Ball Screw Support: Understanding Systems, Applications, and Innovations

Precision, efficiency, and durability are the cornerstones of modern machine design, and at the heart of many high-performance systems lies the ball screw support. This critical component plays a pivotal role in converting rotational motion into linear motion, enabling the smooth and accurate operation of various machinery across industries. From advanced manufacturing equipment to aerospace engineering and robotics, ball screw supports are integral to achieving optimal mechanical performance. In this article, we will explore the intricate workings of ball screw systems, examine their diverse applications, and uncover the latest innovations shaping their future. Whether you’re an engineer, a researcher, or a machine design enthusiast, this comprehensive guide will provide valuable insights into one of the most essential components of today’s cutting-edge mechanical systems.

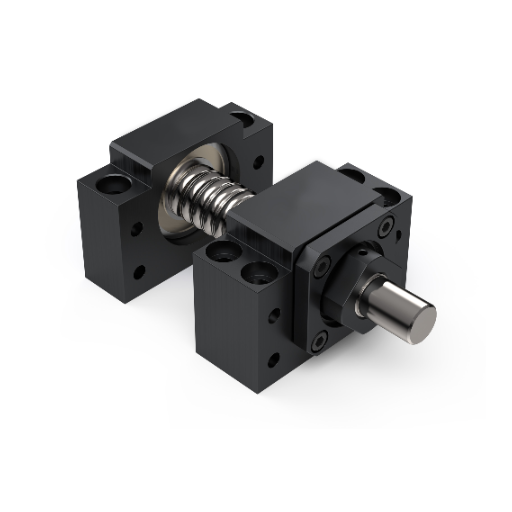

Types of Ball Screw Support

Fixed Support Systems

Fixed support systems are paramount for the precise alignment and stabilisation of ball screw assemblies under different working conditions. These support systems give rigid anchoring on one or both ends of the ball screw, restricting axial and radial translations and maintaining the required preload. Usually, fixed supports come equipped with bearings of a high load capacity, designed to withstand thrust loads and transmit forces with full accuracy. The configuration is profoundly effective in minimising deflection, especially under high speeds or heavily loaded operations, thus providing for their good performance and prolonged life.

Two typical arrangements of fixed support systems exist: single-end fixed and double-end fixed. In the single-end fixed configuration, the ball screw is rigidly anchored at one end and allowed to move freely or simply be supported at the other end. This type of configuration is generally used for applications with relatively moderate-to-low loads and short screw lengths. The double-end fixed configuration firmly fixes the ball screw at both ends. This configuration is used for precision systems that demand maximum rigidity, for example, CNC machines and robotic actuators, where minute deflections could translate into a loss of accuracy.

Choosing the right kind of fixed support system depends on things such as load requirements, operating speed, and the particular application. When compared to inferior kinds of materials, the use of high-grade materials and modern bearing technologies will make the supports very reliable. A proper installation procedure and periodic maintenance ensure that the fixed support systems will always render optimum service, thus preventing misalignment and wear as time goes by.

Simple Support Systems

Simple support systems are mechanical and structural means for compensating minimum foundation support of loads. Such systems typically allow free rotations along horizontal refraction while preventing vertical translation. Most applications of simple support systems are beams, bridges, or other load-bearing structures that need to be effectively dampened from bending or deflecting.

The primary advantage of simple support systems is their flexibility and ease of installation. They can be modified to suit any operating conditions by selecting different materials and designs for the loads, span lengths, and environmental conditions. For example, steel and reinforced concrete are mainly favored for their strengths under different stress states and their durability.

In any case, to get the best performance from simple support systems, proper planning must be put in place. An improper installation or even one that is not maintained will lead to an excess of deflections beyond permissible limits, thus endangering the structural integrity. Regular inspection and proper alignment during installation should be ensured so that the system can continue to fulfill its functional integrity. These measures will prevent deformation or failures due to dynamic loading.

Floating Support Systems

Floating support systems are specialized structural solutions meant to counterbalance loads while allowing minute movements within the system. Generally, these systems find use where flexibility and susceptibility to any external force becomes critical, such as in marine and offshore engineering, bridges, or high-rise buildings affected by seismic disturbances. Floating supports function as a means of ensuring stability while allowing thermal expansion, vibrations, and lateral shifts. In other words, these systems guarantee the overall structural integrity.

For adequate working, these systems require precision-engineered components such as elastomeric bearings, sliding mechanisms, or even hydraulic damping units that absorb energy and dissipate stresses evenly. Selecting proper materials is, of course, very important; corrosion-resistant alloys or polymer composites are often chosen for their durability in extreme environmental conditions. With advanced techniques in modeling, such as Finite Element Analysis (FEA), one can predict stresses and optimize the layout for the safest design possible.

Installation and maintenance are equally vital to the proper operation of floating support systems. During installation, the alignment must conform to strict tolerances to function appropriately under load. Regularly, one should monitor the system for signs indicating wear, deformation, or signs of material fatigue to decide in time about any necessary measures, i.e., adjustment or replacement of components. Also, an integrated long-term resistance monitoring system of floating supports can accumulate relevant data on load behavior and interactions with the environment. This data can then be used for proactive maintenance planning.

Applications of Ball Screw Support in Various Industries

Manufacturing Sector

The conception of ball screw supports in machinery is an extremely precise and delicate task that is fully necessary in CNC machines, robotic arms, and automated assembly lines; enabling smooth linear motion ensures absolute precision and repeatability. For example, to bring numerous designs to reality, with either cutting, drilling, or engraving that requires positional control of the utmost precision, one needs to have a ball screw support in a machining center.

The improvement of performance and durability in ball screw supports has significantly followed the development of material and lubrication technology. For instance, the use of wear-resistant coatings together with self-lubrication mechanisms assured longer life periods with far less frequent maintenance afterwards. Meanwhile, establishing real-time monitoring systems in manufacturing equipment allows the operator to observe performance, including motion accuracy, torque, and heat generation, among others. Thus, these experiences may be utilized to improve operational efficiency and predict any impending breakdowns.

Energy consumption in the manufacturing setup is reduced by 20-30% with the use of high-efficiency ball screw systems in place of traditional lead screws or pneumatic actuators, according to empirical data. Thus, they represent an environmentally sustainable alternative and a cost-saving one. This is also further supported by the recent advancement in Industry 4.0 technologies in the manufacturing sector, as these technologies continue to improve the operational front in terms of automation and smart factory frameworks.

Robotics Applications

Ball-screw systems stand as principal components in contemporary robotics because they offer highly precise and efficient operations. The systems enable an extremely accurate linear-motion path, which is crucial for complex jobs that involve serious handling steps, such as semiconductor assembly, medical device manufacturing, or laboratory automation. Ball screws maintain better position repeatability in the micrometer range as compared to pneumatic or hydraulic systems, giving utmost consistency in complex operations developed for long hours. In emerging robotic designs of Industry 4.0 environments, designers meet increasing demands from ball screws. Good load-bearing characteristics along with minimal friction render these well-suited for manipulative and dexterous robotic arms. Other factors contributing to the design are lower wear and lower maintenance costs, eventually leading to reliability in the long run.

Recent innovations have upgraded ball screw systems with coatings and treatments to enhance wear resistance or facilitate speed increases without sacrificing accuracy. These progressions have put ball screw systems among the must-have aids in classic manufacturing robotics and state-of-the-art autonomous systems alike. On top of it, the adoption of collaborative robots (cobots) also profited from the increased use of ball screws, as their low noise and smooth operation fulfill the human safety and ergonomic criteria concerning human-robot collaborations.

The integration of ball screw technology in the design of robots allows engineers to venture into new areas of automation while upholding the goals of precision, energy efficiency, and adaptability.

Aerospace Industry Utilization

The aerospace industry is greatly dependent on advanced engineering design to guarantee performance, reliability, and safety under numerous extreme conditions. Still, the sophisticated motion control ecosystem concerning the design and manufacture of actuator systems in aerospace applications considers ball screws as one of the critical flight elements for any flight intervention. These sophisticated devices convert rotating motion into linear-motion precision, thereby enabling precision for adjusting flap and slat displacement, landing gear positioning, and satellite positioning.

Ball screw assemblies for aerospace purposes are mostly designed from high-strength materials against corrosion, with very high load capacity to withstand extreme conditions at very high altitudes or in space dates. The design demands hardly any backlash, offering better efficiency and the most consistent, reliable operation even when facing massive extremes of temperature gradients and vibrations. In addition to traditional designs, newer coatings and lubrication technologies have enhanced their wear properties and brought down the maintenance requirements, thus rendering the long-term operational efficiency of ball screws a vital application for modern aerospace systems.

With the Airbus-DASA initiative and the wide thrust towards weight reduction and energy efficiency in aerospace design, ball screws get increased attention. They provide a much lighter, compact solution compared to conventional systems like hydraulic actuators, creating fuel savings and a greener environment. This very trend is common in the industry of emissions reduction and the aircraft for performance optimization main arena of next-generation aerospace engineering innovations.

Benefits of Using Ball Screw Support Systems

Enhanced Efficiency and Performance

Ball screw support systems are critical in enhancing efficiency and operational capabilities of mechanical and aerospace settings. By decreasing frictional forces between moving parts, the motion becomes very smooth and with much higher precision; hence, it promotes the entire end-function of a machine. Similarly, ball screws suffer lesser energy losses while transmitting power to the load, making them suitable where energy conservation takes precedence.

In my own words, ball screw mechanisms lend to enhanced functionality by way of reliable performance over an extended period. Thereby, the design distributes loads relatively evenly and helps reduce the wear on components to an extent, resulting in a longer life for the system. Reliability also cuts on maintenance, downtime, and operational costs.

My strong belief would be that ball screw support systems making use of their capabilities greatly aids in addressing modern engineering challenges. The provision for accuracy, power efficiency, and toughness in these systems makes them indispensable in aerospace, robotic tasks, and production. In this regard, the ball screw continues to be the design of choice in applications requiring high output and sustainable performance.

Improved Precision in Motion Control

When it comes to modern engineering, motion control is a matter of perfect precision, especially in areas such as robotics, aerospace, and advanced manufacturing. Their least friction and energy-efficient performance allow ball screw systems to deliver the highest accuracy in accomplishing linear motion tasks. Motion control systems on high-precision components can realize movements down to a few microns with very little discrepancy, thereby allowing the execution of tasks that require tight tolerances and highly accurate positioning. Such developments are therefore of paramount importance in industries where operational life is defined by the ability to produce products with unwavering precision.

Ball screw systems work in a manner that contributes to their great precision. They convert rotational motion into linear movement with almost no backlash, with preloaded ball bearings providing minimal mechanical play that can introduce errors into an operation. In addition, materials and coatings have been improved with time to ensure the durability and thermal stability of the components in ball screws so that their performance remains the same even under the most arduous operating conditions. The development of advances in computer-aided design and manufacturing (CAD/CAM) has further enhanced the precision-critical tasks by improving the alignment and configuration of these systems.

With the integration of sensors and feedback loops, ball screws just got better for motion controls. For example, servo systems use positional feedback in real-time to make dynamic adjustments to movements so that any deviation is corrected within a millisecond. This responsiveness is allowing better coordination of robotic applications, machining CNC in flawless execution, and increased dependability of hardware for space exploration. So, the ball screw system is not just one ingenious creation but rather a vital step in the advancement of precision in a variety of technical fields.

Durability and Longevity of Systems

The durability and longevity of mechanical and electromechanical systems are viewed as measures of their efficiency and return on investment in areas where precision and dependability constitute the foundation of work. Consider ball screws, for example: these systems are designed to operate through countless cycles under very high loads without undue wear or degradation. The high-performance capabilities of these systems occur largely as a function of the materials used in their construction instance, high carbon steels or alloy steels, heat-treated to increase hardness and resistance to fatigue. Meanwhile, coatings of titanium nitride or black oxide may be applied to protect against corrosion and wear so that the components can be worked to end longer in harsh environments.

In terms of design, load distribution optimization and friction reduction innovations are major contributors to life extension. Examples of these include preloaded ball screws, which are engineered such that clearances are minimized to reduce backlash while allowing load forces to be distributed evenly at all contact points, thereby eliminating or vastly reducing localized stress concentrations. This increases mechanical efficiency and delays wear and tear. Additionally, lubrication systems, either automatic or manual, are installed to reduce friction and heat generation, which are some of the leading causes of component failure when the system is working on a long-term basis.

There is also a big push for the durability of advanced systems through aggressive testing and quality control schemes. Accelerated life tests (ALT), non-destructive testing (NDT), and real-time condition monitoring technology are being increasingly employed by the industry to estimate wear patterns and identify potential failures before actual failures occur. Sensor-based condition monitoring systems, for example, may monitor vibration, thermal behaviors, and acoustic emissions of a process and identify deviations from acceptable or normal operating conditions, thereby initiating actions, either manual or automatic, to prevent further degradation. Such innovations ensure systems go well beyond their promised life, thereby cutting down on downtime and raising productivity levels across the spectrum from aerospace to industrial automation. Interactions between materials science advancements, innovative engineering, and proactive maintenance methodologies continue to guide the evolution of durable, long-life systems in the current high-tech world.

Maintenance Tips for Ball Screw Support

Regular Inspection and Lubrication

The frequent inspection and lubrication of ball screw support systems are required to ensure the systems are operating at top efficiency, and to extend their lives. The inspection should be aimed at pinpointing any wear, contamination, or misalignment. If you notice anything unusual, like strange noises, irregular movement, or vibrations coming from the machine during its operation, these can be warning signs that the machine is in its initial stages of depreciation. The first step in the procedure is to inspect the surface condition of the ball screw. Check for scratches or denting on the surface, and if wear is excessive, improper contacting patterns must exist between the ball nuts and the screw shaft. Meanwhile, environmental factors such as dust, moisture, or chemical exposure should be considered, for these naturally speed up wear and tear of critical components.

Lubrication represents a prerequisite for keeping the ball screw mechanism in good working order. The lubricant acts by reducing friction and heat production as well as preventing corrosion. At all times, only the lubricants recommended by manufacturers must be employed, as these lubricants are generally formulated to suit the thermal characteristics, speed, and load requirements peculiar to the ball screw mechanism. Moreover, the proper quantity of lubricant should be applied. Too little lubrication, and friction will increase, resulting in wear. Too much could cause leakage or attract contaminants. An automated lubrication system, if introduced, will guarantee consistent execution of lubrication cycles and the quantity to be dispensed.

Prevention of unintentional downtime can be substantially enhanced if inspections are done regularly and an effective lubrication strategy is adopted. One recent study indicates that a scheduled maintenance program in combination with real-time condition monitoring techniques can increase the average service lifetime of ball screw assemblies by 25%. These solutions maximize the performance reliability of machinery and reduce long-run costs. Hence, practices such as vibration analysis and thermal imaging will complement usual inspection and lubrication practices in a more timely, condition-based maintenance style. Thus, the days ahead ensure the efficient performance of your ball screw support systems in highly demanding applications.

Adjusting Preload for Optimal Performance

Setting proper preload is one of the most important measures for the achievement of maximum performance from ball screw assemblies. The term preload refers to the intentional internal load on a ball screw mechanism caused by the balls being slightly oversize for the raceway, resulting in less clearance and increased rigidity. When preloads are appropriately applied, the backlash is eliminated, and mechanical stiffness should be increased to improve positional accuracy, which is critical for CNC machinery, robotics, and semiconductor manufacturing. However, if there is improper adjustment, there could be too much preload or too little. This will cause premature wear, overheating, and loss of efficiency, which basically degrades the life span of the system.

Preload adjustments must be made upon differing operational requirements and load conditions of the machine. For working at high speeds with huge dynamic forces, the preload should be less to reduce friction and heat build-up. On the other hand, for applications requiring high precision and heavy loads, a relatively heavy preloading is appropriate to enhance rigidity and reduce deflection under stress. Advanced systems choose from preloads qualified as “light”, “medium”, and “heavy” by the manufacturers in order to meet graded performance requirements. The usage of thermal imaging during machine operation can reveal potential hotspots caused by the excess preload and therefore gives useful information for real-time adjustments.

These technologies go further for optimizing preload adjustment by integrating digital monitoring systems that keep track of performance in real time. These sensors are installed across the assembly, measuring temperature, vibration, and axial displacement, thereby providing meaningful information from which to derive preload adjustments commensurate with the current operating environment. By coupling such innovations with predictive maintenance models, the manufacturer virtually guarantees minimum downtime and maximum reliability. It is through meticulous attention to the subject of preload that machinery operators attain a symbiotic balance of efficiency, durability, and precision in order to meet modern-day industrial applications requiring the highest level of rigor.

Identifying and Addressing Wear and Tear

Wear and tear in machinery occurs because of continued use, operation through material fatigue, friction, and environmental factors such as comings and goings in temperature or exposure to contaminants. Recognizing wear patterns necessitates a variety of approaches, which include both traditional inspection methods and cutting-edge technologies. These include ultrasonic vibration analysis, thermal imaging, and spectroscopic oil analysis, which can exactly identify degradation points.

Corrective actions for wear involve maintenance strategies directed toward the identified cause. Improper lubrication, which is the most common cause of wear, can be rectified through an automatic lubrication system that always maintains the optimal film thickness of lubricant between two moving components. Further improvement of component life can be achieved by applying wear-resistant coatings or by the use of advanced composite materials.

In this respect, to make it happen more efficiently, the implementation of real-time data monitoring systems facilitated by machine learning algorithms is fast becoming an industry standard. Such systems analyze operationaldata to anticipate trends in wear and prescribe timely corrective actions, thus preventing unscheduled downtimes and thereby extending the asset lifecycle.

Innovations in Ball Screw Support Technology

Advanced Materials and Designs

The emphasis on materials for ball screw support tracks enhances performance and durability within precision motion systems. High-strength alloys like titanium and aerospace-grade steel give these support tracks enhanced load-bearing capabilities and resist environmental stresses such as corrosion and fatigue. The introduction of ceramic materials reduces friction coefficients substantially, allowing for smoother and more efficient operations when noise and temperature are high.

Innovative designs further optimize this technology by altering the contact geometry and preventing stress concentration at critical points. For example, helical contact patterns and preloaded nut assemblies equitably distribute loads, working to reduce wear and improve mechanical accuracy over time. The efficiency of this system is boosted with dry-lubrication coatings that reduce dependency on conventional lubrication methods.

With these technological approaches, manufacturers achieve higher levels of operational precision alongside reduced maintenance and increased lifespan, keeping advanced materials and design practices relevant to next-generation ball screw systems.

Integration of Smart Sensors

The integration of smart sensors into ball screw systems marks a major upgrade in mechatronic design, increasing the possibilities for monitoring, predicting, and optimizing performances. These sensors gather real-time data on vital signs like temperature, vibration, axial load, or even the quantity of residual lubricant. Such precise feedback builds the basis for predictive maintenance, which ensures that any possible issues with increased friction or misalignment may be handled long before they develop into catastrophic system failure. Smart sensors incorporate embedded microelectronics that, depending on design, communicate data to a central monitoring station or cloud-based solution for enhanced analytics and decision-making.

By observing these sensors, manufacturers and operators could assess trending performances over time to identify opportunities for further improvement. For example, deviations in monitored data can indicate a premature mechanical wear or deterioration of lubrication. This kind of insight allows for intervening only when necessary, thus reducing unscheduled downtime and extending the lifespan of the system. In addition, these sensors are compatible with IIoT platforms, ensuring seamless integration into enterprise-level automated frameworks where decisions are made based on data.

Combining complex sensor data with AI analytics can produce self-regulating systems that adjust themselves according to changing operational situations. This synthesis therefore outperforms regular maintenance schedules in reliability and adheres to current advancements in manufacturing that emphasize sustainable, efficient, and accurate production. Thus, smart sensors convert basic ball screw systems into intelligent self-monitoring units that are less burdened by the requirements of forthcoming machines.

Trends in Automation and CNC Applications

The development of automation and CNC applications revolves around the amalgamation of smarter technologies to provide increased productivity, precision, and sustainability. One of the prominent trends is using AI and ML algorithms for predictive maintenance and process optimization. These methods allow CNC systems to observe operational data by themselves, predict possible failures, and set the manually on the fly, minimizing downtime and thus maximizing efficiency.

The other remarkable trend is IIoT devices that can create connectivity among machines, controllers, and cloud platforms. Such systems ensure uninterrupted data flow such that manufacturers can monitor data from production lines remotely and initiate measures based on this data to enhance throughput and quality. The connectivity between the ecosystem gets even better through edge computing, wherein the computational power moves closer to the data source, thus reducing latency and allowing for real-time data processing.

Another emergent aspect in CNC is that of sustainability. In this regard, the new CNC systems are increasingly energy-efficient in design and employ regenerative braking mechanisms to reduce energy consumption. Also, one very active area is the employment of digital twin technologies that help manufacturers in developing a virtual model of the physical processes and use simulation for operations and their optimization without any wastage of materials.

Frequently Asked Questions (FAQ)

Q: What is ball screw support?

A: Ball screw support refers to the system that stabilizes and facilitates the movement of a ball screw assembly. It provides necessary rigidity and ensures that the screw shaft can operate efficiently within its intended applications, such as in CNC machine tools.

Q: How do support bearings function in a ball screw assembly?

A: Support bearings are critical components in a ball screw assembly. They help maintain the alignment of the screw shaft, support axial loads, and reduce friction during operation. Proper installation of these bearings enhances the service life and performance of the ball screw support.

Q: What factors affect the critical speed of a ball screw support?

A: The critical speed of a ball screw support is influenced by several factors, including the length of the screw, diameter, and material properties. Operating at or above this speed can lead to resonance, which may compromise the performance and longevity of the screw assembly.

Q: How can I specify the correct ball screw support for my application?

A: To specify the correct ball screw support, consider the load requirements, the length of the screw, maximum speed, and axial direction of movement. Additionally, evaluate the type of mounting and the desired rigidity, as these parameters will affect the overall performance of the screw applications.

Q: What are the main components of a ball screw support assembly?

A: A typical ball screw support assembly comprises the screw shaft, nut, support bearings, and locking mechanisms such as lock nuts. Each component plays a vital role in ensuring smooth operation and maintaining the concentricity of the system.

Q: Can ball screw support systems handle compressive forces?

A: Yes, ball screw support systems are designed to handle compressive forces effectively. The support bearings and the screw nut work together to distribute loads evenly, allowing for efficient operation under various conditions, including high-performance applications.

Q: What is the impact of temperature on ball screw support performance?

A: Temperature can significantly affect the performance of ball screw support. Changes in temperature can lead to thermal expansion, potentially causing looseness in the assembly. It is essential to account for temperature variations during the design phase to maintain optimal performance.

Q: How do roller screws compare to traditional ball screw supports?

A: Roller screws, like ball screw supports, provide precision motion control but with higher load capacities and improved efficiency. They utilize rolling elements to reduce friction, resulting in longer service life and better performance in demanding applications.

Q: What role do angular contact bearings play in ball screw support?

A: Angular contact bearings are crucial in ball screw support systems as they allow for handling both radial and axial loads. This dual-load capability enhances the overall stability and performance of the assembly, particularly in high-speed and precision applications.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8