Automotive Oil Seals: A Comprehensive Guide to Oil Seals and Shaft Seals

For efficiency maintenance, and longevity of your vehicle, even the smallest components matter. An automotive oil seal and shaft seal are the unsung heroes, preventing leaks, protecting internal components, and assisting in performance. Whether a car enthusiast, a professional mechanic, or just someone interested in learning more about their vehicle, this guide walks you through the basics of oil and shaft seals, from their purpose and operation to the materials that make them tough. So keep reading to learn the interesting facts about these crucial components and how they keep your engine running smoothly.

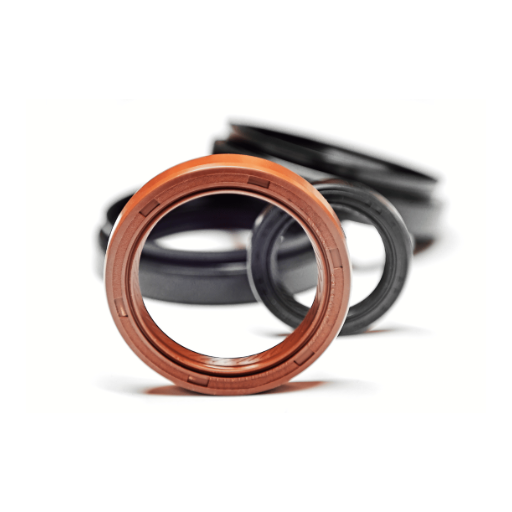

Understanding Oil Seals

Purpose and Function of Oil Seals

An oil seal functions as a barrier that prevents leakage of oil and ingress of contaminants. They are installed between two components to make sure that lubricants such as oil stay within the mechanical system while external contaminants such as dirt, dust, or moisture are kept out. This sealing operation ensures efficient operation of machinery with the least wear on internal components.

The other important activity of oil seals is to prevent contaminant-induced damage to internal mechanisms. For instance, in the case of engines and gearboxes, oil seals ensure proper lubrication by stopping leaks that could otherwise cause overheating and increased friction, leading to equipment failure. It reaches further into attaining optimal performance and extending the service life of mechanical systems by preserving the equipment from being compromised.

They also operate to ensure optimal energy efficiency. From an energy-loss point of view, ineffective sealing could create friction or abnormal lubrication, resulting in so much energy waste. An energy-conscious seal would minimize all of these unwanted side effects, cutting down costs on extra maintenance and frequent repairs. They have significant importance in the well-being of mechanical integrity and operational sustainability, making oil seals indispensable in a plethora of industries.

How Oil Seals Prevent Fluid Leakage

Oil seals put a stop to fluid leakage by forming a tight barrier between components contained in an assembly or machinery. They are custom-made to prevent fluids such as oil to grease from leaking out of the assembly and dirt or dust particles from entering. If the oil seal is able to maintain a tight seal, then the rest of the lubrication process is not compromised, which is critical for the best functionality and durability of the machinery components.

The actual sealing is done by a mixture of design features. The main sealing element, usually made of elastomer or similar flexible materials, fits closely around the rotating shaft to minimize gaps. Oil seals would generally have a metal casing or a reinforced outer structure to provide rigidity and ensure correct alignment during operation. Given the precision of these components, fluids cannot escape even if said fluids are moving at an extraordinary velocity or are under tremendous pressure.

Aside from preventing fluid from leaking, this also helps the system’s effectiveness by lessening the wear and tear on mechanical parts. From oil seals, components maintain the lubrication, which reduces friction and the chances of overheating. They are key to stopping leakage; hence, oil seals ensure that the machining is dependable and can last longer, making them an essential part in both industrial and automotive applications.

Protecting Internal Components from Contaminants

Oil seals usually keep contaminants like dust, dirt, and debris away from the internal apparatus. Should these contaminants enter mechanical systems, they would cause deterioration and lead to loss of efficiency and complete failure of the system. By providing a strong barrier, oil seals prevent contamination and ensure that only the fluids required by the system exist inside.

Contaminants cause the wearing and tearing over time, leading to the machinery not providing smooth operations. The oil seal prevents this from developing and thereby prolongs engine life. For example, dirt and abrasives can scrape against the interior parts, resulting in wear, abrasion, or pitting; by keeping these contaminants at bay, oil seals prevent unnecessary damage and promote reliability in both industrial and automotive systems.

In addition, oil seals exclude contaminants do supporting system efficacy. Smooth motion and efficiency of mechanical processes can only be guaranteed when they are in clean, uncontaminated environments. Such reliability minimizes the need for frequent maintenance checks and brings down the number of downtimes, hence, at least the cost of maintenance. That makes them crucial in enhancing the durability and operational efficacy of machines.

Types of Oil Seals

Rotary Shaft Seals

Rotary shaft seals act as lubricant retainers while preventing the entry of impurities inside the rotating machinery. These seals protect different applications ranging from an automotive engine to pumps or compressors in industries. Generally, these rotary shaft seals may be made from a mixture of high-performance materials such as nitrile rubber, silicone, or fluoropolymer, guaranteeing they can withstand variations in temperature, pressure, and chemical exposure.

Modern-day rotary shaft seals use state-of-the-art designs that attempt to solve very specific running scenarios. For example, seals with hydrodynamic patterns on their lips improve lubrication by redistributing the film so as to minimize wear and friction. Furthermore, another design is with double-lip configurations that improve oil retention and the exclusion of contaminants, thereby enhancing performance in harsh working environments.

Developments in rotary shaft seal technology also focus on increasing energy efficiency: friction equals less wear and less heat generation, thereby extending service life and reducing maintenance costs. Being ever-evolving, these improvements make a rotary shaft seal a necessity in modern-day machinery to ensure the best possible performance and reliability of the system.

Hydraulic Seals

Hydraulic seals are components in a hydraulic system designed mainly to prevent fluid leakage and gain pressure within the system for maximum efficiency. Such seals are usually made from polyurethane, rubber, or PTFE to withstand great pressure and extreme temperatures. The evolution of hydraulic seal technology sought better wear resistance, reduced friction, and the ability to sustain high stress even in problematic applications.

Modern seals are produced to accommodate individual needs-for example, rod seals, piston seals, and wiper seals, each having unique challenges in the industry. For heavy equipment, therefore, hydraulic seals have to withstand tremendously harsh forces and cycles, so materials innovation is key to assuring reliability. Reinforced seal systems implementation is now commonplace to give systems better efficiency at high speeds and high pressures.

The advances made in hydraulic seals improve energy efficiency as fluid loss is reduced and less energy is required to keep the system pressure. These improvements have put hydraulic seals in a crucial position in industries such as construction, aerospace, manufacturing, and automotive, where accuracy and top-notch performance matter. Hydraulic seals are, thus, an ever-evolving item with technological improvements pushing them to become more efficient, sustainable, and durable.

O-Ring Seals and Their Applications

The versatility and universality of the O-ring seal make it one of the most widely used sealing systems in various industries. Its simple operation offers it reliability in providing seal solutions for dynamic and static sealing. Typical materials include elastomers, silicones, and fluorocarbon-type polymers, which render O-ring seals good resistance against pressure, temperature, and chemical exposure. Here are five or so common applications for O-ring seals:

- Hydraulic Systems: Stanch O-ring seals prevent fluid leakage and maintain system pressure within hydraulic cylinders and pumps. Their critical nature in maintaining pressure and wear has made them indispensable in these systems.

- Aerospace Industries: The aerospace industry employs O-ring seals in a manner that assures the safety and efficiency of aircraft engines, fuel systems, and landing gear arrangements. Materials in the aerospace industries are often specified to meet extreme temperature and pressure range requirements.

- Automobile Sector: O-rings are found in various automotive components, including engine systems, fuel injectors, air conditioning systems, and transmission assemblies. They provide sealing in adverse conditions under high heat and chemical exposure.

- Medical Equipment: High-performance O-ring seals for equipment such as pumps, valves, and seals for surgical and diagnostic equipment must meet sanitation and chemical resistance standards paramount for the medical field.

- Oil and Gas Industry: O-ring seals in offshore platforms, pipelines, and refineries are designed to withstand harsh environments with corrosive fluids and high pressure to guarantee operational reliability and safety.

These applications exhibit the demand for the solutions O-rings provide in varied industries as a testament to their usefulness and versatility.

Signs of Oil Seal Wear and Failure

Identifying Common Leak Indicators

A timely detection of oil seal wear and failure can save a lot of money that would otherwise go into repairing the equipment and into downtime losses. With oil or fluid leaks near the seal or connected components being one of the most common signs of a problem, depending on the severity of the problem, these daily leaks could appear as tiny drips, as a handsome accumulation around the seal, or even as an oil pond. Discoloration or residue buildup near a seal could also be a sign that the oil is either escaping or that contaminants are compromising the system.

The other common symptom of oil seal wear is the occurrence of abnormal noises and vibrations during the operation of the equipment. Wear or damage to a seal might have led to misalignment or increased friction, hence mechanical noise, or irregular movements in the functioning of some other body. It may also see a temperature rise with increasing friction, so temperature measurement of associated systems may be used as another tool for diagnosis. A stringent practice of inspections during the maintenance routine must be put in place to spot the subtle changes before they become destructively evident.

Reduction in performance levels of machinery or equipment may also suggest oil seal failure. Failure of a seal to perform its intended function of preventing leakages would allow contaminants, such as dirt, moisture, or particulate matter, to enter a system. Such contaminants would otherwise hamper the efficiency of the lubricants, leading to other internal components being subjected to wear and a lessening of their operational efficiency. When an industry’s set place of performance is important, such as aerospace or oil and gas, these signs must be taken care of immediately to stop failures and help productivity.

Unusual Noises as Warning Signs

Unusual sounds in machinery like grinding, squealing, or knocking indicate that something may not be working properly. This may be because components are misaligned, bearings are worn, or parts lack proper lubrication. If not attended to, these noises can escalate into major, costly problems, including complete system failures. Paying attention and taking action early to prevent or resolve root causes keeps me from facing any unplanned downtime and ensures smoother efficiency in operations.

When I hear the sound of something unusual, I first trace the source of the noise and evaluate the degree of urgency. It may be a mere misalignment or additional lubricant needed; however, it should never be ignored without further inspection. Accurately diagnosing helps resolve immediate issues while also preventing further destruction of associated components. These periodic maintenance checks and troubleshooting, more often than not, help keep the prevalence of warning signs at bay.

In the end, I have learned how vital it is to stay in front of issues. By assessing equipment performance and taking any unusual noises seriously as early warnings, I can keep systems at peak performance. Taking good care of the issue immediately often saves machines from becoming nonoperational or having productivity compromised. Doing so averts risks and increases the life span of critical equipment.

Impact on Vehicle Performance

Vehicle performance depends primarily on the status and maintenance of its internal affairs. To maintain peak performance of vehicles, it is extremely important to regularly inspect and promptly address mechanical problems when issues have arisen. Increasingly, lesser concerns, such as worn-out belts or low fluid levels, are being encountered, addressing which can impact fuel efficiency or may give rise to major breakdowns. Safety thus gets compromised with braking systems or steering systems not functioning well. Redressal of these minor issues in time can save repair costs.

To improve the assessment process, the latest technical tools, namely diagnostic software and data-monitoring systems, are applied. This tool gives feedback in real-time concerning important factors of performance-e.g., oil temperature, engine temperature, oil pressure, or battery health-to drivers and technicians so that they remain aware when any possible concern crops up, allowing the matter to be solved beforehand. Furthermore, the more advanced vehicles of today have built-in telematics platforms that analyze vehicle performance data and provide reports. Equipped with this technology, a driver can have their performance monitored and make an informed decision on when to schedule maintenance.

Besides savings, the proper care of vehicle maintenance poses serious operational issues for the environment. A well-maintained vehicle emits less pollution compared to one that has neglected maintenance. For instance, pollutants stemming from a blocked air filter or dysfunctional catalytic converter might cause higher exhaust emissions, which very much contribute to pollution. Adequate maintenance sustains the environment by ensuring that vehicle performance is up to par.

Maintenance and Replacement Tips

Regular Maintenance Practices

- Follow the Manufacturer’s Schedule: It is vital that you adhere to the maintenance period provided in the vehicle’s manual for its best performance. This would consist of oil and lubricant changes, tire rotations, and inspection of parts for any possible wear and tear.

- Check and Replace the Engine Oil: Engine oil works as an agent to lubricate and enable the smooth functioning of several components. Regular oil-level tests and changes will deter wear, promoting greater engine efficiency.

- Check Tire Status: The correct tire pressure and checkup for tread depth stand for fuel-efficient measures and safety improvements. Uneven or inappropriate tires require replacement, balancing the car’s road performance.

- Control the Brakes: The brakes shall need to be evaluated to detect wear signs such as squealing and slow reaction. The brake pads will then be replaced, and the brake fluid checked to offer responsive handling and safety.

- Replace Air Filters: A clogged air filter reduces the engine’s efficiency and results in increased emissions. Intermittent replacement of the air filters would entail better air flow and optimal combustion.

- Keep Fluids at Proper Levels: Coolant, transmission fluid, and windshield washer fluid should be kept topped up or changed asphalt to avoid malfunctions.

Keeping these practices applied alongside being up to date with new car maintenance guidelines will enable a vehicle owner to lower pollution and longevity of their car.

Timely Replacement to Avoid Costly Repairs

Regular maintenance and the timely replacement of crucial components prevent those expensive repairs down the road. A timing belt or chain is one of the most important components that requires attention. If not replaced when recommended by the manufacturer, a worn timing belt can cause extremely costly damage to the engine, such as bent valves or damaged pistons. In like manner, brake pads must be inspected and replaced before endangering safety, or before damaging rotors that would be costlier to repair or replace.

Other components should include spark plugs, battery terminals, and hoses. For example, worn or corroded spark plugs can bring on misfiring and reduce fuel economy. Replacing these at the recommended interval will keep your engine running well. Moreover, damaged and brittle hoses often lead to leaks, overheating, or total system failures. Consistent inspections and replacements can keep these little matters at bay before they turn into serious ones.

With today’s advances in tools and technologies, keeping track of your vehicle’s maintenance needs has become easier. Vehicle apps, automated reminders, and instruments from trusted brands keep updating the user regarding service intervals and the status of their car parts. Combined with a professional vehicle inspection, the car owner can then assess possible problems and work to optimize efficiency while avoiding sudden repair costs. Positive planning and replacement, in due course, save a huge amount of money, adding to safety and the continued use of your vehicle.

Installation Guidelines for Oil Seals

Oil seals must be installed correctly so they can avoid leaking and safeguard the important parts. Follow all the steps below for a successful installation:

- Inspecting the Shaft and Housing: Begin cleaning the shaft and housing very thoroughly. Dirt, grease, or some sort of residue may be found. And now, these surfaces being scratched, dented, or having another imperfection will ruin the seal.

- Selecting the Correct Seal: Check carefully that the oil seal is the correct type, size, and material for the particular application. It must be compatible with the operating environment of heat, pressure, or type of lubrication.

- Lubricate: Apply a light coating of grease or oil compatible with the seal on the new oil seal. One must keep good lubrication for the ease of installation of the seal and to prevent damage to the lip during the first time in operation.

- Adjust the Seal Position: Align the seal with the shaft or the housing in line with the sealing lip to contain the fluid. The majority of the seals will have certain markings that will serve their orientation.

- Use Installation Tools: Use a seal driver that has been specifically designed for the job or a similarly sized tool to press the seal into place evenly. Avoiding all manifestations of excessive force may distort the seal or damage the housing.

- Inspect Installation: After the installation, check that the seal is seated evenly and fully in the housing and that no gap or misalignment may cause leakage.

- Testing the System: At this point, the system should be run at a low speed to verify the functional status of the installation, checking for any leaks or unusual noises. The seal performance should be monitored over a long period to ensure reliability.

Adhering to these details and using high-quality oil seals will ensure the best performance for the system, thus reducing the possibility of premature failure.

Recent Trends in Oil Seal Technology

Advancements in Durable Materials

In recent decades, a considerable body of advancement has been introduced in oil seal technology materials to enhance their durability and operational characteristics. Presently, new generation seals are made from new elastomers and polymer blends that are more resistant to wear and tear, sudden temperature changes, and chemical aggressions. Usually, these are fluoroelastomers (FKM) and hydrogenated nitrile butadiene rubber (HNBR), which are capable of facing stringent conditions in automotive, aerospace, and heavy machinery industries. Hence, by adopting these materials, manufacturers are putting further durability on oil seals, reducing maintenance downtime, and improving system performance.

Further to the new materials that came onto the scene, reinforcement incorporation has played a significant role in providing better strength and dimensional stability for oil seals. Such reinforcements help the seals retain their integrity when they are faced with very high rotational speeds and intense pressures for long hours. On the other hand, advances in nanotechnology gave way to the creation of novel lubricating coatings and fillers designed to reduce friction on mating surfaces. Such features reduce wear and energy consumption due to friction-induced power losses inside the system.

A third factor influencing oil seal material advancement has been the environment. The industry goes on to identify greener alternatives by due consideration of compositions that warrant the smallest possible environmental impact, if any, without compromising performance. For example, research is going on into bio-based elastomers and compounds that can be recycled, emphasising the possibilities of a more eco-friendly alternative to the conventional manufacturing process. Ergo, material science developments, coupled with contemporary engineering, clearly demonstrate the design of oil sealing systems geared toward satisfying sustainability needs besides practical ones.

Eco-Friendly Designs and Innovations

Since eco-friendly design advancements have been brought to the fore, they have prepared the way for an industry transformation into a mode of sustainable existence. Development of green materials, being an area of interest, stands apart from the list. Producers are substituting traditional materials for bio-based polymers, recycled plastics, and natural fibers. These solutions help cut down on petroleum-based resources and cut carbon emissions, especially during manufacturing. Bioplastics from corn or sugarcane, for instance, are biodegradable alternatives that help establish a circular economy and counter materials entering landfills before decomposition. With this focus on green materials, an entirely new approach to sustainable product design is being established.

The other key aspect is energy-efficient manufacturing. Technologies like 3D and additive manufacturing minimize resource consumption by reducing waste and streamlining production processes. They allow manufacturers to produce complex designs only with materials and energy that are strictly necessary. Correspondingly, the increasing usage of renewable power for production facilities—solar power and wind power—has become one of the crucial operations in cutting the reliance on fossil fuel. Such activities would directly endorse the demand of the globe for environmental footprint reduction.

And this is how technology is reshaping green design beyond production: developments in IoT sensors to monitor energy use during the product lifecycle while negating as much environmental interference as possible. Companies are also increasingly factoring in lifecycle assessments (LCAs) in the design stage when assessing product ecological footprints-from sourcing until disposal or recycling, by attacking environmental impact at each stage ofthe production process, companies can come up with fresh ideas that are not only creative but environmentally apt, satisfying both consumer demand and regulatory requirements. In every industry, the quest for greener design attempts to build a more sustainable future.

Enhanced Sealing Capabilities for Modern Vehicles

Sealing technologies have progressed over the years in response to the demands of contemporary vehicles. To guarantee safety, endurance, and efficiency under differing operating conditions, greater sealing capacity is required. These seals are necessary to guard against an outside environment, from water and dust to temperatures, along with stopping the leakage of fluids such as engine oil, coolant, and transmission fluid. Improvements regarding leak-proofing translate to a gain in efficiency, lower maintenance costs, and a longer vehicle life span.

One major improvement in sealing technologies lies in advanced materials and design development. Accordingly, modern seals incorporate high-performance elastomers or composite materials that are capable of resisting extreme environments and prolonged wear. Moreover, novel manufacturing processes, such as advanced injection molding and precision engineering, have enabled seals to be produced within tighter tolerances. The precision fit afforded by these technologies is especially critical to achieving outstanding performance in electric and hybrid cars, wherein seal demand is intensified because of the sensitive battery and electronic assemblies involved.

In addition, sealing systems are being optimized, taking eco-consciousness into consideration apart from functionality. The priority is on environmentally friendly seal materials, including recyclable and biodegradable ones. The digital revolution is then poured into automotive sealing design, providing engineers with computer-aided design (CAD) simulations and finite element analysis (FEA) to test sealing solutions under real-world conditions before production. This synergy between innovation and accountability highlights the role of modern sealing technologies as a prospective force for the automotive industry.

Frequently Asked Questions (FAQ)

Q: What are automotive oil seals?

A: An automotive oil seal is designed to seal the junction between two moving parts, preventing the leakage of oil and grease. They are vital for systems to work properly since the seal keeps the sealing oil inside the system.

Q: How do oil seals work?

A: In general, do oil seals resist the leakage of oil/grease while preventing the ingress of contaminants into the system? They generally have a rubber or elastomeric lip that is pressed or fitted in contact with the rotating shaft to provide sealing to the moving parts for their protection and smooth running.

Q: What are the types of automotive oil seals?

A: Various types of automotive seals include radial shaft seals, grease seals, and double lip seals. Oils seals in varying conditions and environments, seals in different applications, and with oils in their environment and grease.

Q: How do I choose the right oil seal?

A: This becomes the answer to choosing the right oil seal, considering different factors such as size (metric or imperial), hardness, and application specifications. The oil seal should be adapted to the kind of bore and axle to be expected from the vehicle. OEM specifications may guide you, and choosing designs compatible with your vehicle will be beneficial.

Q: What are automotive oil seals made from?

A: Automotive oil seals, generally keen to resist oils and temp. and wear with NBR, have their function disturbed depending on the application, and later for another usage in agricultural machinery and trucks.

Q: Can automotive oil seals be used in agricultural machinery?

A: Yes, agricultural machinery uses automotive oil seals that hold lubricating oil for moving parts primed to dirt and moisture. Oil seals for agricultural applications might change by virtue of the particular machinery and its operating conditions.

Q: What factors should I look at when considering the choice of an oil seal?

A: In considering oil seal selection, take into account factors of seal and lubricant type; oil or grease; environment, which can consist of temperature and exposure to contaminants; and finally, design (single or double lip). In addition, the seal’s specification and suitability for moving parts are very important to ensure minimal leakage and longer durability.

Q: Do oil seals come in different designs?

A: Oil seals do come in different designs based on such features as lip design, hardness of material, and type of seal. Such designs are intended for particular applications, such as applications that require sealing in high-speed or aggressive chemicals; hence, it is pertinent to select the right oil seal for your particular application.

Q: How do I tell if an oil seal is suitable for my application?

A: Suitability for an application is ensured if the specifications for size, material, design type, type of lubricant used (viscous oil or grease), and operating conditions are considered to ascertain that they shall perform effectively, preventing any leakage from occurring.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8