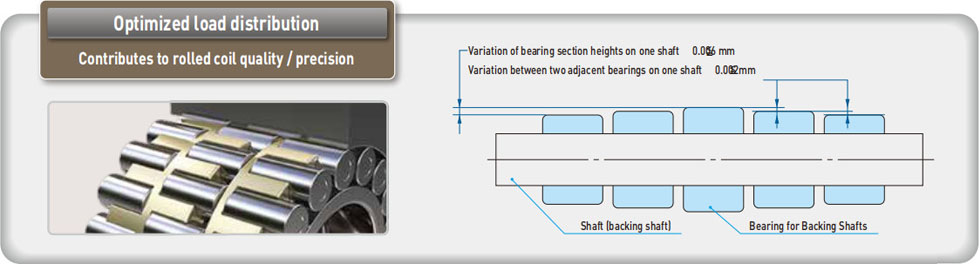

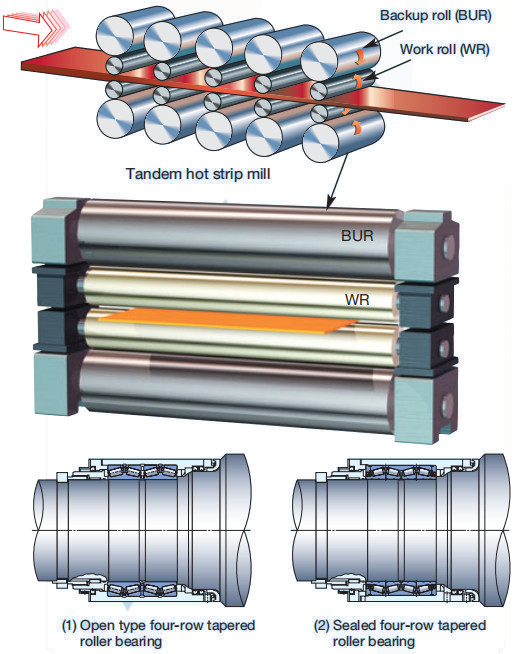

BEARINGS FOR THE STEEL INDUSTRY

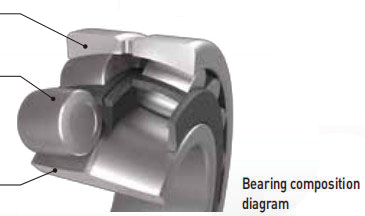

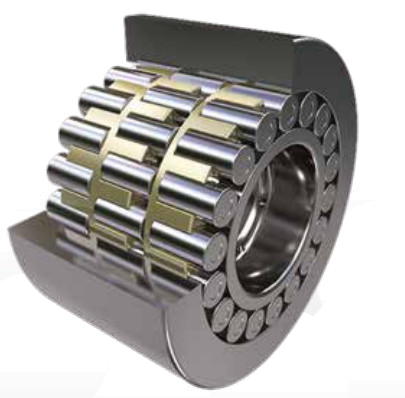

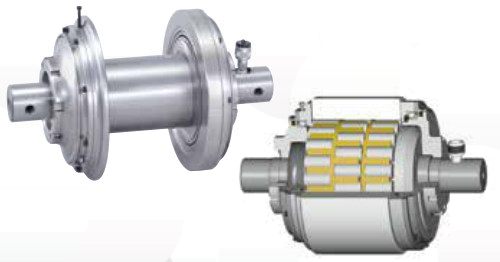

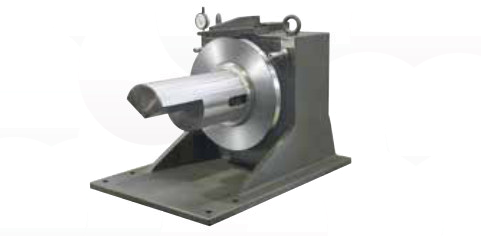

Our bearing solutions and services help ensure reliable and efficient operations across the steel industry, while our bearing team of technologists are always working on the solutions to help take the steel industry to the next level.

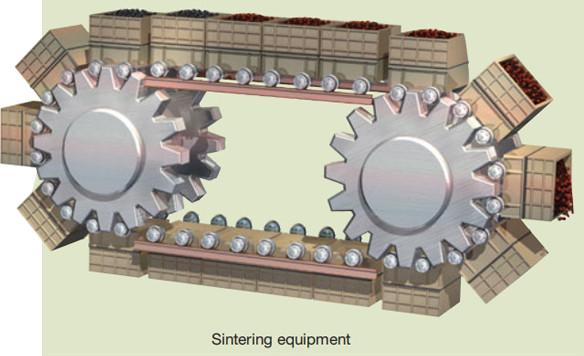

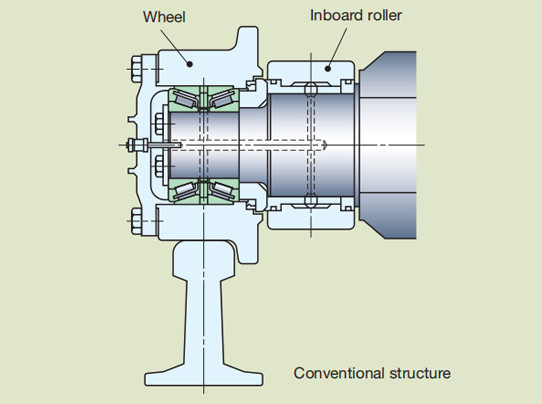

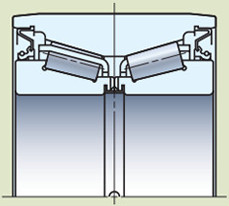

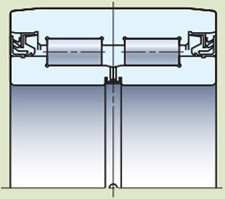

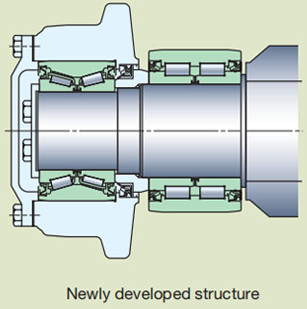

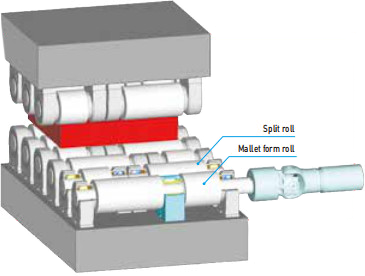

In response to the need for increased productivity and product quality, We offer bearings that have been specially developed for all the relevant conditions encountered throughout the entire process. from raw material storage yard to the steelmaking, rolling and refining processes, Loyal understands the extreme conditions that rolling mills and casting operations face. Using our bearings and mechanical systems expertise, we deliver bearings and machinery parts tough enough to perform reliably in such harsh environments.