Difference Between Grease and Oil: Understanding These Essential Lubricants

Lubricants play a critical role in ensuring the seamless operation of countless machines and systems, from industrial equipment to everyday vehicles. Two of the most commonly used lubricants are grease and oil, each with distinct properties, applications, and benefits. But what sets them apart, and how do you determine which one is right for a particular purpose? This article dives deep into the core differences between grease and oil, providing you with the insights needed to make informed decisions about lubrication solutions. Whether you’re a professional in the field or simply curious about the mechanics behind these essential substances, this guide will equip you with a thorough understanding of their unique characteristics and practical applications.

Composition and Characteristics

Chemical Composition of Grease

Grease is a semisolid lubricant that is formed in stages, starting with primary components like base oil, thickener, and performance additives. The base oil usually makes up the majority of any grease, giving it its basic lubricating properties. Since the viscosity of the oil and its type affect the operational performance of greases at a given temperature range or under certain mechanical stresses, they perform differently.

The thickener acts as a sponge that absorbs the base oil and thus helps with the consistency of grease. The common thickeners are lithium soaps, calcium soaps, aluminum complexes, and polyurea compounds, each adhering some particular properties to the grease. Lithium-based thickeners, for instance, are admired for their versatility and water resistance and hence are widely used in industrial and automotive grease.

Performance additives are selected with the intent of enhancing specific grease properties. They may add or enhance oxidation stability, provide excellent corrosion resistance, or act as extreme-pressure (EP) agents, depending on the need. An anti-wear additive will protect the metal surfaces from wear, especially under high-load conditions, whereas the rust inhibitor will prevent the components from rusting due to moisture. The right combination of these ingredients will tailor the grease to any highly specific service requirements and environmental conditions it is designed to be subjected to.

Chemical Composition of Oil

Oil has a chemical composition that is varied and greatly influenced by the type and source of the oil. For instance, crude oil mainly comprises hydrocarbons, which are alkanes, cycloalkanes, and aromatic hydrocarbons. These belong to the category of compounds that consist mostly of carbon and hydrogen atoms arranged either in chains or in rings, which then form the base structure of oil. Hydrocarbons generally constitute about 85-90% of the crude oil, making them the largest chemical group present.

Besides hydrocarbons, crude oil contains other organic compounds such as sulfur, oxygen, and nitrogen compounds, which are collectively classified as heteroatoms. Although considered minor relative to others—usually from 0.05 to 5% by weight—sulfur compounds are critical since these compounds could corrode refining equipment and pose an issue if they enter the environment as sulfur dioxide. In like manner, oxygen and nitrogen compounds are present only in trace amounts but often affect oil stability and other chemical properties in particular applications.

The other constituents in crude oil include trace metals, including vanadium, nickel, and iron. Even though the metals exist in much smaller concentrations, they can affect in one way or another the refining processes, the behavior of catalysts, or even the final quality of the petroleum products produced. The overall combination of chemical composition of the oil defines the behavior of the oil, its usability, and what would be required to process it for further use in energy and industries. Henceforth, a study of these chemical characteristics should render optimized methods for extraction, refining, and ultimately, utilization of the oil.

Difference in Consistency and Formulation

The consistency and formulation of crude oils differ remarkably based on their origin and chemical composition. As such, crude oils go from being light, almost fluid-like substances with low viscosities, to being heavy, tar-like substances. Massively because of the hydrocarbon chain differences- lighter oils have shorter hydrocarbon molecules, while the heavier oils have longer and more complicated molecular structures. Such differences affect transportation of crude oils, refining of crude oils, and eventually the use of refined petroleum products like gasoline, diesel, or lubricants.

Formulation differences, conversely, affect crude oil percentages of non-hydrocarbon compounds such as sulfur, nitrogen, and metals. Great-sulfur or “sour” crude necessitates desulfurization treatment in the crude oil refinery to fulfill the environmental standards, while the less-sulfur or “sweet” one normally has a much easier time being processed and hence preferred. Likewise, metals unsuspectedly occur in the crude and present refiners with problems, like vanadium or nickel actions that deactivate the catalysts or corrode equipment, compelling the refiners to use some precautions or treatment.

Addressing and taking into account these interceptions in consistency and formulation are very fundamental to the efficient carving and end-use application. Refineries are far better if they can customize their processes for specific crude grades and are bona fide in communicating with equipment as well as binding themselves by environmental legislation. Industry, when it properly analyzes and deals with the various properties of crude oils, can give value and a better place in the market for petroleum products.

Performance and Functionality

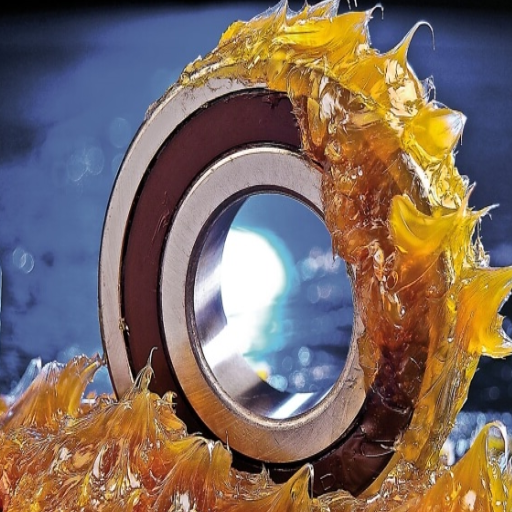

How Grease Works in Machinery

Grease is essential in machinery since it acts as a lubricant, reducing friction and wear between moving parts. Grease consists of base oil, thickeners, and additives that together give it the necessary performance specifications for a wide range of operating conditions. Unlike liquid lubricants, grease will stay in place for a long period; hence, grease applications include instances of infrequent or difficult relubrication. The grease used in mechanical operations is altered by its chemical constitution, operating environment, and method of application. Here are five detailed functions of grease and the associated benefits for machinery:

- Reduces Friction and Prevents Wear: Grease lubricates interface surfaces and thus reduces metal-to-metal contact, friction, and wear to a significant extent, thereby increasing the life of engine components and bearings.

- Sealant Property: Grease acts as a barrier to prevent contaminants such as dirt, dust, or water from entering the sensitive parts, and hence, this sealing action becomes very important in the industrial environment.

- Does Not Leak: Grease, unlike oil with a semi-liquid nature, prevents leakage from open or semi-closed systems during operation, offering the advantage of lubrication for a very long time.

- Temperature Stability: There are special greases that can withstand extreme temperatures with a wide-ranging variation-from below freezing to extreme heat. The temperature stability proves excellent lubrication, preventing failure under highly demanding conditions.

- Longer Maintenance Schedule: Because grease can stay in working points and maintain its integrity while under stress, a longer maintenance schedule is required, reducing downtime and servicing costs related to machines.

With these properties, grease categorizes the industrial, automotive, and aerospace sectors as indispensable lubricants, bringing about the best and utmost reliability of mechanical systems under various conditions.

How Oil Functions as a Lubricant

Primarily, oil is an all-purpose lubricant that carries some specific characteristics that help ensure the smooth operation and long life of any mechanical system. Being a liquid, oil efficiently flows between the moving parts, thereby building an oil film on the surfaces of the moving parts to prevent wear and reduce friction.

- Friction Reduction: Oil essentially creates a thin film between two metal surfaces, minimizing direct contact and, hence, friction. It acts against any loss in energy, increasing efficiency while heat is not allowed to be created. In some industrial situations, studies have proven that when the right kind of oil lubrication is applied, friction values can be decreased by almost 80%.

- Heat Dissipation: As a heat conductor, the oil takes heat from the contact surfaces and, through conduction, dissipates it to the environment, thereby preventing any possible overheating. This thermal management takes on an extra meaning in systems wherein the surface temperature can reach hundreds of degrees Fahrenheit, usually considered high-speed, high-load, and extreme situations. For example, automotive engine oils have to withstand up to 250°F (121°C).

- Contamination Removal: It will carry contaminants such as dirt, metal particles, and debris away from critical components. Usually, modern lubricant oils are combined with additives that suspend impurities to prevent sedimentation and ensure a clean internal environment. Furthermore, regular oil filtration systems can filter out particles as small as 10 microns to maintain a clean system.

- Corrosion Prevention: Special additives added to the oil would give a protective film on the metal surface to guard against metal oxidation and corrosion. This is especially important where corrosion and eddying by moisture and chemical impurities are factors, especially in marine or chemical-processing industries. For example, synthetic oils having anti-corrosion properties can extend the life of machines by 20-30%.

- Seal Support: Oil supports the sealing action in machines by filling up gaps between components, thus reducing leakage and maintaining pressure. This is crucial in hydraulic systems and compressors where oil majorly dictates the operational integrity. High-viscosity oils enhance sealing action in applications experiencing constant pressure and leakage.

The five main functions presented above highlight an overarching approach toward the improvement of durability, performance, and efficiency in several industrial and mechanical fields by oil as a lubricant.

Lubricating Film and Its Importance

A lubricating film is an abstract concept that defines an extremely thin layer of lubricant existing between two surfaces in relative motion. It acts as a protective layer, preventing direct contact between the two mating surfaces. The film is essential in controlling friction and wear, the damaging agents that cause material degradation and mechanical inefficiency. There are four types of lubricating films: boundary, mixed, hydrodynamic, and elastohydrodynamic, which can be applied depending on specific conditions such as load, speed, and temperature.

Hydrodynamic lubrication, therefore, describes the condition where the surfaces in relative motion are fully separated by a complete film of lubricant, with the applied load being carried much more by the film than the surface-to-surface interaction. Boundary lubrication arises under more severe situations; for example, high pressure, lower speed, and it leaves a molecular layer of lubricant that prevents contact. Note that a few factors influencing the effectiveness of a lubricating film are oil viscosity, surface roughness, and relative speed of motion.

Nano-additives and synthetic formulations are perhaps the best modern trends in lubricating technology, which have been established to maintain and improve film stability and performance. For example, nano-particle additives such as graphene or molybdenum disulfide offer better load-carrying capacity and thermal resistance than conventional lubricants. By maximizing the performance of the lubricating film, these new techniques help to increase the lifecycle of machines, making them energy-efficient and highly reliable in operation.

Conditions of Use

High-Temperature Applications

Design considerations for high-temperature lubrication involve significant challenges and require the use of high-performance lubricants capable of maintaining chemical stability and performing well in extreme conditions:

- Thermal Stability: High-temperature applications entail the need for excellent thermal stability in the lubricants. For instance, synthetic esters and PFPE oils can be used continuously at temperatures above 300°C without being degraded or oxidized considerably.

- Oxidation Resistance: Oxidation will speed up under high temperatures and may cause sludge formation and deposits. With the advent of improved additives like phenolics and amines, antioxidant formulations that are added to the oil prevent or delay their oxidation.

- Viscosity Retention: At high temperatures, it is very important to maintain viscosity to ensure sufficient film strength and protection. Compared to conventional mineral oils, multi-grade synthetic oils with viscosity index improvers performed better in maintaining viscosity under high temperatures.

- Load-Bearing Capacity: Operating temperatures cannot be generalized without considering heavy loads, which require great load-carrying capacity lubricants. Under high pressure and temperature, nano-additives, such as molybdenum disulfide (MoS2) and tungsten disulfide (WS2), enhance the film strength to counteract wear and friction.

- Evaporation Loss: Loss of evaporation shall be kept to a minimum by any lubricant so that consumption is minimized and good lubrication is maintained in high-temperature conditions. The synthetic oils, such as PAO or silicone-based oils, pose a lesser risk of evaporation loss when compared with conventional oils; hence, longer intervals between reapplications are possible.

These properties make it necessary to carefully engineer a lubricant solution for high-temperature industrial applications to guarantee reliability and efficiency.

Extreme Pressure and Continuous Motion

These days, with extreme pressures and continuous motion, the lubrication requirements increase since these present really high mechanical stresses and extremely high temperatures within the machinery. Components operating under these conditions experience accelerated wear, material fatigue, and possible failure unless adequately protected with some particularity. The lubricant has to resist breakdown while creating a thin but tenacious film over the surfaces where the metals are in contact, thus reducing friction and wear.

Extreme pressure (EP) additives, hence, are commonly included in lubricant formulations to combat such situations. These additives may include sulfur-phosphorus compounds, which chemically react with the metal surfaces under such heavy loads and heat to create a thin protective layer, thereby reducing the risk of metal-to-metal contact or damage. Lubricants with high thermal stability and oxidation resistance would also be a perfect match for those continuous-motion applications that operate under heavy loading and occur for long periods.

In my humble opinion, the essentials are that lubrication in a high-pressure environment with continuous motion needs to be tackled with great care. Optimal equipment performance is realized through advanced formulations of EP additives and thermal stabilization, which indirectly increase the service life and lessen maintenance downtime, even under the most punishing operating conditions.

Comparative Analysis: Grease vs Oil

Grease provides the best sealing, contamination control, and longer period of adherence, whereas oil generally is a better heat conductor, acts better in high-speed situations, and is easier to maintain.

|

Aspect |

Grease |

Oil |

|---|---|---|

|

Retention |

Long-lasting |

Flows freely |

|

Thermal Control |

Limited |

Excellent |

|

Debris Handling |

Seals contaminants |

Removes contaminants |

|

Energy Demand |

Higher |

Lower |

|

Upkeep |

Infrequent |

Frequent |

|

Usage |

Heavy-duty, low-speed |

High-speed, high-temp |

|

Eco Impact |

Harder disposal |

Easier disposal |

|

Inspection |

Difficult |

Easy |

|

Expense |

Higher upfront |

Lower upfront |

|

Durability |

Shorter in bearings |

Longer in bearings |

Industries and Applications

Automotive Industry Uses

In the automotive industry, differentiating types of uses of lubricants have come to be used depending upon the specific lubrication purpose of performance, reliability, and life. Five such uses are given below with details and benefits:

- Engine lubrication: Engine oils are essential in reducing friction and wear between moving surfaces in internal combustion engines. Under normal situations, the good engine oils containing viscosity modifiers and detergents ensure proper cooling, without sludge formation, and good fuel efficiency. For example, a fully synthetic oil reduces wear rate by as much as 25% compared to a conventional oil in a high-performance engine.

- Transmission Fluid: Transmission fluids are used to generate less heat and provide smooth shifting of gears in transmission systems, whether manual or automatic. Advanced formulations containing friction modifiers also maintain the optimum performance of the transmissions under various temperature ranges and load conditions. The studies have revealed that if an appropriate transmission fluid is used, the gears can last 30% longer.

- Chassis Lubrication: Greases are used widely for lubricating chassis points such as ball joints, control arms, and suspensions. They prevent corrosion, prevent squeaking, and allow smooth movement. High-performance greases with EP additives for heavy-duty applications can increase service intervals by up to 40%.

- Wheel Bearing Greases: Wheel bearings require greases that can sustain high rotational speeds and temperatures. Synthetic greases with high thermal stability lower frictional losses and extend service intervals. It is established from the field data that premium wheel bearing greases offer load capacities that are 50% higher than the standard options.

- Air conditioning compressor oil: Air conditioning compressor systems in vehicles require special oils for their operation without seizing. These oils lubricate while maintaining compatibility with refrigerants. A properly lubricated compressor reduces energy consumption by 10 to 15%, further improving energy management in present-day automotive systems.

Therefore, all these lubricant uses are important in attaining the highest performance and optimum operational life of an automobile, thus pointing out the crucial role of advanced lubrication solutions in the automotive industry.

Manufacturing Sector Requirements

The manufacturing industry makes unique and stringent demands on lubrication solutions to lend support to high-performance machinery and ensure uninterrupted production. Lubricants in this environment are required to demonstrate high thermal stability, good oxidation resistance, and anti-wear properties to withstand harsh conditions often encountered during industrial applications. For instance, lubricants for heavy machinery engaged in the metal process or textile production need to have very high load-carrying capabilities in order to prevent wear due to the high pressures involved.

Synthetic, polyalphaolefin (PAO), ester, or other highly engineered industrial oils have always outperformed ordinary mineral oils under severe manufacturing conditions because of their superior molecular-level stability and long life. Cleanliness of the lubricant and contamination resistance also matter in CNC machining and precision equipment, where even minute particles might cause aberrations or lead to costly downtimes.

Energy efficiency thereby becomes yet another consideration, as advanced lubricants reduce friction losses in mechanical systems. For example, energy-efficient hydraulic oils reduce power consumption in hydraulic presses by 5%, and high VI oils maintain optimal lubrication film thickness over operating temperature and reduce maintenance intervals with longer equipment lifetime.

The other end of the scale includes food and pharmaceutical manufacture, which must adhere to stringent standards, e.g., ISO 21469, where food-grade lubricants have to be ever so carefully marketed. This demonstrates industry reliance on a very specialized form of lubricant that must balance between just meeting operational demands and being compliant with environmental regulations.

Aerospace and Agriculture Applications

From strategic importance down to specialized needs, the systems industries have always utilized advanced lubrication technologies for maximum efficiency and durability under harsh operational requirements. Below are five crucial applications required in each field requiring specialized lubrication solutions:

- Aerospace applications:

- Jet Engine Lubrication: Synthetic lubricants of extremely high standard find applications in jet engines because extreme temperatures, extremely high speeds, and variations in pressure provide conditions of use that demand the greatest thermal stability and resistance to oxidation. The lubricants may well be usable from 60°F below zero to over 400°F.

- Landing Gear Systems: Greases with special properties are used for wear protection of parts of the landing gear in reliable conditions, under high pressure, and extreme weather conditions. Takeoff, flight, and landing periods must be well lubricated.

- Hydraulic Systems: The fire-resistant hydraulic fluids in use in aerospace hydraulic systems ensure safe operating conditions. These fluids maintain their viscosity even at severe pressure cycles and show high thermal stability.

- Satellite Mechanisms:

- There is a need for space-grade lubricants to carry out deployment and operational functions of satellites, which offer long-term performance in vacuum environments without evaporation or molecular degradation.

- Electrical Connections and Components: Conductive and non-conductive lubricants safeguard electrical connectors against corrosion and fretting wear in aerospace systems, thereby assuring the reliability of avionics over long service life.

- Agriculture Applications:

- Tractor Engines and Transmissions: These multi-functional oils are used for lubricating tractor engines and transmission systems to improve performance and efficiency while reducing downtime of agricultural machinery.

- Harvesting Equipment Bearings: Heavy greases help in protecting bearings under heavy loads and moisture conditions, while uninterrupted harvesting depends on it.

- Irrigation Systems: Corrosion-resistant lubricants are used in pumps and valves of irrigation systems so that water transport remains smooth and systems remain reliable.

- Seeder and Planter Mechanisms: Anti-dust lubricants are used to ensure smooth functioning of seeders and planters, which would prevent blockage and irregular seed distribution.

- Agricultural Drones: Lightweight, low-friction synthetic oils ensure effective operation and reliability of drones used in crop monitoring and pesticide spraying.

These applications underscore the role of custom lubrication technology in maximizing machinery functionality and lifespan in both aerospace and agricultural environments.

Choosing Between Grease and Oil

Factors to Consider

There are many technical factors one must consider before deciding to use grease or oil for a particular lubrication. First and foremost is deciding the temperature range. Oil, being fluid, generally gives better performance in higher temperature environments where dissipation of heat is crucial. Grease is usually called for where adhesion to the surface needs to be stronger, as in those scenarios involving low speed and high load.

The next criteria concern the design of the lubrication system. Lubrication systems, except manual ones, will generally prefer the use of oil for ease of delivery to different parts; grease will have its applications when this comes down to manual application to certain discrete components. Also, conditions concerning exposure to the environment play their role-because in such cases, grease would be the best fit to keep out contamination: dust, water, and debris, potentially harmful to more exposed machinery.

Load conditions equally matter. Heavy loads or extreme contact pressures require greases, for greases-their thicker nature constitutes a protective barrier. oil, with its low viscosity, is best suited to slow friction needs under high-speed operation and light load. Compatibility with seals and materials, as well as chemical interactions, should be explored to avoid premature wear or failure of operation.

Considering all these factors in light of the particular machinery and its working environment can offer a good framework for the intelligent selection in an attempt to improve efficiency and durability across a broad array of industrial applications.

Optimal Scenarios for Each Lubricant

By specific operating, it is imperative to choose a lubricant with adequate properties to provide the best performance. Among synthetic types and given high-temperature conditions, PAO- or ester-based lubricants are very much ideal because the thermal stability and oxidation resistance of these substances are superior. They do not lose viscosity or anti-wear ability when exposed to very high temperatures and thus should be used for industrial machinery subjected to continuous cycles of high heat.

In contrast, mineral-based lubricants are better in cases where the main consideration is cost, and environmental conditions do not subject the lubricant to extreme temperature or load. Ever available and having good compatibility with a large number of materials, these lubricants work in fairly standard conditions.

For applications that require extreme-pressure resistance, such as heavy-load industrial gears or high-impact machinery, a lubricating oil with EP additives is a must. In these lubricants, the molybdenum disulfide and sulfur-phosphorus additives react and form a chemical protective layer, thereby limiting metal-to-metal contact and wear under heavy pressure.

Rust- and corrosion-resistant greases are primarily designed for equipment functioning under humid or wet conditions. These greases typically contain thickeners such as lithium complex or calcium sulfonate, which offer excellent adhesion as well as resistance to water washout, thus extending the life of equipment in marine applications or wastewater treatment facilities.

The awareness of these optimal environments, along with chemical compatibility, equipment design, and maintenance requirements, will allow for the selection of lubricants that could give the best service with the least system wear and downtime.

Long-Term Maintenance Benefits

Using selected high-performance lubricants strategically for maintenance translates to ensuring operational inefficiencies, deterioration of parts, and failures in systems are greatly minimized. Mainly, this increases the reliability of the plant and also reduces costs while increasing system longevity. Here are the five critical advantages of using quality top-grade lubricants in long-term maintenance:

- Increased Equipment Life: High-performance lubricants act to minimize friction and wear, leading to a lack of component failures and therefore to the extension of equipment life. Well-lubricated systems can experience an increase of about 20-30% in service life as compared to systems lubricated with standard-grade lubricants.

- Reduced Downtime: Optimally designed lubricants seldom cause equipment failures and maintenance, thus minimizing downtime. For industries working around the clock, this means operational downtimes can be reduced by about 15% annually.

- Energy Costs Reductions: These advanced lubricants lower the energy used as a result of a reduction in internal machinery’s friction. Industry data suggests an energy saving of about 5-10% in systems implementing advanced lubrication technology.

- Corrosion Protection and Contaminant Interference Control: These lubricants have additives that prevent corrosion while they minimize harm from contaminants such as dirt, moisture, and chemicals. This reduces the potential for progressive damage, especially in harsh environments like offshore rigs and chemical plants.

- Maintenance Cost Savings: Helps to gain long-term cost savings by reducing the frequency at which part replacements and downtime occur. Case studies have shown up to a 20% reduction in maintenance budgets by using high-grade lubricants coupled with proactive monitoring.

The practical approach aims for operational excellence and sustainability to guarantee that the machine is consistent in boosting its capability.

Frequently Asked Questions (FAQ)

Q: What is the fundamental difference between grease and oil?

A: The fundamental difference between grease and oil lies in their composition and consistency. Grease is a semi-solid lubricant that contains a thickening agent and base oil, whereas oil is a liquid lubricant primarily composed of base oil. This distinction affects their application and effectiveness in various lubrication scenarios.

Q: In what situations is grease better than oil?

A: Grease is better than oil in situations where long-lasting lubrication is required, such as in sealed or enclosed environments. Its thick consistency helps it stay in place, reducing the need for frequent replenishment and providing effective lubrication for moving parts that may experience heat generation.

Q: What are the common applications for oil used in machinery?

A: Oil used in machinery is commonly applied in high-speed machinery and variable-speed operations where fluidity and low viscosity are essential. Oil lubricants provide effective lubrication by reducing frictional heat and allowing for smooth operation, especially in applications subject to frequent movement or high temperatures.

Q: How do thickening agents affect grease consistency?

A: Thickening agents play a crucial role in determining grease consistency. They help to thicken the base oil, resulting in a gel-like texture that can maintain its form under pressure and temperature variations. This property makes grease suitable for applications where stability and retention are important.

Q: What are the contamination risks associated with grease and oil?

A: Both grease and oil are susceptible to contamination risks, such as the ingress of harmful contaminants. However, grease generally has a lower risk of contamination due to its thicker consistency, which helps it resist the infiltration of dirt and debris compared to oil, which can be more easily contaminated due to its fluid nature.

Q: Can oil be used in small spaces like grease?

A: While oil can be used in small spaces, it typically does not provide the same level of retention as grease. Grease is designed to stay in place, making it more suitable for confined areas where constant lubrication is needed without the risk of leakage, whereas oil may require more frequent application.

Q: What factors should be considered when selecting the appropriate lubricant?

A: When selecting the appropriate lubricant, factors such as the operational environment, temperature, load conditions, and the type of machinery should be considered. The difference between grease and oil can greatly influence the choice, especially when evaluating the need for long-lasting lubrication versus fluidity and ease of application.

Q: What role do solid additives play in grease?

A: Solid additives, such as graphite, enhance the performance of grease by improving its lubricating properties and reducing wear on components. These additives can provide additional protection against friction and heat generation, making grease more effective in demanding applications where high viscosity is required.

Q: How does the viscosity of oil impact lubrication?

A: The viscosity of oil impacts lubrication by determining how well it can flow and reduce friction between moving parts. Oils with lower viscosity are better for high-speed machinery as they can easily circulate, while thicker oils provide better protection under heavy loads. Understanding the difference between oil viscosities and formulations is essential for optimal performance.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8