Marine Shaft Grounding Brushes: Essential Devices for Preventing Corrosion and Bearing Failure

Marine vessels rely on intricate mechanical systems to function efficiently, and among these, the propulsion shaft stands as a critical component. However, the performance and longevity of this essential part can be severely compromised by electrical issues such as stray current corrosion and bearing damage. This is where marine shaft grounding brushes come into play. These specialized devices are pivotal in safeguarding shipboard machinery, ensuring a longer operational life, and minimizing costly maintenance. In this article, we will explore the crucial role of shaft grounding brushes in marine applications, how they work, and why they are indispensable for maintaining the reliability of modern vessels in demanding maritime environments.

Types of Marine Shaft Grounding Brushes

Overview of Different Shaft Grounding Devices

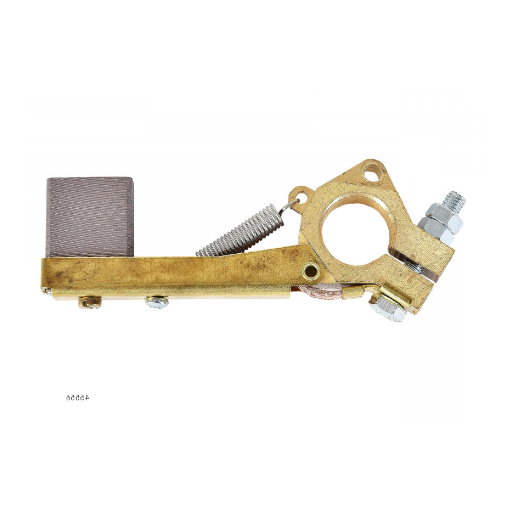

Marine shaft grounding devices are crucial components designed to deter electrical discharges from jeopardizing the ship’s bearing systems. The shaft grounding devices protect against bearing damage from electrical currents generated by the rotating shafts of marine propulsion systems. Several different types of shaft grounding brushes exist that can be used based on operational requirements and the type of vessel.

- Carbon-Based Brushes: Carbon grounding brushes are probably the most common in marine applications, mainly because carbon is a good conductor and is very durable. In general, these brushes are applied directly to the shaft; they pick up stray electrical charges and divert them safely to the ship’s hull. The carbon’s low resistance helps to protect the grounding brush itself as well as the shaft by allowing an efficient discharge.

- Metal Fiber Brushes: Metal fiber brushes are generally made of highly conductive alloys and use another common shaft grounding system. These brushes perform better in high-load situations and are, in that regard, more suited to heavy-load carrying vessels such as cargo and tanker ships. The sturdy construction ensures that the brushes remain operative even in the harsh conditions, continuously experienced by propulsion systems.

- Hybrid Grounding Devices: Hybrid designs integrate elements of both carbon and metal brushes to give the best performance in a range of operations. These systems are designed with a compromise on conductivity, durability, and maintenance for those vessels that require a flexible and highly efficient grounding solution. They have particular value in high-tech propulsion systems such as those used in modern hybrid or electrically-powered vessels, where control over electrical discharge is extremely important.

Each type of shaft grounding brush plays a pivotal role in minimizing the electrical pitting and wear of important components of the ship, assuring the reliability of the vessel, and providing economical operation in these challenging maritime environments.

Specific Applications of Each Type

The type of shaft grounding brush employed depends upon characteristics of the ship, operational requirements, and propulsion technology. For example, carbon-based grounding brushes are commonly used in traditional vessels with diesel power. These brushes make the electrical discharge build-up more manageable in simpler systems, thus safeguarding bearings from damage and prolonging their operational time.

Silver-graphite shaft grounding brushes, however, are mainly in use in the modern hybrid or electric-type propulsion systems. They have been designed to meet high conductivity requirements with the best electrical grounding. Because they do not wear out easily and therein lies the high efficiency, these brushes are suitable for systems that require precision, such as those used in passenger ferries or naval vessels.

Special shaft grounding systems, such as metallic fiber brushes, are indispensably engineered for higher-performance vessels running under extreme operating conditions. These are suitable for ships having variable-speed propulsion systems, such as research vessels or offshore-support vessels. These provide efficient, adaptable grounding and enhance reliability in a difficult environment with less maintenance. The very particular servicing of these types serves to highlight how critical grounding brush types are to different maritime activities.

Comparison of Materials Used in Shaft Grounding Brushes

These brushes for shaft grounding are generally manufactured from graphite, copper, and silver, each material having its own peculiar electrical and mechanical properties. Graphite is popularly used because it offers great conductivity and heat resistance. It can wear out at very high speeds, which is an advantage because its fine wear allows the brushes to adjust better against the shaft surface. Such self-lubrication reduces friction and wear on both the brush and the mating surface, making it a very efficient medium for long-term use in a number of working conditions.

Copper brushes, therefore, excel in situations where it’s desired to have a very high level of conductivity. They offer much less resistance to electric current than graphite ones do, so copper-based brushes are best for a situation wherein you have to be concerned about having a voltage drop inconsequential in any respect. Still, copper is not as resistant to wear as graphite—the operating life would therefore ordinarily be shorter, and this means that there would be many replacements. Hence, the usage of copper brushes is more in those environments which allow for operational efficiency versus the call for durability.”

The silver grounding brush is the finest among the three, providing the maximum conductivity and the lowest contact resistance. Hence, they suit applications for high-performance requirements in specialized industries wherein precise grounding is of paramount significance. Although highly efficient, the cost of silver restricts its usage to those few systems that truly qualify for that performance level, such as advanced maritime technologies and precision electronic instrumentation. The choice of material ultimately balances cost, durability, and performance, tailored to the unique demands of the application.

Benefits of Marine Shaft Grounding Brushes

Enhancing Safety on Vessels

The marine shaft grounding brushes act as one of the essential safety elements for vessels to minimize any dangerous electrical imbalance that otherwise could have arisen to compromise their working. For obvious reasons, these brushes are designed to mitigate the stray currents caused by the electromechanical interface created between the rotating shaft and electrical systems applied, along with seawater conductivity. Unrestrained stray currents can painfully destroy by pitting corrosion and overheating of propulsion equipment, thus giving rise to catastrophic mechanical failures.

Modern grounding systems are not just designed to redirect these stray currents but also provide a consistency in the resistance readings even after prolonged exposure to all the confrontational maritime conditions. Research reveals that the application of advanced grounding systems coupled with regular monitoring cuts down the odds of an electrical discharge event by over 85%. Furthermore, the reduced risk is directly proportional to longer equipment life and greater reliability of backbone shipboard systems.

The implementation of such precision grounding solutions, therefore, helps vessels to meet increasingly stringent safety standards put forward by international maritime regulatory agencies, including the International Maritime Organization (IMO). These safety protocols, once aligned, thereby assure operational integrity and compliance towards safer seas and less downtime occasioned by preventable equipment malfunctions.

Reducing Wear and Tear on Bearings

The bearing life cycle remains highly influential over a vessel’s machinery’s efficiency and reliability. Wear and tear may come from misalignment, improper lubrication, vibration, or an aggressive operating environment. Bearings suffer mostly when thermal expansion, great loads, or high speeds push the working boundaries of the component. Neglecting maintenance and anti-wear engineering solutions will exacerbate these mechanisms.

Proper lubrication forms the most prominent feature in limiting bearing wear. Automatic lubrication systems, coupled with real-time monitoring, allow for bearing lubrication delivery in minute quantities with precision to reduce friction and temperatures during operation. That technique stabilizes the lubricating film under great load conditions, preventing the surfaces from contacting directly. The introduction of synthetic lubricants with enhanced anti-wear properties positively augmented such bearings’ resistance to hostile marine environments. These synthetic oils and greases had to be out under more considerable temperature and load variations and thereby became instrumental in severe operating conditions.

Further, vibration analysis and thermal imaging are used more and more as predictive tools for minimizing wear and tear on bearings. Such technologies help engineers detect early incidences of misalignment, imbalance, or poor lubrication before anything major occurs. Vibration analysis can, for example, pick out irregularities within rotating equipment by measuring their vibration spectrum, whilst thermal imaging detects abnormal heat distributions that may reveal excessive friction or wear. By utilizing these diagnostic means in condition monitoring systems, the operators can optimize the bearing resources for maximum bearing performance and extended service life at a lesser risk of unforeseen failures that hurt the operations of the vessels.

Improving Operational Efficiency

Operational efficiency is a very important factor in the sustainability and profitability of any maritime industry operation. One of the ways in which this can be achieved is by installing a sophisticated predictive maintenance system with condition monitoring features that detect problems early. Based on data from sensor arrays and various analyses performed in real-time, these systems apply machine learning algorithms that help operators foresee equipment failure with great accuracy. For example, vibration monitoring would alert the operators to imbalances or misalignments that might still be small in magnitude, affecting the engines, whereas oil analysis might indicate contamination and warn of possible lubrication breakdown. These insights help minimize unplanned downtime and provide room for better asset management.

Unsurprisingly, the deployment of connected IoT devices further contributes to operational transparency. These interconnected devices gather vital performance data from all systems, including propulsion, navigation, and auxiliary systems, while this data is channeled into central dashboards for holistic analyses that guide operators in fuel optimization, maintenance planning, and waste reduction. This real-time analysis of operational metrics also supports vessels in environmental reporting, improving emission monitoring, and compliance with regulations, all of which steer the industry towards greener and more efficient operations.

Lastly, integrating automation with AI-driven analytics lays the groundwork for overall process optimization. Having analyzed historical data, these platforms can give prescriptive recommendations that assist in the optimization of operations on strategic and tactical levels. As an example, route optimization algorithms can ingest weather data, fuel load, and traffic conditions to resolve the most fuel-efficient and shortest routes for the vessels. The consolidation of these advancements leads to a more efficient operational framework and thus, confers on top operators a certain competitive advantage in an increasingly demanding global marketplace. With their continued refinement, these processes promise long-term gains in cost-cutting, enhanced reliability, and longer operational life for equipment.

Installation and Maintenance Best Practices

Steps for Proper Installation of Shaft Grounding Devices

- Conduct Preliminary Systems Evaluation: Before installation, carry out a detailed assessment of the configuration and working environment of the system. Analyze the shaft size, rotational speed, and electrical characteristics of the equipment. Incompatibility of the grounding device with machinery requirements will lead to unsatisfactory performance.

- Prepare the Installation Surface: Clean the surface of the shaft properly to make sure that all contaminants, such as dirt and powder, may be removed. This would ensure bulk electrical conductivity and avoid any insulation problem from being created by foreign particles. Consider applying a solvent and ensure the material is solvent-compatible so as not to damage the surface during cleaning.

- Mount the Grounding Device Securely: Install the shaft grounding device, making sure that it is well-aligned with the axis of rotation of the shaft. Mount the device using the proper clamps or mounts for the device, as recommended by the manufacturer. Follow the recommended torque values in the directions; over-tightening or leaving connections loose must be avoided at all times.

- Establish Proper Electrical Connections: Connect the shaft grounding device with electrical conductors rated for grounding, resistant to corrosive agents, and safely worked. The connection must follow the electrical code standards of the system to ensure that the device will indeed operate at its best possible performance and will be protected from electrical faults.

- Test the Installation: A complete testing procedure will prove that the device can work to eliminate stray currents. Voltage levels and resistance will be monitored rigorously with the use of a multimeter to check that the system conforms to pre-established parameters. Keep records of all test results for referencing during later maintenance.

- Perform Routine Maintenance: Initially, schedule periodic inspections to assess the status and conditions of the grounding device. Then, look for early signs of wear, corrosion, or poor alignment. Next, carry out the replacement of worn components or recalibration to keep the device in its best working condition throughout the project life.

Once applied, the above steps would ensure that shaft grounding devices are installed and maintained for maximum efficiency and equipment protection.

Routine Maintenance to Ensure Long-lasting Performance

Good maintenance practices are required to maintain the functionality and efficiency of shaft grounding machines over time. Periodic cleaning of the device makes sure that dust particles, grease, and dirt do not hinder electric conductivity and add wear. Use gentle cleaners and soft materials to prevent damage to sensitive components.

Check to ensure that the brushes are contacting the shaft properly, and if uneven wear is present, it can adversely affect the grounding. Replace the brushes when they are close to their wear limits. This should be done according to the specified replacement interval set forth by the manufacturer. Also, ensure that the mounting hardware, in all respects, is held securely and protected against corrosion so that operational stability is maintained.

Periodic monitoring of electrical resistance is required to gauge a possible decline in performance. Use a high-precision multimeter or equivalent diagnostic tool to take resistance measurements and contrast these against the acceptable range defined in the technical specifications of the device. Any significant deviation might point to recalibration or even component replacement being required.

By merging these routine checks with advanced sensor technology and predictive maintenance analytics, organizations can better optimize the maintenance schedule. For instance, real-time monitoring tools are available today to provide granular insights that could anticipate a failure. Being among the early adopters of such a technology can drastically reduce downtime while promoting the enhanced reliability and lifespan of equipment.

Common Mistakes to Avoid During Installation

- Skipping Pre-Installation Site Assessments: One of the most common mistakes is failing to perform a thorough site assessment before installation. A proper assessment ensures that the environment is suitable, including sufficient space, a safe foundation, and environmental conditions such as temperature and humidity to allow optimal functioning of the equipment. Skipping such an assessment could lead to non-functionality or premature aging.

- Incorrect Alignment and Leveling: One critical misstep during installation is misalignment, causing induced stresses upon the mechanical components, which accelerate degradation or become inefficient in operation. The use of precision instruments like laser alignment systems should be adopted to ensure proper leveling and alignment.

- Non-Compliance with Manufacturer Instructions: Many problems stem from the blatant disregard or inadequate comprehension of the manufacturer’s instructions for installation. These instructions often contain important details on how to fasten connections, configure control systems, and verify tolerance levels. If the equipment is installed contrary to the manufacturer’s instructions, warranties may be invalidated, and equipment safety jeopardized.

- Underestimating Electrical Requirements: Neglecting to verify the equipment-specific power and grounding requirements is a recipe for inefficiency and a safety hazard. It is essential to have a licensed electrician verify voltage compatibility and confirm compliance with local codes before installation.

- Not Testing and Validating after Installation: Yet another costly mistake is to neglect the required methodical testing and validation of the system after installation. The initial run should be thorough and include diagnostic tests for all critical components to ensure that any potential problems are identified at an early stage and that the system is functioning as it was supposed to.

By avoiding these common pitfalls, installations can be accomplished without friction and, in turn, improve the equipment’s long-term reliability.

Technological Advancements in Shaft Grounding

Innovative Materials Enhancing Durability

I am of the strong opinion that the use of advanced materials brought some sort of revolution in shaft grounding performance and lifespan. The breakthrough has been the utilization of composite materials and high-performance alloys that offer better wear and corrosion resistance than their so-called traditional counterparts. The materials generally retain their structural integrity even in adverse environments, maximizing their grounding function through prolonged operational periods of time.

Also, great strides in coating technologies have contributed significantly to ensuring durability. New-age coatings such as nanostructured ceramics and plasma-sprayed thermoplastics resist mechanical abrasion as well as chemical attacks. This, therefore, reduces the chance of premature failure, especially when in-service machinery is subjected to heavy stress or a corrosive environment.

The use of conductive polymers and carbon-based composites has brought an efficiency angle to shaft grounding systems hitherto unheard of. These materials provide good electrical conductivity together with heat resistance, which is very important in resisting wear effects due to heat buildup. I further believe that this improvement will keep going as material science continues in the research mode, and therefore will establish newer standards for industrial applications.

New Designs for Improved Effectiveness

The domain of shaft grounding has moved significantly in terms of evolved structural designs to achieve better performance. The recent design trends for these layers emphasize the use of composite materials that offer both mechanical strength and good conductivity. Nanostructured layers have been included to provide the best electron mobility, lowest resistance, and highest efficiency in stray current discharge. Such configurations minimize the concentration of heat and thereby eliminate the possibility of failure through localized thermal stresses, this being most important in applications of high-speed motors or generators.

Also, the advent of advanced manufacturing techniques, such as the ones encompassing precise laser machining and additive manufacturing, has altogether revolutionized the production possibilities in this regard. Laser machining allows achieving micron tolerances to improve alignment and surface contact in the grounding brush or ring to increase operational reliability. Additive manufacturing, on the other hand, allows the production of complex geometry components that were hitherto impossible to fabricate by traditional means. These methods, integrated with online diagnostics of the system, permit the institution of predictive maintenance measures to minimize downtimes and thus maximize the life duration of the critical grounding equipment.

Lastly, continuous monitoring and feedback concepts are fast becoming embedded in design philosophies. Further data concerning occurrences such as voltage spikes, thermal gradients, or current discharge levels can be made available through sensors embedded within the grounding system. The data are then employed with an overarching industrial Internet of Things (IIoT) platform to identify patterns and foresee failures, thus encouraging a maintenance culture founded on data. With such integration, operational risks are minimized alongside adherence to current safety and efficiency standards. These advances essentially give a leap to the conceptualization and implementation of shaft grounding systems for the next industrial era in present-day performance and sustainability topics.

The Role of Marine Shaft Grounding in Sustainable Operations

Contributions to Marine Engineering

Marine shaft grounding systems ensure the uninterrupted operation of modern vessels and, hence, their safety. When these accidental electrical shocks between the shaft and the surrounding structure develop, they quickly lead to galvanic corrosion, threatening the life and integrity of marine components. This must be prevented to prevent auxiliary machinery from suffering damage due to electrical discharge and mechanical wear.

In terms of engineering, this advancement in shaft grounding technology has replaced traditional materials with silver-graphite brushes, a value addition in terms of superior conduction of electricity through current. Another step is the introduction of continuous monitoring systems, which utilize real-time data acquisition to alert engineers to abnormalities in the electrical grounding, so can then carry out preemptive maintenance. All these development trends suggest shaft grounding technologies under condition-based maintenance (CBM) and predictive analytics.

In a way, the use of these systems falls into the category of more stringent regulations that govern emission reduction and energy efficiency in marine operations. With proper grounding, such operations are not fraught with interruptions caused by electrical damage. By comparison, such interruptions disrupt smooth mechanical operations and cut down on fuel efficiency, down the line increasing greenhouse gas emissions. In harmony with such international codes as IMO’s EEDI, shaft grounding systems stand to promote both sustainability and engineering excellence in the marine sector.

Impact on Vessel Sustainability

When shaft grounding systems are implemented on a vessel, it greatly helps to increase its sustainability while protecting the environment and following the existing global standards. In the pursuit of five examples, the following considerations delineate the tangible influences such systems bring about on the environment and conservation:

- Reduction in Fuel Consumption: Electrical interference is kept to a minimum, and mechanical operations are optimized; thus, shaft grounding systems assist in reducing fuel consumption by 2-5%. This fuel conservation results in savings in operational costs and also reduces reliance on fossil fuels.

- Reduction in greenhouse Gas (GHG) Emissions: Lower fuel consumption means fewer GHG emissions, including carbon dioxide (CO2) and nitrogen oxides (NOx). For example, a medium-sized cargo vessel can lessen its emissions of CO2 by 500-1,000 metric tons on average every year.

- Adherence to Regulations: Such systems ensure that vessels comply with emission and energy efficiency standards across the world, such as IMO MARPOL Annex VI and Energy Efficiency Existing Ship Index (EEXI). Compliance ensures the ability of vessels to continue operating within important global markets.

- Increased Life of Equipment: By lessening electrical damage and pitting corrosion on propeller shafts, these grounding systems extend the life of mechanical components, in turn reducing the replacement of parts and therefore also reducing manufacturing emissions and material wastage.

- Better Electrical System Efficiency: Proper grounding of an electrical system will reduce energy loss, making sure power distribution on the vessel is operating at peak efficiency. This results in a sustainable use of onboard resources and power.

How these issues are confronted sets the very basis on which grounding systems demonstrate their importance in the chain, promoting sustainability while allowing marine operations to be balanced on operational and economic efficiency.

Long-term Benefits for the Marine Industry

The implementation of advanced shaft grounding systems has substantial long-term benefits for marine industries in terms of sustainability and operational improvements. One vital advantage derived from the system is its ability to reduce premature wear in the propulsion systems because it prevents electrical discharge damage that would affect vital components such as the bearings. This then adequately extends the lifespan and operation of systems, resulting in decreased maintenance and costs.

Increased efficiency with less energy loss means less fuel consumption and the resulting output of emissions, which further adheres to universal initiatives like the IMO’s carbon intensity reduction measures. Thus, efficiency gains over the operational life of a vessel translate into heavy savings and a marked reduction in environmental burden.

Very recently, these technologies have found use in environmental compliance; thereby increasing the support of industries that require sustainable development and promoting the early adopters as an exemplars in environmental responsibility. This technology, therefore, promotes the path of greener maritime by supporting the rise of the ever-growing trend of hybrid and electrification propulsion.

Frequently Asked Questions (FAQ)

Q: What are marine shaft grounding brushes?

A: Marine shaft grounding brushes are devices used in marine applications to prevent the buildup of static electricity and to protect against galvanic corrosion. They are installed on the shaft of a marine vessel and provide a continuous electrical connection to the water, ensuring that any stray currents are safely dissipated.

Q: How do marine shaft grounding brushes work?

A: Marine shaft grounding brushes work by creating a conductive path between the metal components of the vessel and the surrounding water. This allows any induced electrical currents to flow harmlessly into the water, reducing the risk of corrosion on the shaft and other metal parts of the vessel.

Q: Why are marine shaft grounding brushes important?

A: Marine shaft grounding brushes are important because they help protect the metal components of a vessel from corrosion caused by stray currents. Without proper grounding, these currents can lead to significant damage, affecting the longevity and safety of the marine vessel.

Q: Where are marine shaft grounding brushes typically installed?

A: Marine shaft grounding brushes are typically installed on the propeller shafts of marine vessels. They are strategically placed to ensure optimal contact with the shaft and are usually mounted on the hull or directly on the shaft itself.

Q: How often should marine shaft grounding brushes be inspected?

A: Marine shaft grounding brushes should be inspected regularly, ideally during routine maintenance checks. Frequent inspections help ensure that the brushes are in good condition, properly aligned, and functioning effectively to prevent corrosion.

Q: Can marine shaft grounding brushes be replaced?

A: Yes, marine shaft grounding brushes can be replaced when they become worn or damaged. It is important to use high-quality replacement brushes to maintain effective grounding and protect against electrical corrosion.

Q: What materials are marine shaft grounding brushes made from?

A: Marine shaft grounding brushes are typically made from conductive materials such as copper or graphite. These materials are chosen for their excellent electrical conductivity and resistance to corrosion in marine environments.

Q: Are marine shaft grounding brushes required by regulations?

A: While not always mandated by regulations, marine shaft grounding brushes are highly recommended by marine industry standards and best practices. Many classifications and safety organizations advocate their use to enhance vessel safety and longevity.

Q: How do I choose the right marine shaft grounding brushes for my vessel?

A: Choosing the right marine shaft grounding brushes involves considering factors such as the size of the shaft, the type of vessel, and the specific marine environment. Consulting with marine electrical experts can provide guidance on selecting the most suitable brushes for your needs.

Q: Can marine shaft grounding brushes help reduce maintenance costs?

A: Yes, by preventing corrosion and reducing the risk of electrical damage, marine shaft grounding brushes can ultimately lower maintenance costs. Regular use and proper installation of these brushes contribute to the overall health and performance of the vessel, leading to fewer repairs and longer service life.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8