How to Choose the Right Bearing for Your Application: A Comprehensive Guide

Selecting the appropriate bearing is a critical decision that can significantly impact the performance, efficiency, and longevity of your application. Whether you’re designing industrial machinery, automotive systems, or precision equipment, bearings play a fundamental role in minimizing friction, supporting loads, and facilitating smooth motion. However, with numerous types, materials, and specifications available, choosing the right bearing can be a daunting task. This guide is designed to provide you with a clear, in-depth understanding of the factors to consider and the steps to take when making this decision. From analyzing operating conditions to evaluating load requirements, we will explore key elements that ensure your selected bearing meets the exact demands of your application.

What are the Different Bearing Types Available?

Understanding Ball Bearings and Their Uses

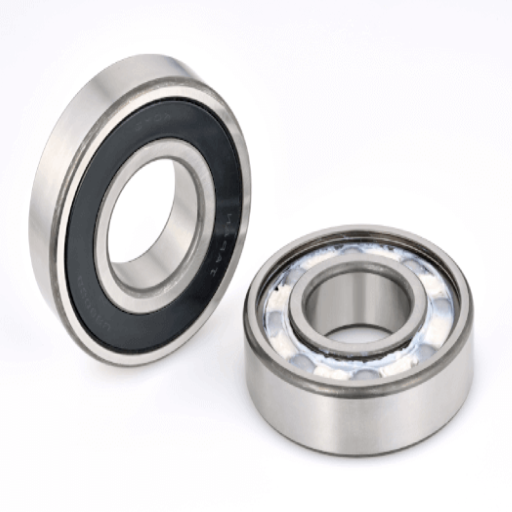

Due to their applicability and reliability ball bearings tend to be one of the most commonly used types of bearings. Each bearing consists of spherical balls positioned in the middle of two concentric metal rings or races, which facilitates smooth rotation while minimizing friction. Ball bearings are best suited for applications that require low rotational resistance along with minimal axial or radial load support.

Ball bearings are found in electrical motors, components of automobiles, household appliances, as well as precision instruments. This is due to low to mid-level load conditions unmatched with high speed requirements. Their design ensures optimal performance in an array of different segments, industries where efficiency alongside precision are critical. One of their most impressive benefits is the ability to provide remarkable results without sufficient lubrication, which in turn makes maintenance straightforward and cost-effective.

Due to the application of these ball bearings being highly versatile, meticulous factors such as load requirements, tolerance to misalignment, and operating speeds tend to be critical. Heavy loads with angled disparity misalignments tend to need solutions unlike roller or spherical bearings. Despite that, these are ideal for most consumers and standard industrials due to dependability.

Exploring the Benefits of Roller Bearings

Bearings tend to perform better with heavier workload shock due to their roller-type construction when compared to ball bearings. The roller’s advantages perform well in industrial bearings like construction, automotive, and manufacturing since it efficiently distributes workloads owing to its bigger surface area when in contact with raceways and rolling parts.

Roller bearings can also manage radial and axial loads at different levels by controlling their design. For example, thrust and radial loads are evenly distributed in tapered roller bearings unlike in cylindrical roller bearings made specifically for radial loads. With these modifications roller bearings can achieve specific target requirements while maintaining superb reliability across different conditions.

Sustained performance under severe vibration, heavy impacts with debris makes spherical roller bearings perfect example for extreme accuracy and sturdy operational environments. Bearings function properly even during severe vertical and true misalignments. These attributes combined displays the extent roller bearings provide in areas require the utmost to improve productivity while reducing the chances of operational halts.

How Do Tapered Roller Bearings Work?

Tapered roller bearings are particularly adept at coping with combined (radial and axial) loads due to their specific design. It includes an inner ring or the cone, an outer ring referred to as the cup, and a set of rollers with a trapezoidal sectional shape in between. This construction permits the taper to sustain forces in both axial and radial directions along the rollers and raceways, which diminishes the stress on the bearing, increasing its longevity. As a result of the design, tapered roller bearings perform best in situations where there is high stress and precision control under careful management is required.

The working principle of tapered roller bearings is that the components are aligned in such a way that there is contact between the rolling elements and the raceways of the bearing. Application of load will lead the bearing to convert forces into motion, aiding free rolling of the part, which further minimizes friction and wear. To enhance clearances between rolling elements and the contact surfaces, bearings are preloaded during installation, which guarantees proper functioning even when subjected to dynamic changes of speed and load.

Applications like automotive wheel hubs, industrial machinery, and gearboxes frequently employ tapered roller bearings. These bearings can withstand significant amounts of torque while staying perfectly aligned, which makes them ideal in situations where durability and performance are both critical. Furthermore, these bearings come in different configurations such as single-row, double-row, and four-row designs, which help meet specific operational needs and improve mechanical efficiency in various systems.

How to Choose the Best Bearing for Your Needs?

Factors to Consider in Bearing Selection

Analyzing a few crucial factors is important while choosing bearings for a specific application to make sure that their performance, reliability, and life span are optimal. These factors are dependent on operational needs, loading conditions, external conditions, and many more. Given below are some of the main factors to consider while selecting bearings for an application:

- Load Capacity: Consider the type and magnitude of the bearing’s load, including radial, axial, or combined. Load bearings are highly heterogeneous in accommodating to these forces; for example, spherical roller bearings can accommodate radial loads while the upper halves of angular contact ball bearings excells at axial loads.

- Speed Ratings: As a rule, every bearing has upper bounds to its operational speed that is set by the shape of the bearing and its lubrication system. Higher speeds add more requirements to the type of the heat shield bearings used like precision or ceramic ones, which merit temperature management features.

- Material Composition: The composition of the bearing determines its strength along with protection from erosion, wear and tear, or spikes in temperature. For low-profile applications, the preferred material would be stainless steel. In contrast, hybrid ceramic serves well for high speed, corrosive applications.

- Environmental Conditions: Evaluate ranges of temperatures, contamination exposure, vibrations, and moisture levels. If the environment has dust, water, or chemical agents, then a sealed or shielded bearing is necessary.

- Lubrication Requirements: Proper lubrication ensures the smoothest operation by reducing friction, heat, and wear. For oil or grease lubrication, the level of maintenance, speed, and load of the application dictates the choice. For low maintenance, long lasting applications, advanced solid lubricant systems may be suitable.

- Mounting and Alignment: Misalignment or improper mounting can have a detrimental effect on the bearing’s life and performance. These risks may be countered with self-aligning bearing types or systems designed for ease of installation.

- Size and Space Constraints: Ensure the specified bearing falls within the designed space and fit limitations. In applications where space is restricted, thin-section bearings are preferred.

Considering all of these factors and design standards like ISO 281 or ABMA’s recommendations enables engineers to enhance system efficiency while reducing the chances of failure.

Evaluating Bearing Performance for High-Speed Applications

In high-speed applications, I first inspect bearing performance against specific criteria to ensure its dependability and proficiency in meeting intended outcomes. The first criterion I analyze is the speed range of operation of the bearing, commonly expressed as the product of the speed and the bore’s diameter. Bearings that operate at high speeds must have ancillaries such as heightened lubrication systems, lower internal friction, and less mechanical resistance from materials shifting at high speeds. For this reason, I look at whether the bearing’s design features adequate lubrication mechanisms like low viscosity grease or oil-air lube systems that restrict wear and tear and overheating.

I combine other equally imperative criteria, among them, the topmost being the bearing’s precision level, as it is another one of the bearing’s attributes where sustaining accuracy of operation at high speeds requires tight tolerance bands. Manufacturing grade bearings, like ABEC-7 and upward in class under ANSI, are generally considered to provide the requisite accuracy, precision, and non-vibrational functionality. In addition, I consider the limit of dynamic load and the limit of sustained damage to bearing components in the course of cyclic forces rotating at high speeds, as tested to check if they do unendurable damage, that is, reduced durability.

Lastly, I analyze the materials and structure of the bearing. Due to the above having less weight, loss of heat and energy, and better thermal stability, advanced materials like ceramics, or hybrids with steel raceways and ceramic rolling elements, are likely to be more useful. Considering these factors, along with exhaustive performance evaluations with simulated operational testing, allows me to ascertain whether the bearing can sustain the demanding criteria for high-speed utilization.

Why is Lubrication Crucial for Bearing Performance?

Types of Lubrication for Optimal Bearing Functionality

Choosing the right lubricant type is important for bearing functioning and lifetime under different operational conditions. A lubricant makes the motion easier by decreasing friction, reducing wear, and dissipating heat, while also defending from corrosion and contamination. Lubricating bearings can usually be divided into two primary categories: grease and oil. Each of these types has its own characteristics that makes it suitable for particular use cases.

- Grease Lubrication: The semi-solid form of grease has a wide range of applications for low-speed and load range, as well as for low-maintenance tasks. Moisture and dirt can be kept away because it contains a thickener, an additive, and a base oil. Even when mounted vertically, the grease’s semi-solid nature makes certain parts stay in place. Furthermore, grease gets displaced more easily than oil, but it also has some disadvantages. Its nature means it has low heat dissipation, and a higher viscosity index makes it indispensable when paired with a certain temperature range and dropping point.

- Oil Lubrication: For applications with intense speeds, new oil applications sweeping the engineering field pose a competent means of heat removal. There are a few methods of lubrication: circulation, splash, or oil mist lubrication– all of which ensure the lubricant reaches the bearing surfaces. Furthermore, oils are categorized based on their viscosity grades; however, certain oils can undergo additional processing to improve resistance against oxidation, extreme pressure, and even wear. One of the key advantages of oil lubrication systems is that they are absolute in high stress areas; although they do require additional components like pumps, establishes, and filters.

- Solid Lubrication: In the case of a vacuum setting, or some of the most extreme temperatures, solid lubricants tend to outperform conventional lubricants. Molybdenum disulfide, or graphite, are a few examples of such solid lubricants.

In choosing the proper lubrication technique, paying close attention to the speed, temperature, and load of the application is indispensable. The requirements of mechanical systems that are more advanced than before is being met with modern advances in lubricant chemistry.

How Lubrication Affects Bearing Service Life

Proper lubrication plays an important role in the functioning lifespan of a bearing because it helps reduce the friction and wear of the bearing, controls the level of heat created, prevents contamination, and helps maintain cleanliness. Studies suggest that nearly 80% of bearings that have a reduced operational life are due to lubrication problems which makes lubrication a major concern for operational reliability.

- Reduction of Friction: Bearing lubrication improves the sliding and rolling motions of rotating components by creating a thin film between them, thus reducing the level of friction. By removing metal-to-metal contact completely, bearing lubrication improves the surface damage and energy usage.

- Prevention of Wear: A lack of lubrication increases abrasiveness such as scuffing, pitting, and scratching which can form into a layer that protects the surface. With proper bearing lubrication, smooth operations under severe shocks and huge loads become easier.

- Dissipation of Heat: Bearing rotation under high loads and extreme speeds can cause a large amount of heat to be generated. Because of lubricants, it is easier to maintain a nomal range of temperature while providing the movement.

- Protection against Corrosion: Sustaining the life of an oil is done by using greases or oils mixed with anti-corrosive additives that help in further degrading the chemicals that corrode the underlying surface. These oils and greases protect bearing metals from being corroded; protecting them from moisture and various contaminants that corrode the surface is extremely important throughout the process.

- Reduction of Contamination: Well-prepared lubricants reduce the chances of debris and dirt getting into the surfaces of the bearing part, removing the risk of these particles diminishing the bearing life.

These effects can be fully achieved by paying attention to the type of lubrication used, the amount, and the service intervals. Precision synthetic or special lubricants customized to the application are the best choice and maximize bearing performance while increasing the lifespan.

What is the Importance of Rigidity in Bearing Selection?

How Elastic Deformation Impacts Bearing Choices

Regardless of the complexity or type of application, an elastic deformation of a bearing will always determine whether or not the bearing can be used in a specific application. All materials have a specific elasticity, which determines how much deformational deflection will occur when a load is applied to a bearing. This assumes an automatic alteration of a contact surfacethe , surface of the bearing, which mandates the load distribution, which will influence, to an extent, the wear and tear as well as the thermal activity. Deranged deformity can unusually occur and lead to faulty distribution of stress, which can, and more often than not will, cause fatigue and failure.

Most applications of a bearing require low elastic deformation. For example, ceramics and hardened steel tend to deform the least when used with axial and radial loads, serving in angular contact ball bearings. Also, many of the modern designs use polymers, which also add and serve in low elastic casings. Other factors such as operating speed, possibility of exposure to temperature changes, rate of screw rotation can impact the deformation.

Because of advances in computer modelling, like finite element analysis (FEA), engineers are now able to better ‘predict’ bearing designs using more precise deformation simulation. Inesch EST Industries such as aerospace and robotics, even smallest elastic deformation during design phase is fundamental for functioning system robustness and dependability.

The Role of Rigidity in High-Load Environments

Rigidity is critical for maintaining structural components and systems operational precisely within high-load contexts. Typically, systems with high reliability requirements operate metals, like titanium, and composites which have favorable stiffness-to-weight ratios marking them as high performing within these domains.

Optimizing rigidity along with quantification is done through engineering disciplines with the assistance of modern tools like finite element analysis (FEA) and computational mechanics. These two approaches facilitate the simulation of stress and deformation patterns for various load conditions to aid engineers in mitigating flexural weaknesses in their designs. Moreover, systems also benefit from risk mitigation from additional factors like pre-stressing configurations or spider-web-like lattice frameworks, as the risk of failure during peak operational loads is shifted due to better load distribution.

Grain boundary engineering, heat treatment, or even additive manufacturing greatly customize the mechanical properties of the materials to exact application operational needs. By integrating such reliable techniques, industries reliant on heavy-load performing systems receive improved efficiency, increased safety, and elevated longevity.

How Do You Conduct a Comparison of Bearing Types?

Analyzing Radial and Axial Loads in Different Bearings

Both radial and axial loads mark the principal forces that bearings were made to handle, and diagnosing them accurately is key when evaluating whether a specific bearing would be appropriate for a certain application. Radial loads are forces applied to the shaft that require the bearings to provide sufficient radial support. Deep groove ball and cylindrical roller bearings are among the most popular bearing types that sustain high radial loads due to their design, which allows even distribution of load and minimum rolling resistance.

In contrast, parallel forces are termed as axial or thrust loads which act along the shaft axis. To efficiently control axial forces, angular contact ball bearings and thrust bearings are designed with contact angles optimized to bear these kind of stresses. It is worth mentioning that angular contact types provide twin directional axial load capability when installed in matching pairs.

Taper roller bearings effectively solve cases where there are simultaneous radial and axial forces because their conical shape can accommodate combined loads. Alongside dynamic load rating calculations that a bearing undergoes, tolerances to misalignment and bearing rotation speed also impact the bearing’s class selection. Optimized data on bearing load distribution and sophisticated simulations guarantee maximum performance, reliability, and operational life of bearings in various industrial systems.

Understanding Misalignment and Its Effects on Bearing Performance

An incorrect alignment and load application on bearings takes place when the shaft and the housing axes do not align correctly with one another. This results in an incorrect load being applied to critical bearing parts. These could stem from faulty manipulations during the fitting of the equipment, changes in the shape of the structural components, or even the thermal widening of machine parts during their functioning period. Even insignificantly small misalignments cause disproportionately large internal mechanical stresses, which result in damage to the rolling elements, raceways, and seals. Thus, the operational capability of the bearing, the level of frictional heat, and its wear and tear all worsen, tremendously reducing its lifetime.

These effects are worsened in high-speed processes where precision in rotation is of the utmost importance. For example, in the case of angular misalignment, a member of the rolling elements, as well as the raceways, undergo enhanced localized contact stress, which might lead to surface fatigue or even micro-pitting. Further deterioration could lead to spalling or even cracks, thereby degrading the overall performance of the bearing. Moreover, excessive shock-induced vibrations tend to worsen the problem of misalignment. As a result, adjacent structural elements of the machinery would also be negatively impaired. In addition to increasing destructive noise levels, such vibrations can adversely affect not only the bearing but also other neighboring components that suffer from noise-sensitive uses, making robotics or even medical equipment less effective.

Contemporary engineering works address problems associated with misalignment through the implementation of self-aligning bearings or adjustable mechanisms. More sophisticated bearing configurations, for instance, spherical roller bearings and self-aligning ball bearings, adapt their internal structures to ensure balanced load distribution, effectively mitigating angular misalignment. In addition, condition monitoring systems enable real-time monitoring if combined with methods such as measuring vibration, temperature, and even the health of lubrication fluids to indicate misalignment. Analytics drawn from these predictive frameworks enable decision-making to adjust bearings before impending outages during operations.

Choosing Between Spherical Roller Bearings and Cylindrical Roller Bearings

Bearings differ based on the needs of the application, the operating conditions, and the constraints of mechanical design. Spherical roller bearings are unique because of their capacity to compensate for misalignment and accept both radial and axial loads. This multifunctional capability makes them particularly helpful in high-range workload functions, for example, in mining, pulp and paper, and renewable energy systems, where shaft deflection or housing misalignment is routine. They withstand extreme working conditions like high levels of vibration and significant weight, which increases their operational lifespan.

In contrast, cylindrical roller bearings are used chiefly to bear high radial loads and work very well at high speeds, which makes them suitable for more precise applications like electric motors, pumps, and gearboxes. Their design is meant to reduce friction and rotational forces, making it more stable, improving the efficiency of rotating equipment. Also, cylindrical roller bearings have an inner and outer ring, which makes them easier to install and maintain in cases where routine replacement or servicing is anticipated.

When selecting bearings, some crucial factors to consider are the load profile, alignment tolerance, speed, and environmental conditions like temperature or contamination. Performance devaluation can be achieved through the use of analytical tools and simulations, helping engineers optimize bearing selection to elevate performance and operational reliability.

Frequently Asked Questions (FAQ)

Q: What are the different types of bearings available for various applications?

A: There are several types of bearings to consider, including deep groove ball bearings, angular contact bearings, radial ball bearings, and hybrid bearings. Each type is suited for specific applications, depending on factors like load capacity and speed.

Q: How can I determine the right bearing for my application?

A: To choose the right bearing for your application, consider important factors such as load capacity, bearing size, bore diameter, and the type of load (radial or axial). A selection guide can help you choose based on these criteria.

Q: What role does load capacity play in selecting bearings?

A: Load capacity is crucial in selecting bearings as it defines the maximum load the bearing can support. Choose a bearing that can handle the anticipated loads in your application to avoid bearing failure.

Q: How does runout affect bearing performance?

A: Runout refers to the deviation of the bearing’s rotation from its intended path. Minimizing runout is essential for precision bearings, especially in machine tool applications, to ensure accuracy and reduce wear.

Q: Why is bearing rigidity important in machine tool applications?

A: Bearing rigidity is important because it affects the precision and stability of the spindle in machine tools. High-precision applications require bearings with high rigidity to maintain accuracy under load.

Q: What are the benefits of using ceramic balls in bearings?

A: Ceramic balls offer advantages such as low friction, high-speed capability, and resistance to wear and corrosion. They are often used in high-precision applications where these properties are beneficial.

Q: How do I choose between ball bearings and tapered roller bearings?

A: The choice depends on the application’s load requirements. Ball bearings are suitable for moderate axial loads and high speeds, while tapered roller bearings can handle higher axial and radial loads.

Q: Can selecting the wrong bearing size lead to bearing failure?

A: Yes, selecting the incorrect bearing size can lead to premature bearing failure due to inadequate load support or misalignment issues. It is important to match the bearing size with the application’s requirements.

Q: Are there specific bearings recommended for high-speed applications?

A: Yes, bearings like deep groove ball bearings and hybrid bearings are often recommended for high-speed applications due to their low friction and efficient performance.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8