ABEC 5 vs 7: Understanding Skateboard Bearings and Their Ratings

Every aspect that impacts the ride needs to be considered in the wheels, bearings, and trucks. However, bearings are something that people usually overlook because they are so small. Common bearing ratings you’ll usually encounter are ABEC 5 and ABEC 7. These are talked about a lot but are widely misunderstood among skaters. What do these mean? Do they affect the way you ride? Should you choose one over the other? This article goes into the technicalities involved in ABEC ratings and why they are important, so you can make a post-modern choice with your skating style and motives. Maybe the key to better performance lies in understanding these bearings for the recreational cruiser or competitive skater.

Introduction to ABEC Ratings

What is ABEC?

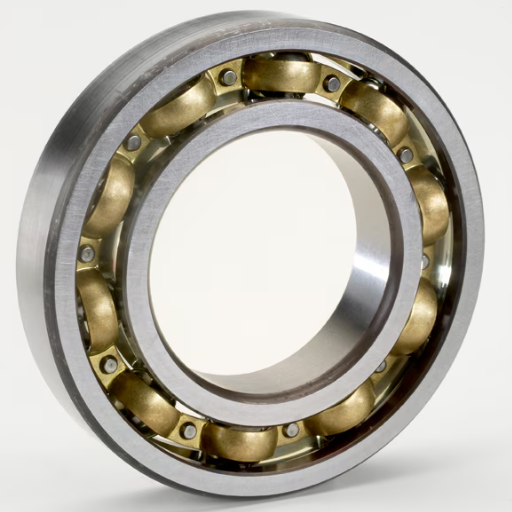

The well-known ABEC (Annular Bearing Engineers’ Committee) system offers a standardized rating protocol used for determining the precision and tolerances of ball bearings employed in mechanical use, such as skates and skateboards. The American Bearing Manufacturers Association (ABMA) instituted the ABEC rating scale for categorization, with major rating levels being ABEC 1, 3, 5, 7, and 9. Theoretically, a higher rating implies tighter tolerances and therefore higher efficiency under specific conditions.

ABEC ratings were thus designed to measure how precisely the bearing was made, dimensionally and in vibration performance. Theoretically, bearings rated on the higher end of the scale would demonstrate very slight deviations in dimensions from the perfect state, i.e., size, shape, and roundness, which would be conducive to less friction during high-speed rotations. On the other hand, the rating does not include assessing issues important for skating performance, such as material quality, lubrication, or resistance to environmental influences such as dirt and moisture.

Even though the ABEC rating has set an industry standard at one time, it does not guarantee that it exactly translates into concrete skating performance. A high ABEC rating bearing is not necessarily “better” for all skaters since requirements vary according to skating style, speed, and surface. For instance, if it involves skaters who do tricks or seemingly ride on rough terrain, they may need bearings that are more durable and easier to maintain, rather than extremely precise. Hence, ABEC ratings, though useful as guidelines, should never be the sole deciding factor in selecting bearings.

The Importance of ABEC Ratings in Skateboarding

The renowned ABEC (Annular Bearing Engineers Committee) system provides a standardized rating protocol for determining the precision and tolerances of ball bearings used in mechanical applications such as skates and skateboards. The American Bearing Manufacturers Association (ABMA) established the ABEC rating standard, with the primary ratings being ABEC 1, 3, 5, 7, and 9. In theory, higher ratings indicate tighter tolerances and, therefore, greater efficiency under specific conditions.

The ABEC rating is therefore intended to measure a bearing’s manufacturing precision, dimensional accuracy, and vibration performance. In theory, higher-rated bearings exhibit minimal deviation from ideal dimensions, shape, and roundness, which helps reduce friction during high-speed rotation. However, the rating does not assess factors critical to skating performance, such as material quality, lubrication, or resistance to environmental influences like dust and moisture.

Although ABEC ratings were once an industry standard, they do not guarantee accurate translation into specific skating performance. Bearings with higher ABEC ratings are not necessarily “better” for all skaters, as skating styles, speeds, and surfaces vary. For example, if an ice skater needs to perform tricks or glide over rough terrain, they may need a more durable and easier-to-maintain bearing rather than an extremely precise one. Therefore, while ABEC ratings can be used as a guide, they should never be the sole determining factor in bearing selection.

Overview of the ABEC Rating System

The ABEC (the Annular Bearing Engineers’ Committee) rating possesses a set of standards used to describe ball bearings’ precision and capability for performance. The numerical scale goes from ABEC 1 to ABEC 9, with larger values representing increasingly close tolerances, or rather, added precision. Bearings with higher experience ratings must, in theory, allow smoothness and have more brilliant efficiency at large speeds. On the flip side, the ABEC system tests only rotational accuracy and tolerances, representing ideal conditions and ignoring other factors affecting performance, such as endurance, quality of materials, or even lubrication.

When considering an ABEC rating, some limitations should be kept in mind. For instance, whereas higher ABEC ratings might indicate better at certain places, this does not imply they make the most wonderful bearing all the time. In skateboarding, where abrasive forces are put on bearings through impacts, dirt, and vibrations, material strength and sealing could very well be more vital than just tight tolerances. Hence, ABEC ratings by themselves do not cover a bearing’s complete usefulness or performance in an active, dynamic, real-world condition.

Bearing choice outside their ABEC ratings requires the review of other factors; among these: the planned use, the working environment, and bearing design features relevant to that environment (such as shields or seals). Taking a sensible approach, incorporating the ABEC rating with dynamically free opinions and requirements, will enable users to choose well enough for an increased bearing performance, efficiency, and longevity.

Comparing ABEC 5 and ABEC 7 Bearings

Key Differences Between ABEC 5 and ABEC 7

The key differences between the ABEC 5 and ABEC 7 bearings are as follows: While ABEC 7 bearings have tighter tolerances and carry a theoretically smoother and faster spin, an ABEC 5 bearing is more universal, durable, and can take rougher treatment.

|

Aspect |

ABEC 5 |

ABEC 7 |

|---|---|---|

|

Tolerance |

Moderate |

Tight |

|

Speed |

Moderate |

High |

|

Durability |

High |

Moderate |

|

Surface |

Rough |

Smooth |

|

Cost |

Lower |

Higher |

Performance and Velocity: ABEC 5 vs ABEC 7

That is the major performance and velocity difference you want to find between ABEC 5 and ABEC 7 bearings. A more theoretical spin for ABEC 7 bearings contains smoothness and velocity, while ABEC 5 bearings are quite strong and were built with a broader sort of applications in mind.

|

Aspect |

ABEC 5 |

ABEC 7 |

|---|---|---|

|

Speed |

Moderate |

High |

|

Smoothness |

Moderate |

Excellent |

|

Durability |

High |

Moderate |

|

Friction |

Moderate |

Low |

|

Surface |

Rough |

Smooth |

|

Cost |

Lower |

Higher |

Resilience and Longevity of Skate Bearings

Several main parameters affect the ability of skate bearings to withstand abuse and their ultimate lifespan. The main factors are material composition, maintenance, and environmental factors on which they are used. Bearings comprising hardened steel or ceramic types exhibit the highest potential for durability through adept resistance to wear and corrosion. Ceramic bearings provide wonderful heat resistance and bear the structural integrity during high-stress scenarios and thus remain suitable for high-performance, high-stress configurations.

Maintenance becomes an important factor in prolonging the service life of skate bearings. It includes ensuring that the bearings are periodically cleaned of debris and dirt and adequately lubricated to operate on a minimum friction coefficient. Lack of maintenance may result in bearing contamination and high friction levels, thereby accelerating their wear thereby reducing performance. Furthermore, environmental exposure through moisture and abrasive grounds can adversely affect bearing integrity, which makes control of environmental factors relevant during usage.

Statistics have it that a high-precision bearing, such as the ABEC 7 and ceramic hybrid, would require a more consistent maintenance pattern to ensure prolonged life because of their vulnerability to contaminants. Conversely, an ABEC 5 bearing is comparatively harder and kind of forgiving under less ideal conditions, but at the expense of speed and smoothness. By selecting the bearings in conjunction with the bearing application, the user can attain a good compromise between performance, longevity, and cost.

Applications of ABEC 5 and ABEC 7 Bearings

Best Uses for ABEC 5 Bearings

Bearings with ABEC 5 rating may be widely accepted for the balanced property and hence are used where moderate precision and durability are required without very high limits on the rotational speed. In situations demanding more strength than extreme sensitivity, these bearings are put to use. Some typical applications of ABEC 5 bearings include bicycles, conveyors, and powered tools, where smooth operation, robustness, and durability are considered necessary, and precise operation to the utmost level is considered an option. In comparison to high-hardness coarse ones with much tighter tolerances, these with loosened tolerances operate reliably even when conditions slightly contaminate loads.

An important quality of ABEC 5 bearings is that they can run under widely varying operational conditions. They suit applications where enforcing regular maintenance may be questionable since the design can accept a degree of wear and tear, yet remains in working order. Skateboards also exemplify a landmark ABEC 5 bearing application, where balancing performance with resiliency yields adequate speed for leisure uses while still standing up to impacts and debris.

Cost efficiency is an enabler again in cementing popularity amongst commercial-grade machinery and tool installation,s as ABEC 5 bearings maintain reliability even when budget constraints creep in. Workshops run a lot of power tools and machinery using ABEC 5 rated bearings for a fair amount of performance, unlike bearings rated ABEC 7 or higher. This trade-off between speed and price ensures ABEC 5 bearings remain a working solution in quite a wide array of practical applications.

When to Choose ABEC 7 Bearings

ABEC 7 bearings are designed for applications demanding the utmost precision, very low friction, and high smoothness of operation. In such cases, ABEC 7 bearings would be needed when rotation must occur at very high speeds under stringent tolerances and with minimum vibrations. The exporting industries could include the aerospace sector, precision robotics, and medical instrumentation industries, like imaging devices, in addition to some special machining equipment requiring extreme accuracy.

Due to the elevated manufacturing standards of an ABEC 7 bearing, tight tolerances are maintained to enable infiltration movement and greater efficiency, which are required in situations where a few imperfections can cause operational failures or inaccuracies. An Aerospace System, for example, might require such bearings to ensure stability and precision for safety, longevity, and functionality of longer duration.

On the other hand, the selection of ABEC 7 bearings also has to weigh the cost for the performance benefit. These bearings are quite costly compared to the lower grades since they use specialty materials, advanced manufacturing techniques, and very stringent quality control. Thus, the most cost-efficient use of these bearings will be where the successful outcome of an operation is directly dependent on their performance.

Proper handling, lubrication, and maintenance must be ensured when using ABEC 7 bearings, as their performance can be affected when the bearings are contaminated or the operational conditions are not to the required standard. Users can assess whether or not ABEC 7 bearings would be the best choice by assessing the precision requirements and operational demands for any given application.

Comparing with Other ABEC Ratings (ABEC 3, ABEC 9)

The main difference when comparing ABEC ratings is that ABEC 3 is very basic and durable for harsh treatment; ABEC 5 makes an ideal balance between performance and cost; ABEC 7 provides smooth surfaces with extreme precision and speed; meanwhile, the ABEC 9 was built for the highest of precision but can very rarely be used for any good by a skateboarder.

|

Aspect |

ABEC 3 |

ABEC 5 |

ABEC 7 |

ABEC 9 |

|---|---|---|---|---|

|

Precision |

Low |

Moderate |

High |

Very High |

|

Speed |

Low |

Moderate |

High |

Very High |

|

Durability |

High |

High |

Moderate |

Low |

|

Friction |

High |

Moderate |

Low |

Very Low |

|

Surface |

Rough |

Mixed |

Smooth |

Ideal Only |

|

Cost |

Lowest |

Lower |

Higher |

Highest |

Factors to Consider When Choosing Skate Bearings

Understanding Precision and Precision

Precision in skate bearings is about manufacturing standards and methods of manufacture that directly go into the performance of the bearing. Higher precision bearings with their ABEC rating have tighter tolerances and allow for smoother and more even rotation at higher speeds. Hence, designing for precision includes giving maximum effort to reduce imperfections like uneven surfaces or gaps that might cause friction or instability.

Besides precision, tolerance acts together with it. It defines the deviation that is admissible from true design specifications. Bearings having very tight tolerances will not wobble easily or lose efficiency even under stress, thus making them the best choice in high-speed applications like downhill racing or professional skateboarding. However, these bearings might offer less long-term durability in rough or uneven terrains owing to their high sensitivity to impact or debris.

As you select bearings, knowing how precision and tolerance relate to your particular use case is key. For example, ABEC 7 or ABEC 9 bearings, with a high level of precision, deliver superb performance on smooth surfaces; however, they are prone to damage or excessive wear under off-road or rugged conditions. Meanwhile, ABEC 3 or ABEC 5 bearings, though limited in precision, enable durability that makes them suited for mixed-surface situations. Such a balance will optimize performance and longevity as per the specific skateboarding requirements.

Choosing the Right Bearing for Your Skate Style

The selection of bearings for your skateboard needs to consider your style of skating, as this will directly affect how you perform on the board. Technical street skateboarders generally require bearings to sustain constant impacts and varying forces. While with many applications one would desire precision, in this respect, durability always supersedes precision. ABEC 3 or ABEC 5 bearings are generally preferred because they can handle rough treatment without failure.

Top-of-the-line precision and higher rotational efficiencies are considered more attractive features by downhill or speed-skaters to provide the smoothness and velocity their sport demands. For this reason, ABEC 7 or ABEC 9 bearings are recommended. These bearings help in minimizing friction and thereby reach high rotational speeds with little resistance; they allow for highly adjustedidiousness that is needed during a controlled high-speed downhill race. However, since these most precise bearings require higher maintenance, and the dirt and debris could damage them, all this bestows on the skating environment a priority on cleanliness and upkeep.

Finally, for the skater who frequents the skateparks or cruises around in differing conditions, a versatile setup is a key point. Such a setup ABEC 5 offers: medium precision level for smoother rides and durability for a bit of off-road or mixed terrain exposure. In addition, many skateboarders are now leaning towards ceramic bearings for their additional benefits of lighter weight, corrosion resistance, and greater longevity. Knowing these options , coupled with good cleaning and lubrication practice, ensures that the bearings suit your skating style and perform optimally at any time after being set. Therefore, having evaluated your skating objectives and environmental conditions, a bearing selection can be made that will address both short-term technical needs and long-term durability.

Expense Considerations: ABEC 5 vs ABEC 7

The price consideration is that ABEC 5 bearings are cheaper and more versatile, but ABEC 7 bearings are way more expensive to manufacture and provide higher precision and speed for certain applications.

|

Aspect |

ABEC 5 |

ABEC 7 |

|---|---|---|

|

Cost |

Lower |

Higher |

|

Value |

High |

Moderate |

|

Durability |

High |

Moderate |

|

Precision |

Moderate |

High |

|

Use Case |

General |

Specific |

Common Misconceptions About ABEC Bearings

ABEC Ratings and Their Impact on Performance

Talking about ABEC ratings, these figures measure mostly the tolerances and precision of ball bearings. The higher the ABEC rating, the tighter will be the tolerances of the bearing, thereby enabling the bearing to run more smoothly at high speeds. Nevertheless, the ABEC ratings do not consider all aspects of performance: materials, lubrication, or load capacity, among other things. This is an important distinction to make when comparing the usability of one bearing against another in a particular bearing application.

In my view, ABEC ratings stand as a good guideline, but really shouldn’t be used on their own when selecting a bearing. ABEC 7s, for example, are more precise but might be overkill in a scenario where extreme speed or precision isn’t necessary. ABEC 5s, on the other hand, are considered more rugged and cheaper to use for general-purpose applications, thus making them a middle ground between performance and cost.

In the end, the superiority provided by ABEC ratings depends on the context of their use. Bearings with low ABEC ratings can give very good performance in scenarios where environmental issues or load outweigh the need for the tightest tolerance. Weighing tradeoffs versus importance to operational requirements is paramount in choosing the appropriate bearing in any given instance.

Debunking Myths About Bearing Velocity

One more encountered misconception on bearing velocity is that the greater the speed, the better the performance. While a high velocity indicates that a bearing can run efficiently under fast-moving situations, it does not imply that this is the best factor to determine the bearing’s total performance. Bearing velocity, which is generally given in terms of a maximum dN-value (product of bearing bore diameter in mm and RPM), sheds some light on its operating limits but always needs to be looked into with respect to load, lubrication, and thermal conditions.

For instance, higher speeds for bearings mean increased frictional heat; if this heat is not managed, it may impair lubrication, hamper efficiency, or, in some cases, lead to premature failure of the very bearing under consideration. On the contrary, bearings being run at lower velocities but higher loads will prefer durability through optimum material selection and specific coatings versus speed.

High-speed bearing technology, by means of engineering innovations, has also evolved such that advanced design considerations can make bearings more thermally stable and resist wear during high-rate rotations. However, such designs are never cheap and require maintenance considerations, again weighing a bearing’s velocity specification against the criteria of its actual application instead of looking at speed performance alone.

Bearing velocity has a somewhat more critical bearing on performance than high-speed capability. It is a careful consideration of the more application-specific requirements that talk of effective operation, which balances speed against the load-bearing capacity, environmental exposure, and the desired life.

Frequently Asked Questions (FAQ)

Q: What are the major differences between an ABEC 5 and an ABEC 7 bearing?

A: The difference between an ABEC 5 and an ABEC 7 bearing is mainly in precision and tolerances. Tighter tolerances enhance the performance of ABEC 7 bearings, particularly at higher speeds. This greater precision reduces friction, thereby increasing inertia; hence, ABEC 7 is more preferred for high-speed applications, such as longboard bearings.

Q: What does ABEC stand for?

A: The abbreviation ABEC stands for Annular Bearing Engineering Committee. It is a term used to describe the standards by which the precision of rolling bearings is rated. The ABEC scale has different degrees; the most common being ABEC 1, 3, 5, and 7, where a higher number means more precision and less tolerance.

Q: How do ABEC ratings affect bearing performance?

A: The ABEC rating system is a measurement of bearing precision. Bearing with a higher ABEC number, like ABEC 7, means it has been made with a smaller tolerance and can provide higher speed and smoother running. But this certainly can add to the performance of high-precision applications, like on a skateboard or on some other high-speed device.

Q: What are ABEC 5 bearings the best for while longboarding?

A: These bearings can be used for casual longboarding, as ABEC 5 bearings can work, but their performance at high speed may be less compared with ABEC 7 bearings. Instead, if you want almost flawless performance and very smooth rides, you would want to carry ABEC 7 bearings that suspend at higher speeds.

Q: Can I clean ABEC 5 bearings and ABEC 7 bearings?

A: Yes, ABEC 5 and ABEC 7 bearings can be cleaned. Cleaning keeps the bearings free from any dirt and contaminants that can hinder good performance. After cleaning, a suitable bearing lubricant should be applied so that the bearings can function correctly. Cleaning means prolonging the life of your bearings and retaining their precision.

Q: What is the significance of an ABEC scale?

A: An ABEC scale is significant because it provides a standardized classification of the precision of bearings. In doing so, it helps consumers understand the tolerances and performance characteristics of a given type of bearing. For instance, ABEC 7 bearings generally perform better and exhibit tighter tolerances than ABEC 5 bearings, making them a target application for high speed.

Q: How is ISO related to ABEC ratings?

A: The ISO, or International Organization for Standardization, issues standards and guidelines that can be used in conjunction with ABEC ratings. For example, ISO P2 is a standard that defines a precision level for bearings. ABEC describes the tolerances of the bearing, whereas ISO standards are concerned with consistency and quality from one producer to another.

Q: What needs consideration when choosing between ABEC 5 and ABEC 7?

A: Consider the intended purpose and performance required when choosing between ABEC 5 and ABEC 7. If you want a bearing for high-speed applications, then ABEC 7 would be suitable because it is more precise and has with heavier tolerance. However, if ease of use or medium speed is under consideration, the ABEC 5 would be sufficient and cheaper. Q: How do you manufacture ABEC bearings?

A: ABEC bearings are made with specified tolerances and precision in mind. Machining occurs in manufacturing to precisely machine the inner and outer races and the balls that make the bearing. The higher the ABEC, such as ABEC 7, the more attention has to be given, manufacturing-wise, to every little detail to create the required tolerances and performance.

Q: What lubricant is best for ABEC bearings?

A: Lubricants suitable for high-speed use are the best for ABEC bearings. Bearing lubricants will lower the friction and allow the precision of the bearings to remain intact. It is necessary to use a good lubricant that will tolerate the high speeds and conditions the bearings are operating in so that performance can be optimized and longevity assured.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8