Thrust Cylindrical Roller Bearings

As we conclude our exploration of the advantages of thrust cylindrical roller bearings in European industries, it’s essential to address some common questions that often arise regarding these critical components. This section aims to provide clarity and further insight into the world of thrust cylindrical roller bearings.

1. What are thrust cylindrical roller bearings, and how do they differ from other bearings?

Thrust cylindrical roller bearings are precision-engineered components designed to handle axial loads – forces applied parallel to the axis of rotation. They distinguish themselves from other bearing types through the use of cylindrical rollers arranged in a specific pattern. This design allows for efficient load distribution and precise control of axial movement, making them ideal for applications where accuracy is crucial.

2. In which European industries are thrust cylindrical roller bearings commonly used?

Thrust cylindrical roller bearings find widespread use in various European industries, including automotive, aerospace and defense, manufacturing and industrial machinery, and renewable energy. Their versatility and ability to handle axial loads make them a preferred choice in scenarios where precision, efficiency, and durability are priorities.

3. What advantages do thrust cylindrical roller bearings offer to European manufacturers?

The advantages of thrust cylindrical roller bearings for European manufacturers are numerous. These bearings enhance productivity by minimizing downtime, reduce maintenance costs, and contribute to sustainable manufacturing practices. Their precision engineering ensures accurate operation, making them suitable for applications where precision is paramount.

4. Are there any limitations to using thrust cylindrical roller bearings?

While thrust cylindrical roller bearings excel in handling axial loads, they may not be the optimal choice in scenarios where radial loads are predominant. In such cases, other bearing types, such as radial ball bearings or spherical roller bearings, may be more suitable. Additionally, space constraints or specific environmental conditions may influence the choice of bearings.

5. How can European industries benefit from adopting thrust cylindrical roller bearings?

European industries can benefit significantly from the adoption of thrust cylindrical roller bearings. These benefits include improved efficiency, reduced maintenance costs, and sustainability. By embracing the advantages of these bearings, European manufacturers can maintain their competitive edge and contribute to the region’s industrial growth and innovation.

In summary, thrust cylindrical roller bearings are critical components that play a pivotal role in enhancing the performance and reliability of machinery in European industries. By understanding their unique features and advantages, manufacturers can make informed decisions that lead to improved productivity, cost savings, and sustainable manufacturing practices.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8